GE P&W FuelSolv - Opportunity Coal Slag Control at Lakeland McIntosh Unit #3 User Manual

Page 6

Page 6

Technical Paper

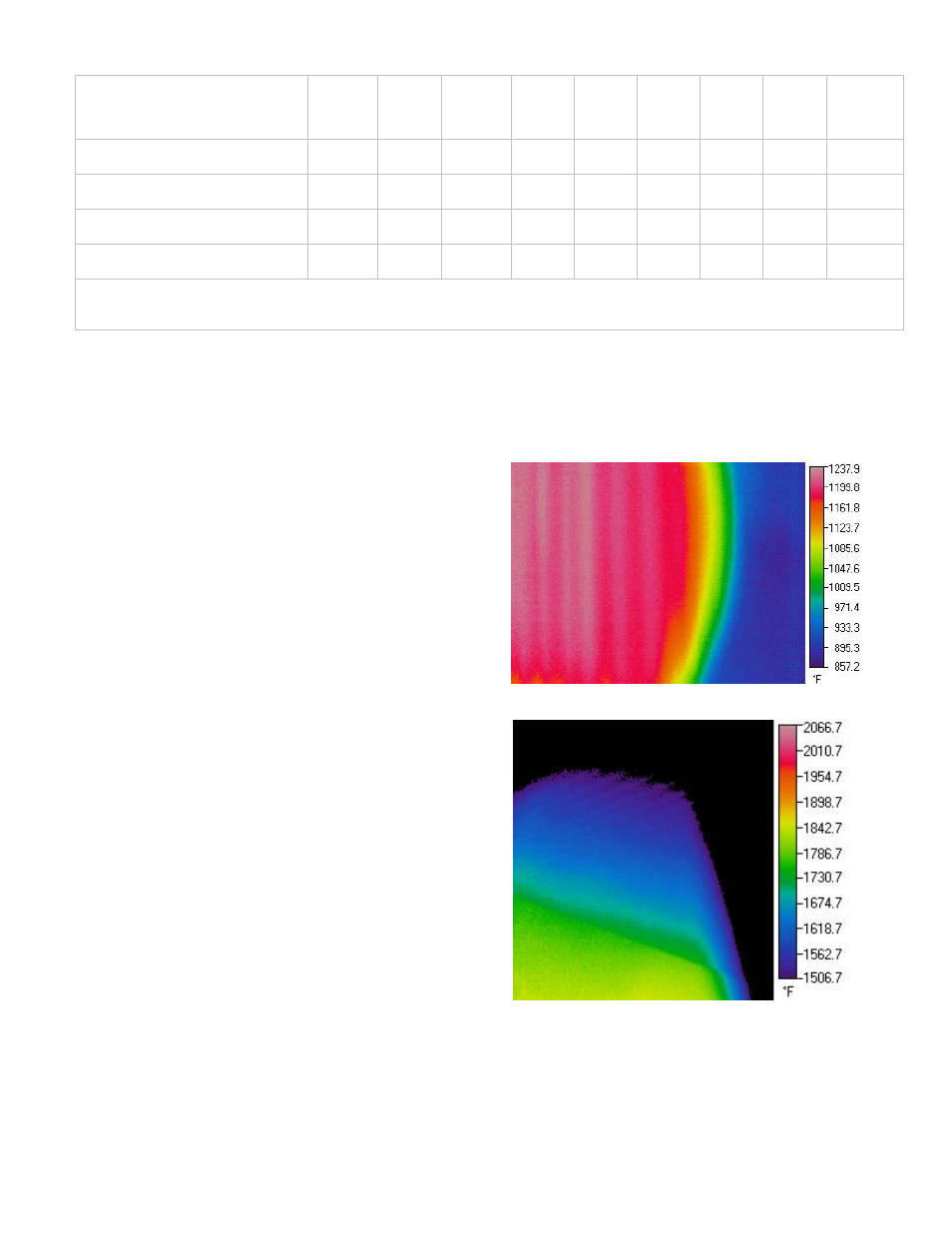

Visual & Infrared Photography

The trial team used port inspection and photog-

raphy to monitor boiler slagging conditions in the

furnace. The team developed a standardized nam-

ing convention for referencing boiler ports at vari-

ous elevations. For example, port “8A” refers to Level

8, Port A. This system ensured that slagging condi-

tions were properly recorded since more than a

dozen trial team members viewed, photographed,

and commented on the visual conditions in dozens

of observation ports during the trial.

Visual and infrared (IR) photos of conditions at the

various boiler elevation ports were recorded. Visual

photos were made with an Olympus** brand “point-

and-click” digital camera and IR images were gen-

erated by a Mikron LumaSense*** Model 7604F in-

frared camera. The camera’s integral flame filter

and high temperature range covered the boiler’s

operating range (up to 3,000 deg F). In addition, the

multi-spot temperature measurement capability

enabled final images to include reference tempera-

ture profiles. (Mikron, 2011) Thermal photos of the

boiler slag conditions were recorded at the boiler

ports throughout the trial.

Not only were visual observations of these condi-

tions important, they were, arguably, the best way

to measure the impact of chemical treatment on

boiler slag, since instantaneous changes in many

variables (such as sootblower activity, number of

pulverizers in operation, load changes, etc) make it

difficult to compare with other parameters in isola-

tion (such as FEGT).

Several photos of the slagging conditions in the

boiler at the start of the trial (Figures 9 and 10) clear-

ly show the bottom of the superheater (SH) pendant

with no or minimal slag accumulation during base-

line conditions.

Overall slagging was considered minor at the start

of the trial, and the team increased the percent-

age of opportunity coal. Visual spectrum photos

are provided in Figures 9-13.

Figure 9: Superheater, Floor 9.5 Port A (5-17-11)

Figure 10: Under “Bullnose”, Floor 8 Port D (5-17-11)

PARAMETERS

(start – end dates)

5/17 –

5/19

5/23 –

5/25

5/31 –

6/1

6/1 –

6/2

6/3 –

6/4

6/5 –

6/6

8/4 –

8/21

12/5 –

12/9

12/12 –

12/16

NAPP Coal Percentage

12.5%

25%

50%

66%

75%

50%

75%

ILB Coal Percentage

50%

75%

Magnesium product, lbs/ton

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

Metal oxide product, lbs/ton

0.25

0.25

0.25

0.25

0.25

0.25

0.25

0.25

0.25

Figure 8: Lakeland McIntosh Unit #3 Trial Schedule with CAPP Coal and Opportunity Coal blends

(Boiler at Full Load and Experiencing “Acceptable” Low Slag Conditions)