Ocv estimation and coulomb-count mixing, Fuel-gauge empty compensation, Fuel-gauge learning – Rainbow Electronics MAX17047 User Manual

Page 10: Figure 3. modelgauge m3 ocv and coulomb, Figure 4. modelgauge m3 algorithm mixing

���������������������������������������������������������������� Maxim Integrated Products 10

MAX17047

ModelGauge m3 Fuel Gauge

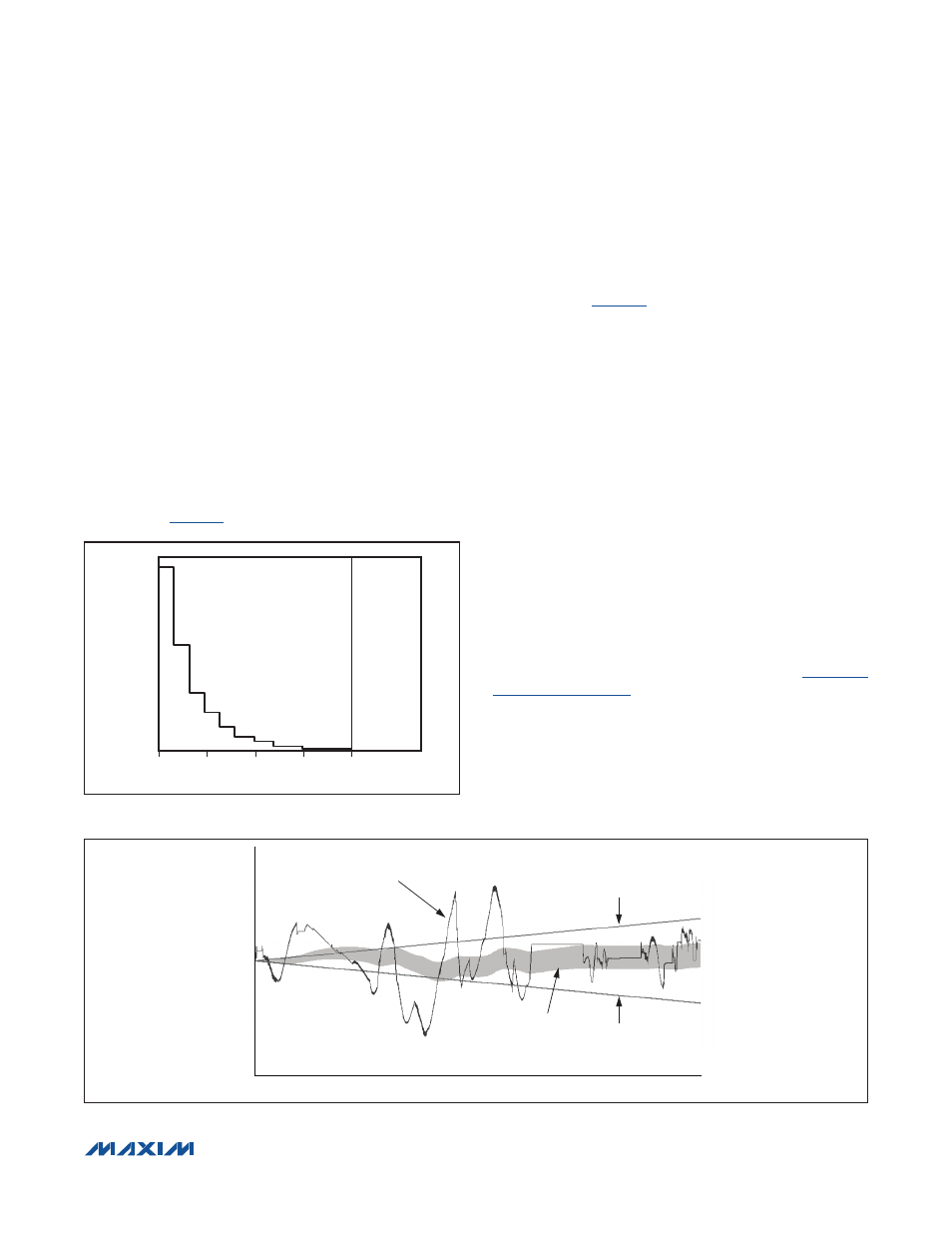

Figure 4. ModelGauge m3 Algorithm Mixing Conceptual Illustration

OCV Estimation and Coulomb-Count Mixing

The core of the ModelGauge m3 algorithm is a mixing

algorithm that combines the OCV state estimation with

the coulomb counter. After power-on reset of the IC,

coulomb-count accuracy is unknown. The OCV state

estimation is weighted heavily compared to the coulomb-

count output. As the cell progresses through cycles in

the application, coulomb-counter accuracy improves

and the mixing algorithm alters the weighting so that the

coulomb-counter result is dominant. From this point for-

ward, the IC switches to servo mixing. Servo mixing pro-

vides a fixed magnitude error correction to the coulomb

count, up or down, based on the direction of error from

the OCV estimation. This allows differences between

the coulomb count and OCV estimation to be corrected

quickly. See

.

The resulting output from the mixing algorithm does

not suffer drift from current measurement offset error

and is more stable than a stand-alone OCV estimation

algorithm; see

. Initial accuracy depends on the

relaxation state of the cell. The highest initial accuracy is

achieved with a fully relaxed cell.

Fuel-Gauge Empty Compensation

As the temperature and discharge rate of an applica-

tion changes, the amount of charge available to the

applica tion also changes. The ModelGauge m3 algo-

rithm dis tinguishes between remaining capacity of the

cell (RemCap

MIX

) and remaining capacity of the appli-

cation (RemCap

AV

) and reports both results to the user.

Fuel-Gauge Learning

The device periodically makes internal adjustments

to cell characterization and application information to

remove initial error and maintain accuracy as the cell

ages. These adjustments always occur as small under-

corrections to prevent instability of the system and

prevent any noticeable jumps in the fuel-gauge outputs.

Learning occurs automatically without any input from the

host. To maintain learned accuracy through power loss,

the host must periodically save learned information and

then restore after power is returned. See the

section for details:

• Application Capacity (FullCAP). This is the total

capacity available to the application at full. Through the

user-defined registers, ICHGTerm and FullSOCThr,

the device detects end-of-charge conditions as the

cell is cycled. These points allow the device to learn

the capacity of the cell based on the charge termina-

tion experienced during operation.

Figure 3. ModelGauge m3 OCV and Coulomb-Count Mixing

CELL CYCLES

OCV AND COULOMB-COUNT

MIXING RATIO

1.50

1.00

0.50

0

0%

100%

2.00

COULOMB-COUNT INFLUENCE

SERVO MIXING

OCV

INFLUENCE

TIME

STATE-OF-CHARGE ERROR

(SHADED AREA)

ModelGauge m3

OCV + COULOMB-COUNT MIXING

MAXIMUM ERROR RANGE

MAXIMUM COULOMB-COUNTER ERROR

TYPICAL OCV ESTIMATION

ERROR AS CELL IS CYCLED