Magnavalve – Electronics 590-24 User Manual

Page 9

9

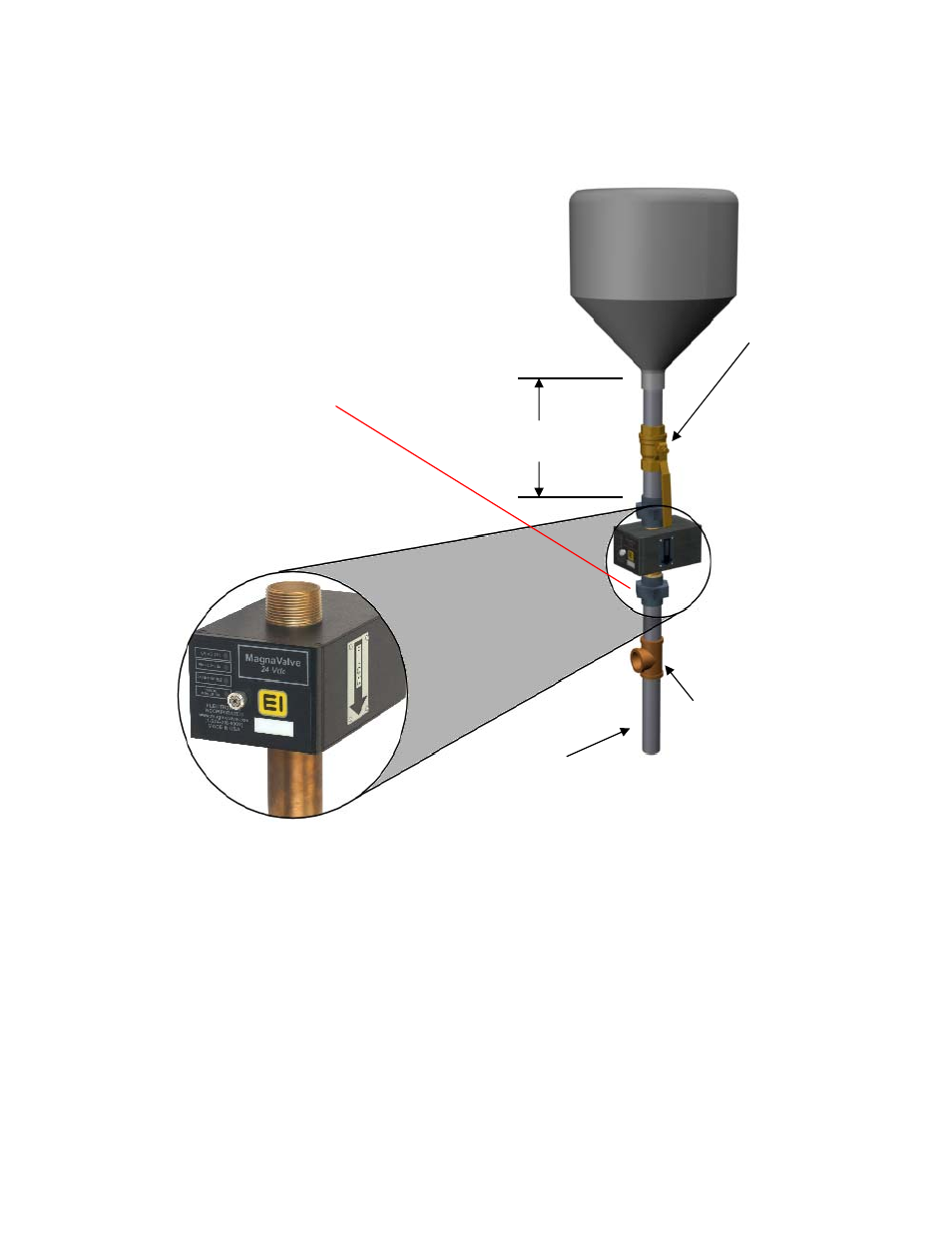

For gravity-assisted applications (valve located on the top of blast cabinet, below the media

hopper) provide an aspiration air inlet, with a recommended minimum opening of 12mm, to

convey the media to the nozzle. Do not restrict this air inlet since it will increase the suction

and may pull media through the valve.

Model *XXXX MagnaValve General Arrangement

For suction-type nozzle applications there is no need to provide supplemental mechanical

valves to isolate the MagnaValve from air pressure. The MagnaValve will to operate with a

maximum 5-psi air pressure differential from top to bottom of the valve. The MagnaValve

has no moving parts, but operates by using a magnetic field to restrict the flow of shot.

During operation the nozzle creates a venturi suction to draw the shot into the nozzle. The

shot hopper is at atmospheric pressure. The MagnaValve dispenses shot into a mixing

chamber (tee) where aspiration conveys the shot to the nozzle. A mechanical shut-off

valve should be located above the MagnaValve to allow it to be removed for clearing of

debris without the shot hopper. The MagnaValve can be enabled at the same time as the

application of air pressure to the nozzle. It is not necessary to sequence the start-up, as in

direct pressure applications

HOSE TO

SUCTION NOZZLE

MIXING TEE

6” MINIMUM

OPTIONAL

MANUAL

SHUT OFF

VALVE

MAGNAVALVE

UNIONS ARE

RECCOMENDED

FOR EASY REMOVAL

OF VALVE