Electronics 590-24 User Manual

Page 4

4

PRODUCT DESCRIPTION

The redesigned 5xx-24 Series MagnaValves provide improved performance and reliability

with an easier calibration mode. MagnaValves regulate the flow of ferrous media in abrasive

blast cleaning and shot peening machines. The 5xx-24 valves have a magnetic control sec-

tion (upper portion) and a shot flow rate sensing section (lower portion). This system of con-

trol makes the valve useful in both Open Loop and Closed Loop systems.

The flow rate ca-

pacity determines the size of the valve, either in lbs/min. or in kg/min. The 5xx-24 Series of

MagnaValves find their use in air-blast applications such as direct pressure, suction blast or

gravity-fed nozzle blast machines.

Specify calibration in

lb/minute or kg/minute,

as well as type and size of

shot with order.

THEORY OF OPERATION

MagnaValves have no moving parts, they rely upon very strong permanent magnets and

cancellation electromagnets to regulate the flow rate of shot. A signal from a shot flow con-

troller, model FC-24, will provide the appropriate control signal for flow rate. The customer

supplies an external 24Vdc power source required to power both the MagnaValve and FC-

24controller. The internal circuitry accepts a 0-10Vdc control signal and converts this signal

to a proportional duty-cycle control of the output signal for shot flow. As the shot falls

through the lower sensing portion of the valve, a 0-10Vdc signal is generated and sent back

to the FC-24 controller as a flow feedback signal. The controller compares this feedback

signal to the requested shot flow rate and adjusts the output signal and sends it back to the

MagnaValve to complete the closed-loop cycle of control.

LOCATION OF ADJUSTMENTS

All of the adjustments are accessible from the front of the MagnaValve (see figure on page

13 for details). It is inadvisable to change the factory settings. The identification label shows

the rated flow range. The calibrated valve produces a 10Vdc output signal at the specified

range, be it calibrated for kg/min or lb/min.

PRELIMINARY ADJUSTMENTS

There are no preliminary adjustments required but, after installation, it is recommended that

the zero adjust on the valve be fine-tuned. The valve is tested and calibrated at the factory

prior to shipment. The product label lists the full-scale range of the valve as well as the me-

dia type and size.

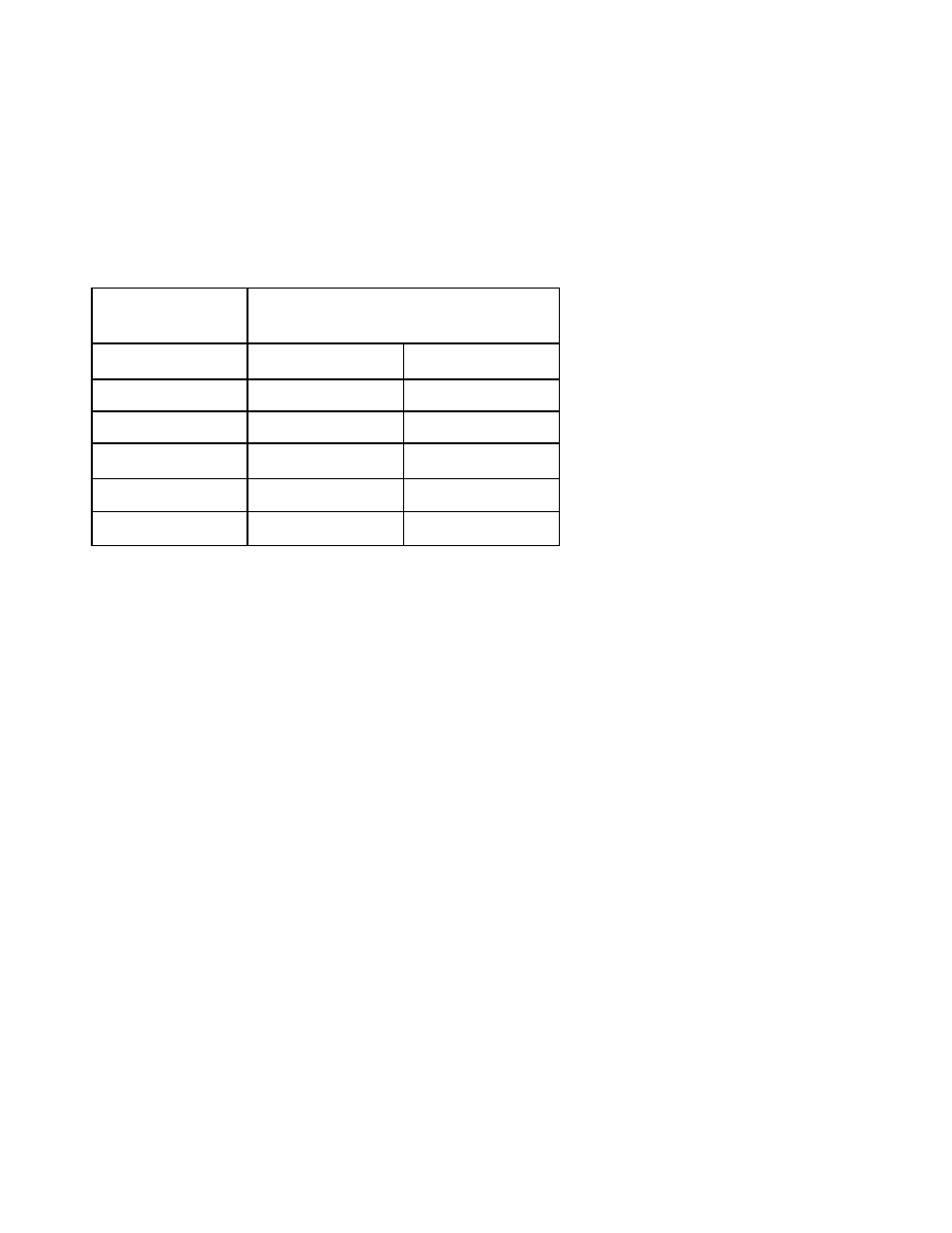

MagnaValve

Model

Flow Range

576-24

2 lbs/min

1 kg/min

578-24

30 lbs/min

13.5 kg/min

579-24

100 lbs/min

45 kg/min

580-24

200 lbs/min

90 kg/min

590-24

300 lbs/min

135 kg/min

577-24

10 lbs/min

4.5 kg/min