Grain Systems Unload Augers PNEG-1049 User Manual

Page 23

4. Assembly

PNEG-1049 10"-12" Commercial Bin Sweep Augers

23

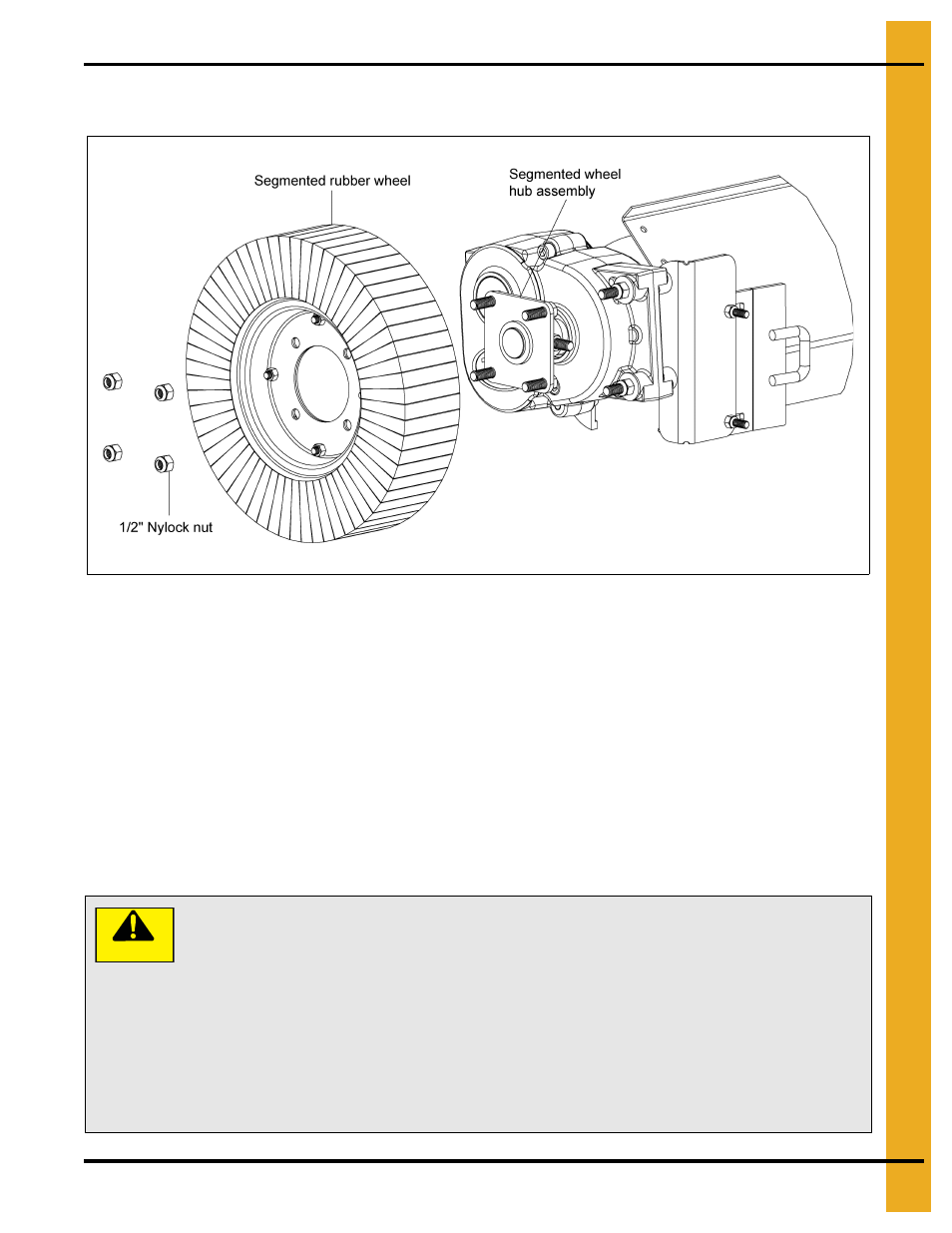

21. Bolt the segmented rubber wheel to the segmented wheel hub assembly with four (4) 1/2" nylock

nuts.

Figure 4R Wheel to Enclosed Chain Drive

22. Make final adjustments to the back shields and mounting brackets and tighten all hardware. Adjust

the carrier wheel assemblies if provided. The carrier wheel assembly should NOT be adjusted to

support the full weight of the flight and shield sections. The carrier wheel assembly should be

adjusted so that it ONLY keeps the flight and back shield from contacting the floor.

NOTE: Failure to properly adjust the carrier wheel assembly as described above can result in

damage to the bin floor and the bin sweep.

23. Inspect the “DANGER” decals on the back shields to ensure legibility. If the decal cannot easily be

read or is missing, order a new decal immediately from the dealer.

24. Fill the 3:1 aluminum enclosed drive with oil. This is accomplished by removing the vented fill plug

and pouring 48 ounces of oil into the drive. The oil level can be checked by removing the check plug

on the opposite side of the drive. The oil level should not be over the check plug.

CAUTION

Oil must be added prior to running the bin sweep. The 3:1 aluminum enclosed

drive is shipped WITHOUT oil.

Do NOT add more oil than is recommended. Additional oil may damage the seals

or be forced out through the vented fill plug.

For lubrication in normal operating temperature between 40°F and 120°F, we

recommend the use of non-foaming, multi-purpose gear oil, SAE 90 weight. For

temperatures below 40°F, use SAE 80 weight oil. Use grade commercially

available for automotive differentials. Extra pressure additives may be of value in

severe applications.