Lifting jack usage – Grain Systems PNEG-1510 User Manual

Page 27

5. Sidewall Construction

PNEG-1510 Top Dry 24', 30' and 36' Manual Batch

27

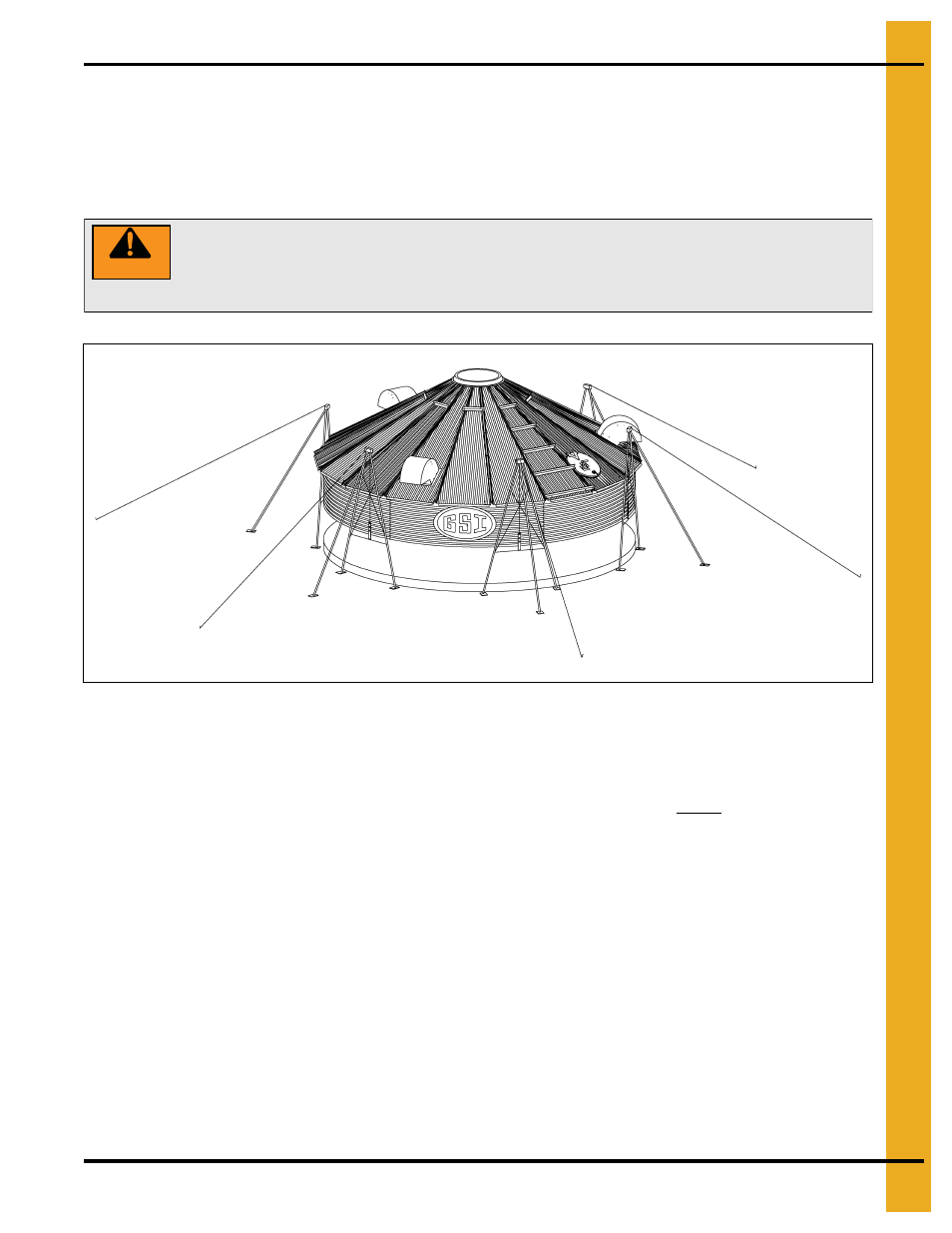

Lifting Jack Usage

Give some thought before starting the bin on location of door and other accessories. Proper placement of

lifting jacks in relationship to anchor bolts could make a difference on odd or even ring bins. Walk-through

door is centered between two (2) stiffener anchor bolts. The sidewall sheets are also staggered 1/2" from

end to end.

Figure 5F

Lifting brackets should be attached to the stiffeners. Normally you will need to attach to at least four (4)

bolts per stiffener. Anchor all jacks securely with metal stakes and cable. Now raise the bin just high

enough to assemble the next ring. When lifting the bin, crank all jacks at an equal rate. This will prevent

bowing previously assembled rings and make for easier hole alignment. To the inside of the first ring, bolt

the next ring. Be sure to stagger the sheets and select the proper gauge material. Lower the bin on the

foundation after assembling and tightening bolts on the new ring or rings. When installing duct work for

the drying fans be sure to install it as you go up with the bin letting the duct set on the foundation before

the bolts are tightened to assure proper alignment. Now re-bolt the lifting straps to the lowest ring in place

thus far. Continue ring additions until you are ready for door installation. You may want to leave sheets

loose to make the attachment of the stiffeners easier.

NOTE: Add inside and outside ladders to bin walls as you continue to raise the bin.

WARNING

The number of lifting jacks required is best determined by personal experience.

Factors such as bin size, soil compaction, wind velocity, jack design, etc., are all

to be considered when deciding how many to use. If in doubt, use one jack on

every vertical seam. Be sure to use heavy duty jacks for commercial installation.