Lubrication procedure, Service – Grain Systems PNEG-1717 User Manual

Page 56

10. Service

56

PNEG-1717 CE Approved GSI/FFI Portable Dryer Manual

Lubrication Procedure

1. Always clean the grease nipple before greasing.

2. On motors with drain plugs, remove plug and operate for 20 minute before replacing drain plug.

3. On motors equipped with slotted head grease screw, remove screw insert 5 cm to 8 cm grease on

NEMA 254 motors and smaller. Insert 8 cm to 13 cm length on larger motors.

NOTE: All of the auger and metering roll bearings are lifetime lubricated.

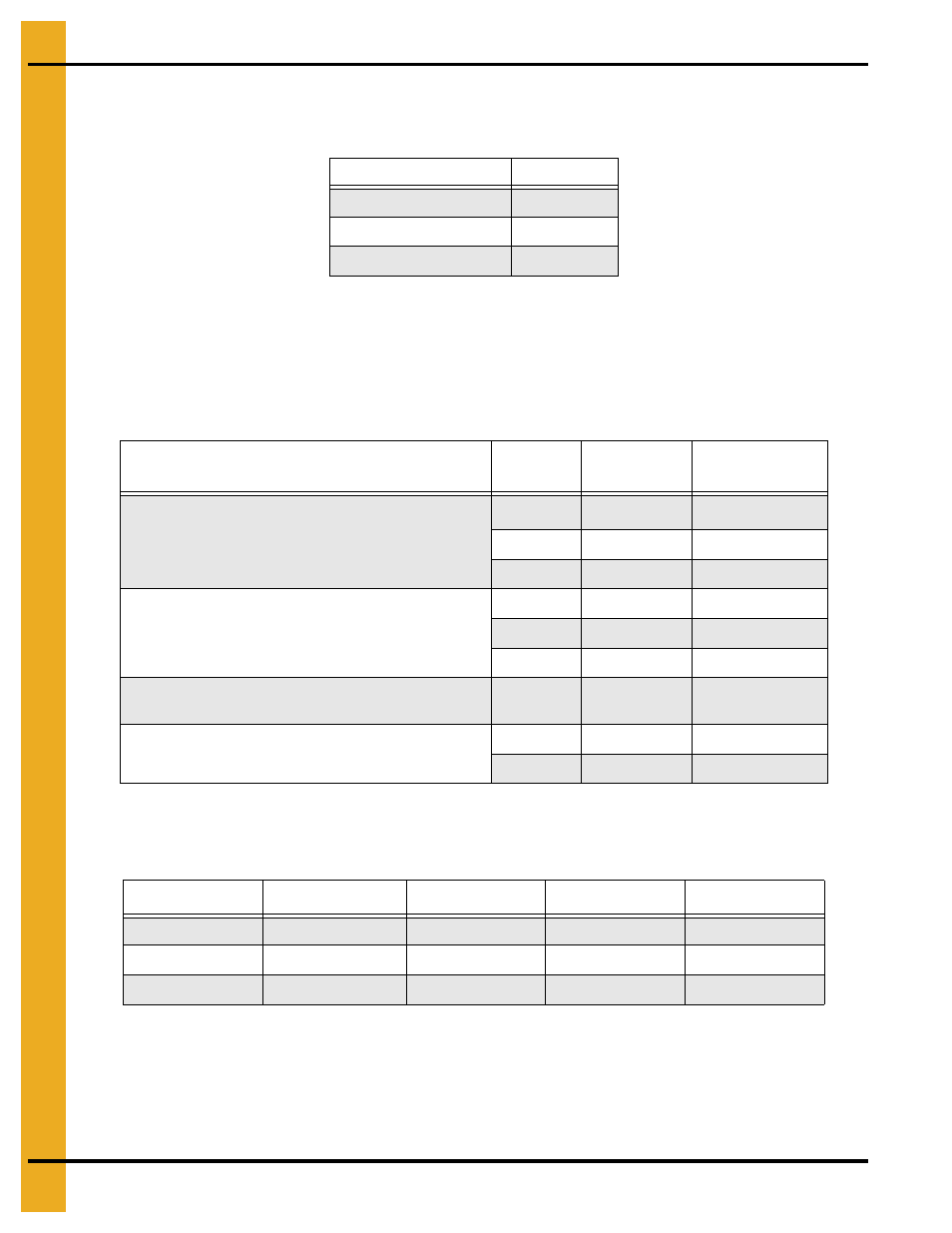

Suggested Lubrication Schedules *

Suggested Lubricant’s

Motor Frame

# Strokes

< NEMA 215

1-2

NEMA 254 - NEMA 365

2-3

> NEMA 404

3-4

Hours of Service per Year

HP Range

Kw Range

Suggested Lube

Interval

5000

1/8 to 7-1/2

0.1 to 5.6

5 Years

10 to 40

7.5 to 29.8

3 Years

50 to 150

37.3 to 111.9

1 Year

Continuous Normal Applications

1/8 to 7-1/2

0.1 to 5.6

1 Year

10 to 40

7.5 to 29.8

3 Years

50 to 150

37.3 to 111.9

9 Years

Seasonal Service (Motor is idle for 6 months or more)

All

All

1 Year - beginning

of season

Continuous high ambient temperatures, dirty or moist

locations, high vibrations or when shaft gets hot.

1/8 to 40

0.1 to 29.8

6 Months

50 to 150

37.3 to 111.9

3 Months

* The bearings have been lubricated at the factory, thus no lubrication should be added before start-up.

Insulation Class

Consistency

Type

Grease

Frame Type

A and B

Medium

Polyurea

Shell Dolium R

215T and Smaller

A and B

Medium

Polyurea

Shell Dolium R

254 and Larger

F and H

Medium

Polyurea

Shell Dolium R

All