2 communication profibus pa, Instrument master file, Id number – VEGA MINITRAC 31 Profibus PA User Manual

Page 84: Cyclical data traffic

84

11 Supplement

MINITRAC 31 • Profibus PA

43836-EN-131119

For that reason the associated approval documents of these instruments must be carefully noted.

They are part of the delivery or can be do and "VEGA Tools" as

w" and "Approvals".

11.2 Communication Profibus PA

Instrument master file

The instrument master file (GSD) contains the characteristic data of the Profibus PA instrument.

These data are, e.g. the permissible transmission rates as well as information on diagnostics values

and the format of the measured value outputted by the PA instrument.

A bitmap file is also provided for the Profibus network planning tool. This file is installed automati-

cally when the GSD file is integrated. The bitmap file is used for symbolic indication of the PA instru-

ment in the configuration tool.

ID number

Each Profibus instrument gets an unambiguous ident number (ID number) from the Profibus user

organisation (PNO). This ID number is also included in the name of the GSD file. Optionally to this

manufacturer-specific GSD file, PNO provides also a general so-called profile-specific GSD file. If

the general GSD file is used, the sensor must be set to the profile-specific ident number via the DTM

software. By default, the sensor operates with the manufacturer-specific ID number. When using the

instruments on a segment coupler SK-2 or SK-3, no special GSD files are required.

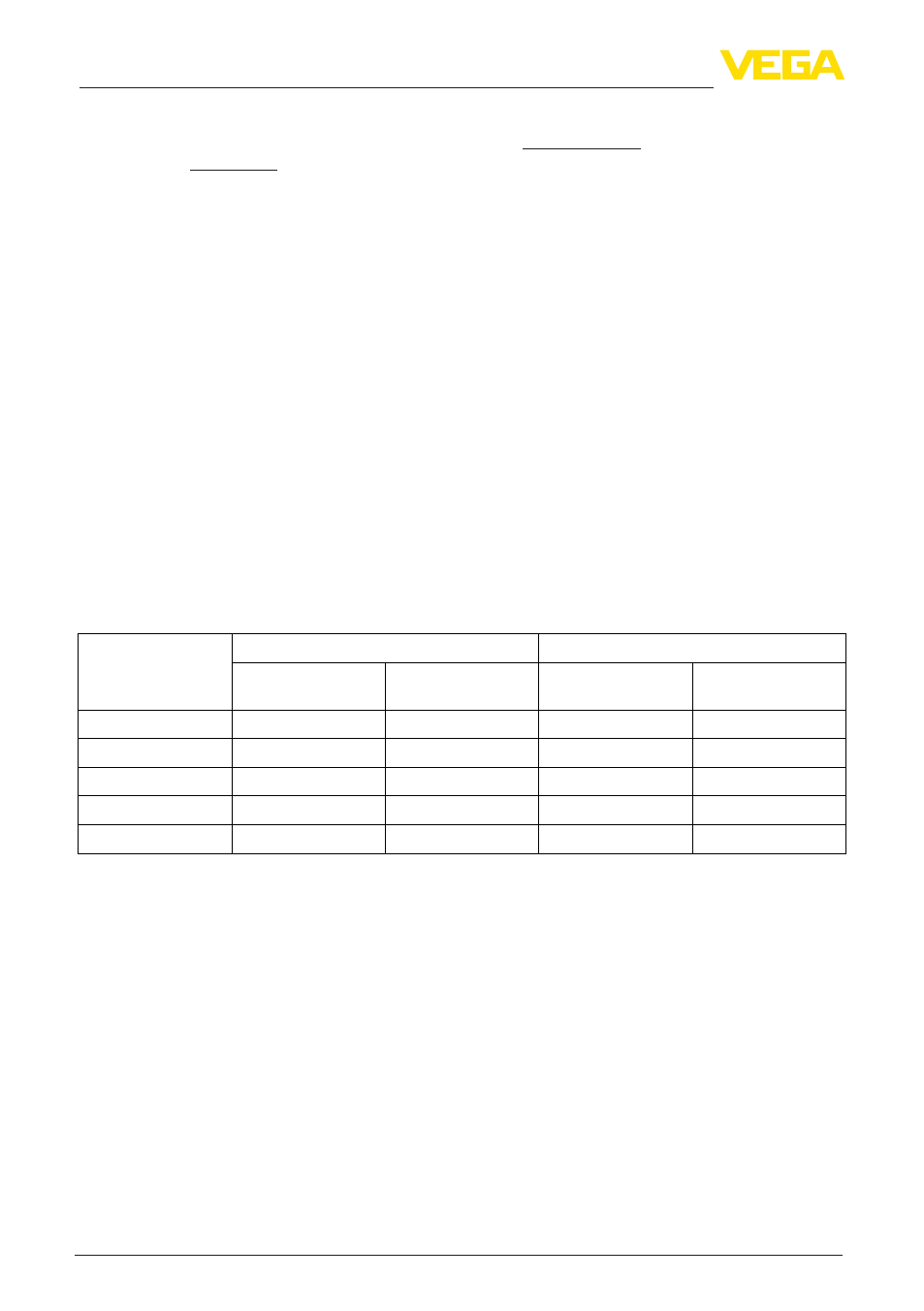

The following table shows the instrument ID and the GSD names for the PROTRAC sensor series.

Device name

Instrument ID

GSD file name

VEGA

Instrument class in

profile 3.02

VEGA

Profile-specific

MINITRAC 31

0xCF5

0x9702

VE010CF5.GSD

PA139702.GSD

FIBERTRAC 31

0xCF2

0x9702

VE010CF2.GSD

PA139702.GSD

SOLITRAC 31

0xCF4

0x9702

VE010CF4.GSD

PA139702.GSD

POINTRAC 31

0xD48

0x9702

VE010D48.GSD

PA139702.GSD

WEIGHTRAC 31

0xCF8

0x9702

VE010CF8.GSD

PA139702.GSD

Cyclical data traffic

The master class 1 (e.g. PLC) cyclically reads out measured values from the sensor during opera-

tion. The below block diagram below shows which data can be accessed by the PLC.