3 rectify faults – VEGA MINITRAC 31 Profibus PA User Manual

Page 75

75

9 Diagnostics and service

MINITRAC 31 • Profibus PA

43836-EN-131119

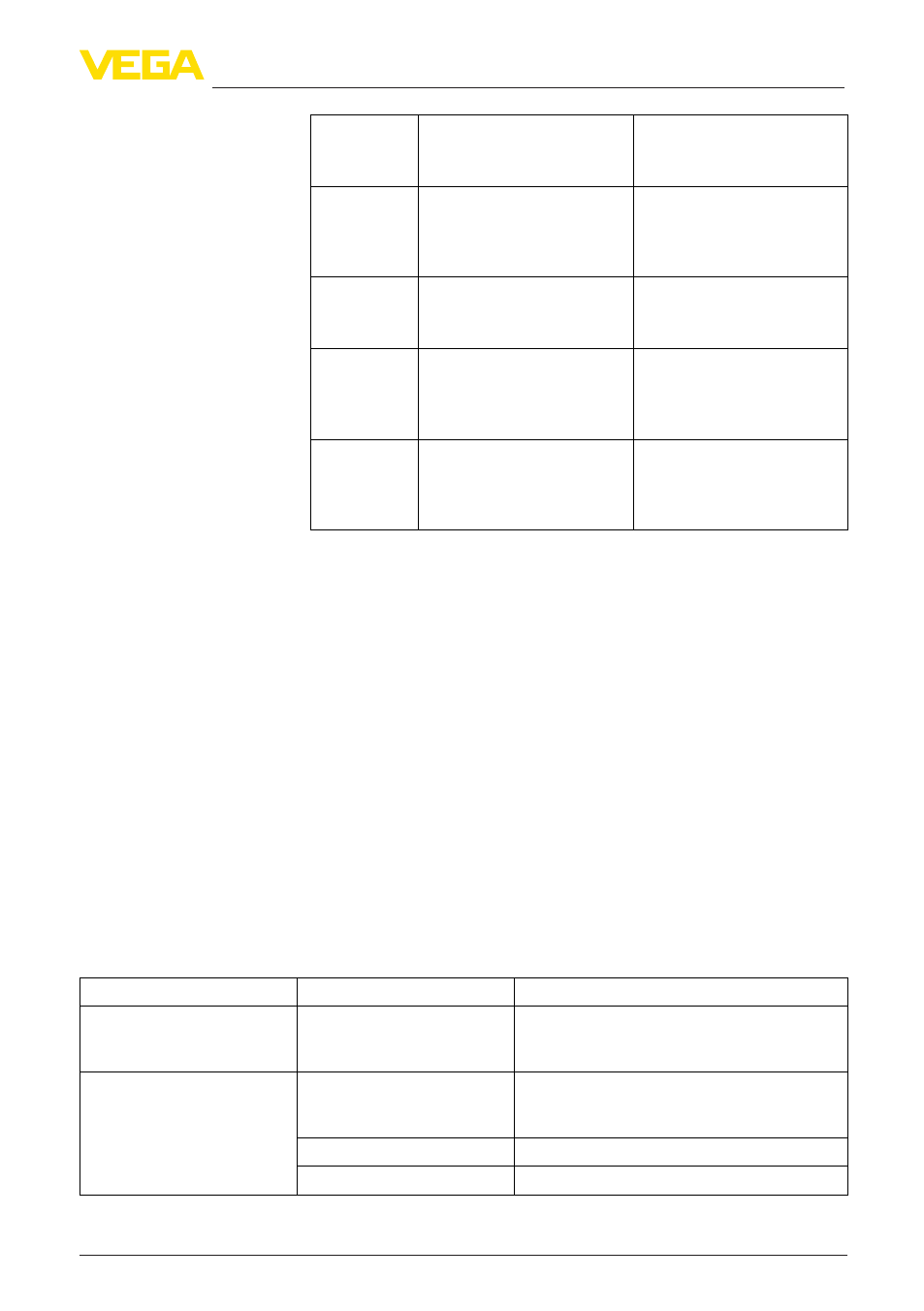

Code

Text mes-

sage

Cause

Rectification

S017

Accuracy

outside the

specification

– Accuracy outside the

specification

– Correct adjustment data

S025

Bad lineariza-

tion table

– Bad linearization table

– Carry out linearization

S038

Slave outside

the specifica-

tion

– Slave outside the specifica-

tion

– Check Slave

S125

Ambient tem-

perature too

high/too low

– Ambient temperature too

high/too low

– Protect instrument with

isolating material against

extreme temperatures

The instrument has no status messages to the section "Maintenance".

9.3 Rectify faults

The operator of the system is responsible for taking suitable meas-

ures to rectify faults.

The first measures are:

•

Evaluation of fault messages via the indicating and adjustment

module

•

Checking the output signal

•

Treatment of measurement errors

Further comprehensive diagnosis possibilities are offered by a PC

with the software PACTware and suitable DTM.

In many case, the failure reasons can thus be determined and faults

rectified.

The following table describes possible errors with the output signal

and helps to remove them:

Error

Cause

Rectification

Output signal not stable

Level fluctuations

Set damping according to the instrument via

the display and adjustment module or PACT-

ware/DTM

Output signal missing

Electrical connection faulty

Check connection according to chapter

"Connection steps" and if necessary, correct ac-

cording to chapter "Wiring plan"

Voltage supply missing

Check cables for breaks; repair if necessary

Operating voltage too low

Check, adapt if necessary

Maintenance

Reaction when malfunc-

tions occur

Procedure for fault recti-

fication

Check output signal

(level measurement)