VEGA MINITRAC 31 Profibus PA User Manual

Page 48

48

6 Set up with the display and adjustment module

MINITRAC 31 • Profibus PA

43836-EN-131119

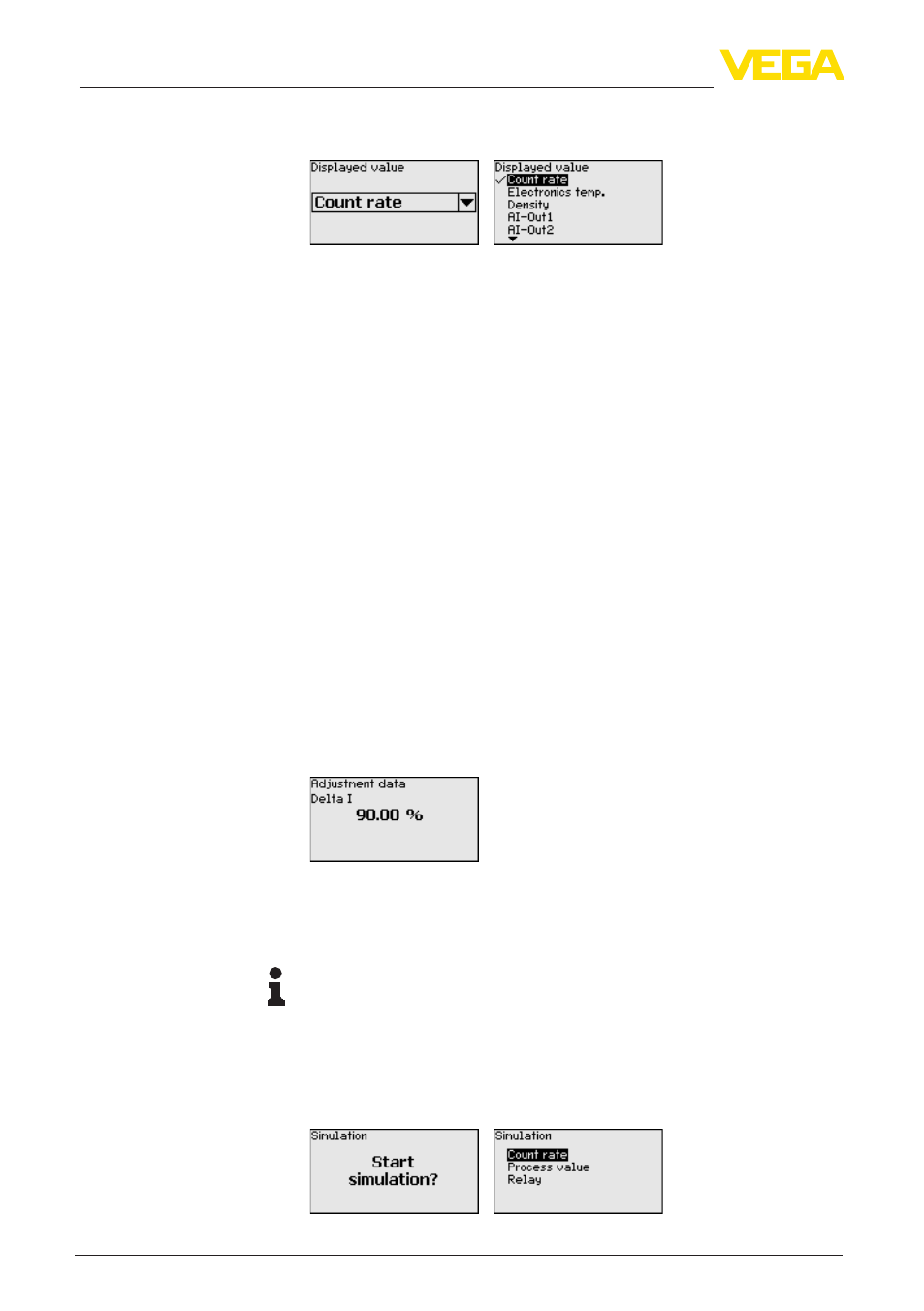

You can choose if the display should show the actual pulse rate, the

electronics temperature or the percentage value.

Diagnostics

In this menu item, you can enquire the status of your sensor. In normal

operation, the sensor displays the message "OK". In case of fault, you

will find the corresponding fault code here.

This parameter is described in the operating instructions manual

"Display and adjustment module".

The peak value function holds the max. and min. values during opera-

tion.

This parameter is described in the operating instructions manual

"Display and adjustment module".

Here you can retrieve the adjustment value of the sensor. This is the

percentage value of the difference of the min. and max. adjustment

points (Delta I). The value is an indication for the reliability and repro-

ducibility of the measurement.

The higher the difference between the two adjustment points,

the higher the differential value (Delta I) and the more reliable the

measurement. A Delta I value below 10 % is an indication for a critical

measurement.

To increase the Delta I value, you have to increase the distance of the

min. and max. adjustment points in the linearization.

In this menu item you can simulate measured values via the current

output. This allows the signal path to be tested, e.g. through down-

stream indicating instruments or the input card of the control system.

Note:

To carry out a simulation with the display and adjustment module,

you have to switch on the simulation switch on the electronics module

(switch position 1).

You can find the rotary switch on the electronics module in the elec-

tronics and connection department (large cover).

You can simulate different values:

Diagnostics - Device

status

Diagnosis - Peak value

Diagnosis - Adjustment

data

Diagnosis - Simulation