7 parameter adjustment - real value correction – VEGA MINITRAC 31 Profibus PA User Manual

Page 64

64

6 Set up with the display and adjustment module

MINITRAC 31 • Profibus PA

43836-EN-131119

With this menu item you safeguard the sensor parameters against

unauthorized or unintentional modifications.

This menu item is described in the operating instructions manual

"Display and adjustment module".

6.7 Parameter adjustment - Real value correction

To correct a level measurement, a real value correction can be carried

out when a certain level is reached. This is for example necessary in

case of recurring buildup on the vessel wall.

The level measurement can thus be reset to the correct real value.

The level measuring instrument acts as Master and the MINITRAC 31

operates as Slave.

First of all, define the function of the Slave instrument before you

define the Master instrument. The Master instrument can thus imme-

diately recognize the connected Slave.

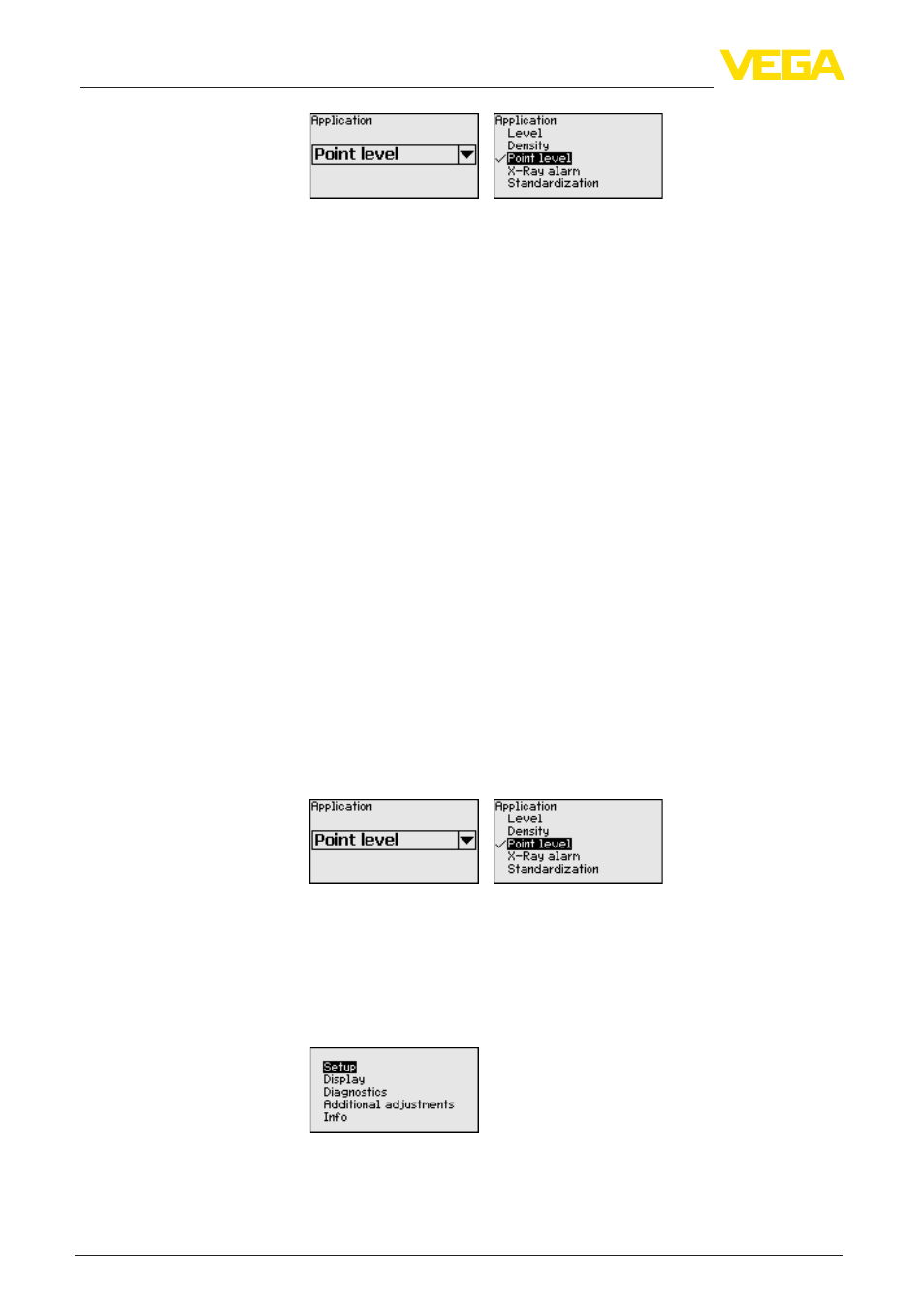

For this purpose, the Slave instrument must be defined as "Real value

correction". Select under the menu item "Setup/Application" the func-

tion "Real value correction".

You can set the address (MGC) on the Slave instrument at will. Only

the address "0 - 0" is reserved for the Master instrument.

The Master instrument must have the function "Level". For this

purpose, select under the menu item "Setup/Application" the function

"Level".

Set the address setting (MGC) on the Master instrument to "0 - 0".

You have to enter the address of the Slave instrument in the list of

the Master instrument. This function is not possible in the display and

adjustment module. To do this you need PACTware with the respective

DTM.

The main menu is divided into five sections with the following func-

tions:

Setup: Settings, e.g. for measurement loop name, isotope, applica-

tion, background radiation, adjustment, signal output

Display: Settings, for example language, measured value display

Lock setup - adjustment

Real value correction

Main menu