VEGA MINITRAC 31 Profibus PA User Manual

Page 34

34

6 Set up with the display and adjustment module

MINITRAC 31 • Profibus PA

43836-EN-131119

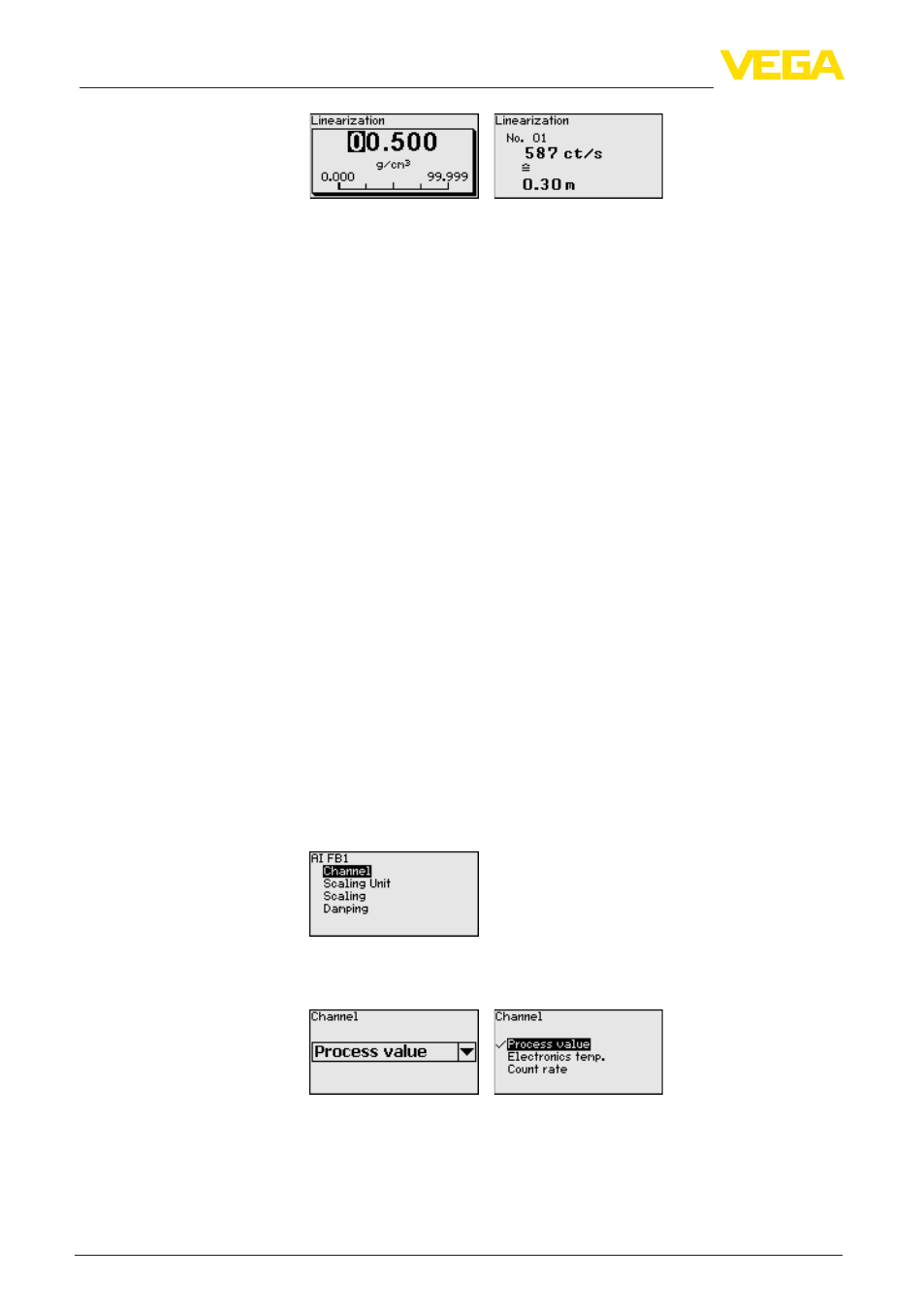

Accept the value pair with "OK".

Depending if you have started with full or empty vessel, you have to

continue emptying or filling the vessel.

Also carry out such a linearization with several different filling heights

if you have a linear vessel.

A maximum of 32 linearisation points is possible.

In this menu item you can adjust the damping of the sensor. With

it you can suppress fluctuations in the measured value indication,

caused e.g. by an agitated product surface. This time can be between

1 and 1200 seconds. Keep in mind that the reaction time also in-

creases and the instrument reacts to quick level changes with a delay.

Generally a time of approximately 60 seconds is sufficient to smooth

the measured value indication.

Radiation from external sources can influence the measuring result of

the sensor.

Possible external radiation sources can be, for example, a weld joint

test on a neighbouring facility or other radiation-based instruments.

An X-ray alarm is triggered if the impulses (ct/s) are more than 25 %

above the max. value from the linearization table.

This fault message is only outputted for the period of the increased

X-ray radiation. Then the fault message is automatically reset.

In this menu item you can determine the behaviour of the sensor

when external radiation sources appear.

Since the adjustment is very comprehensive, the menu points of

Function Blocks 1 (FB1) were put together in a submenu.

In menu item"Channel" you determine which measured value the

output refers to.

In menu item "Scaling unit" you define the scaling variable and the

scaling unit for the pulse rate on the display, e.g. volume in percent.

Setup - Damping

Setup - External radiation

alarm

Setup - AI FB1

Setup - AI FB1 - Channel

Setup - AI FB1 - Scaling

unit