VEGA VEGASCAN 850 User Manual

Page 86

86

VEGASCAN 850

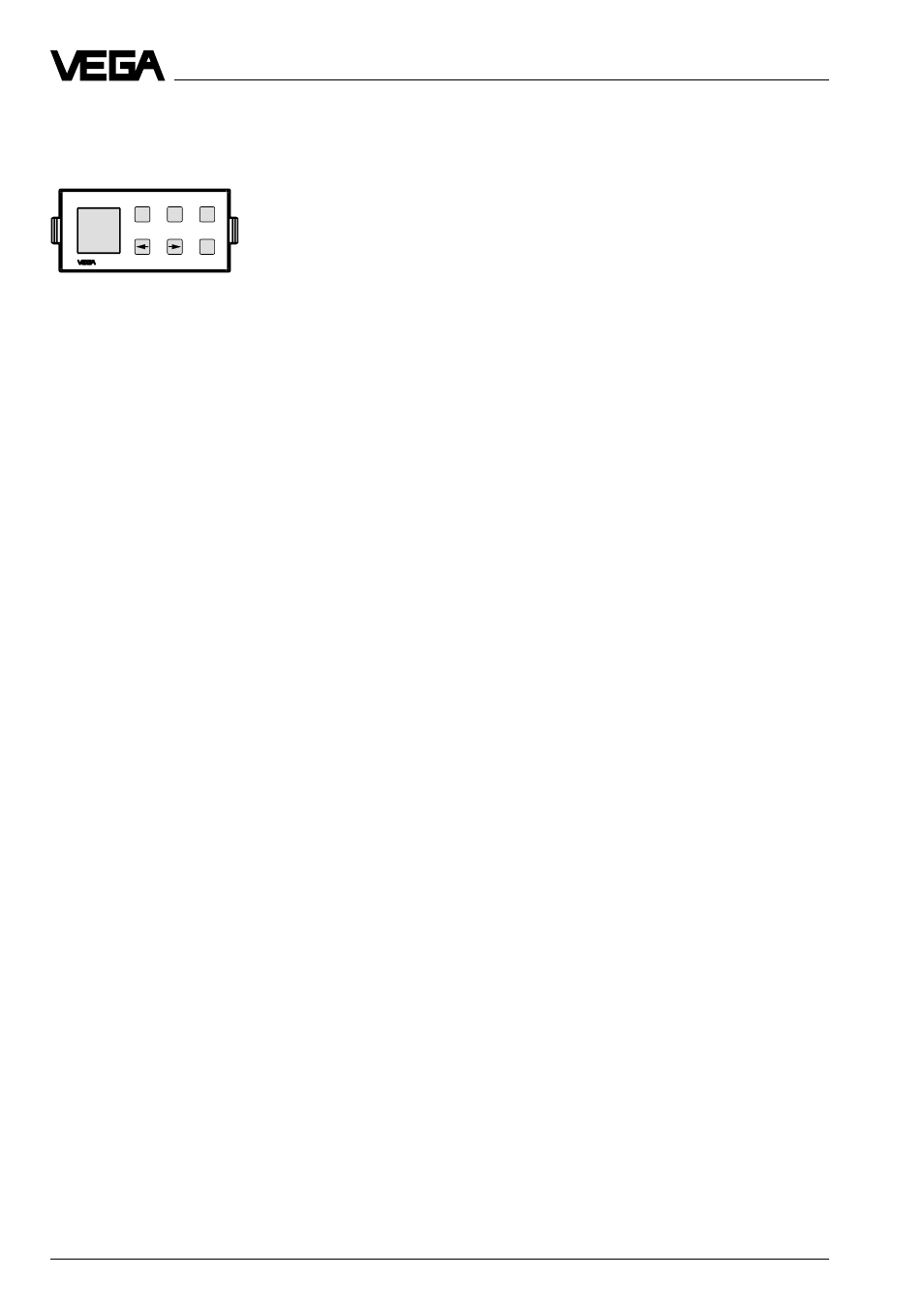

Setup - Sensor adjustment with the adjustment module MINICOM

6.3 Sensor adjustment with the ad-

justment module MINICOM

-

+

ESC

OK

Tank 1

m (d)

12.345

Beside the PC, the ultrasonic sensors VE-

GASON 51V … 56V can also be adjusted

with the small, detachable adjustment module

MINICOM in the sensor.

Only the sensor-relevant adjustments such

as e.g. scaling of the sensor display, operat-

ing range, meas. conditions, sensor display

scaling or false echo storage are possible

with the adjustment module MINICOM. Not

possible are all adjustment steps relating to

the configuration, the conditioning and the

signal processing (configuration of the inputs

and outputs, linearisation curves, simulation

…). This is only possible with the PC directly

on VEGASCAN 850.

You carry out all adjustment steps with the 6

keys of the adjustment module. A small dis-

play shows you, apart from the measured

value, a short message on the menu item or

on the value of a menu adjustment.

The information volume of the small display,

however, cannot be compared with that of the

adjustment program VVO, but you will soon

get used to it and will be able to carry out

your adjustments quickly and directly with

the small MINICOM (see menu plan on the

following pages).

1.

Measurement in gases

2.

Operating range

3.

Meas. conditions

4.

False echo storage (only necessary, if

failures occur during operation).

5.

Indication of the useful and noise level

6.

Processing/Scaling of the sensor display

In the following you will find the sensor-spe-

cific setup items 1 … 6.

1. Measurement in gases

Adjustment is only necessary when the

measurement is made in gases (Co

2

, He,

etc.) deviating from air. In case of measure-

ment in gases, sound the distance of the

sensor to the product surface and enter it in

the menu item "Measurement in gases“. The

sensor can then take the modified sonic

velocity in gases (as opposed to air) and

output correct levels.

2. Operating range

Without special adjustment, the operating

range corresponds to the measuring range.

The measuring range has already been ad-

justed with the min./max. adjustment. Gener-

ally it is useful to choose a slightly bigger

(approx. 5 %) operating range than the

measuring range.

Example:

Min./max. adjustment: 0.500 … 3.500 m;

adjust operating range to approx.

0.400 … 3.600 m.