VEGA VEGASCAN 850 User Manual

Page 80

80

VEGASCAN 850

The sensor then outputs the actual filling

volume by means of the adjusted vessel

dimensions.

• Quit the menu with

"OK.

• Confirm with

"OK and your individual lin-

earisation curve is saved in the sensor.

Again in the menu window "

Conditioning“, you

can enter with the menu item "

Integration

time“ a measured value integration. This is

recommended for agitated product surfaces,

to prevent the measured value indication and

output from changing constantly.

As a standard feature, an integration time of

0 seconds is preset.

• Quit the menu with

"OK., you are again in

the menu window "

Instrument data param-

eter adjustment“.

• Quit the menu window with

"OK.

Setup - Adjustment with the PC

There is a linear interpolation between the

linearisation points.

• Click to

"OK and you are again in the

menu window "

Tank calculation“.

• Again click in the menu window "

Tank cal-

culation“ to

"OK and you are in the lineari-

sation menu.

Here the calculated linearisation curve is

again outputted. The volume information

under "

Linearised“ now corresponds no

longer to the calculated volume of the tank

calculation program. Why?

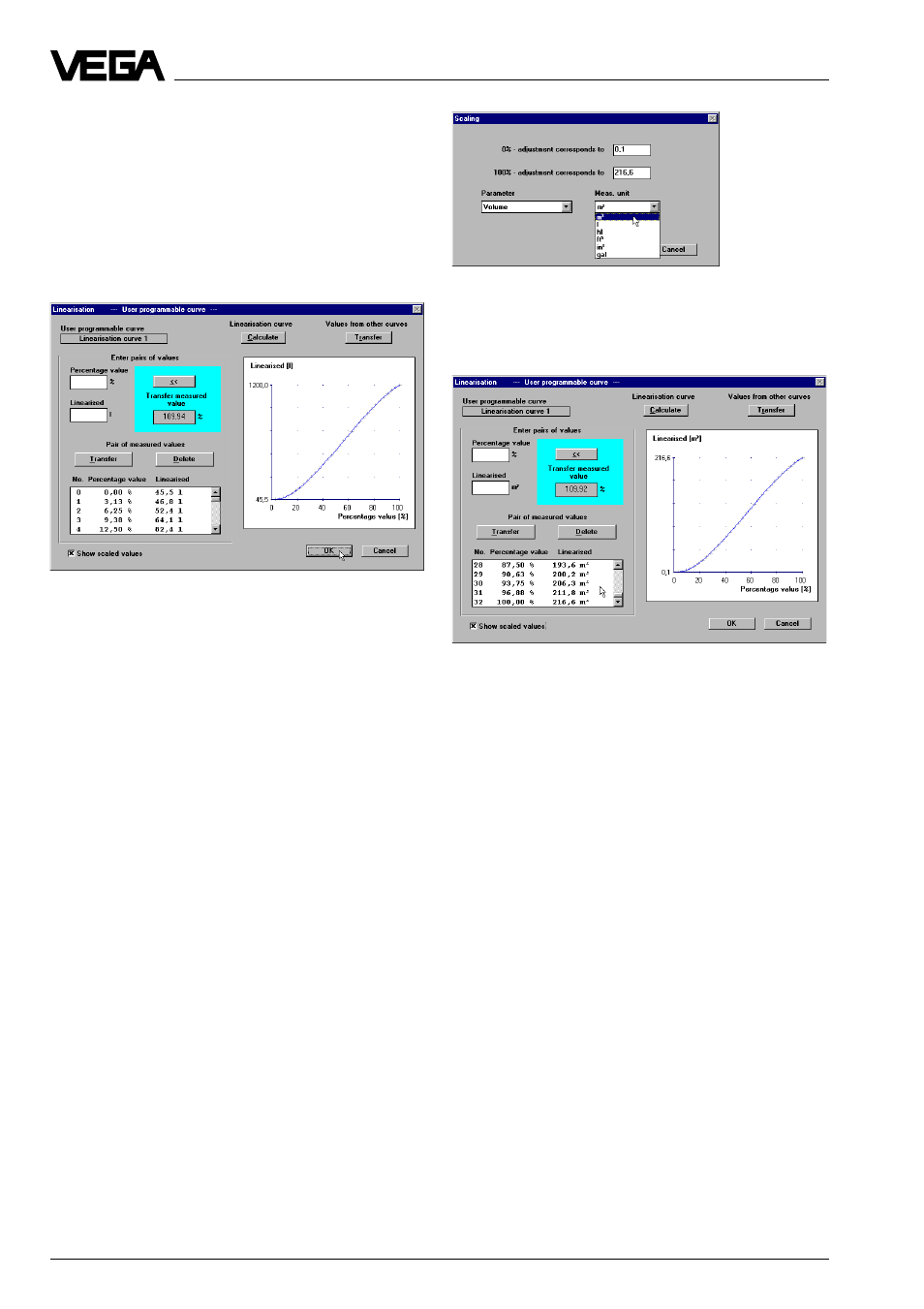

In the menu "

Scaling“ (Instrument data/Condi-

tioning/Scaling) you entered that at 0 % filling

there are 45 liters in the tank and at 100 %

filling 1200 liters. The geometry of the calcu-

lated cylindrical tank is reduced to a size that

has a volume of only 1200 liters. The lineari-

sation curve of the calculated vessel is there-

fore modified to fit the volume data you

entered in the menu "

Scaling“.

If the true content of the calculated vessel

should be outputted, the volume that was

determined in the tank calculation program

must be entered in the menu "Scaling“.