Measurement set-up for gases – VEGA VEGADIF 34 … 51 User Manual

Page 56

56

VEGADIF 34 … 51

20094-EN-030731

Installation connections

Instructions for both connections

- For steam flow measurements, blow down

lines should be installed. The line to the blow

down valve should be as straight as possi-

ble.

- The impulse lines must be able to dissipate

condensation heat. Hence they should not

be insulated.

- VDE/VDI regulation 3512 or different DIN

standards give additional information.

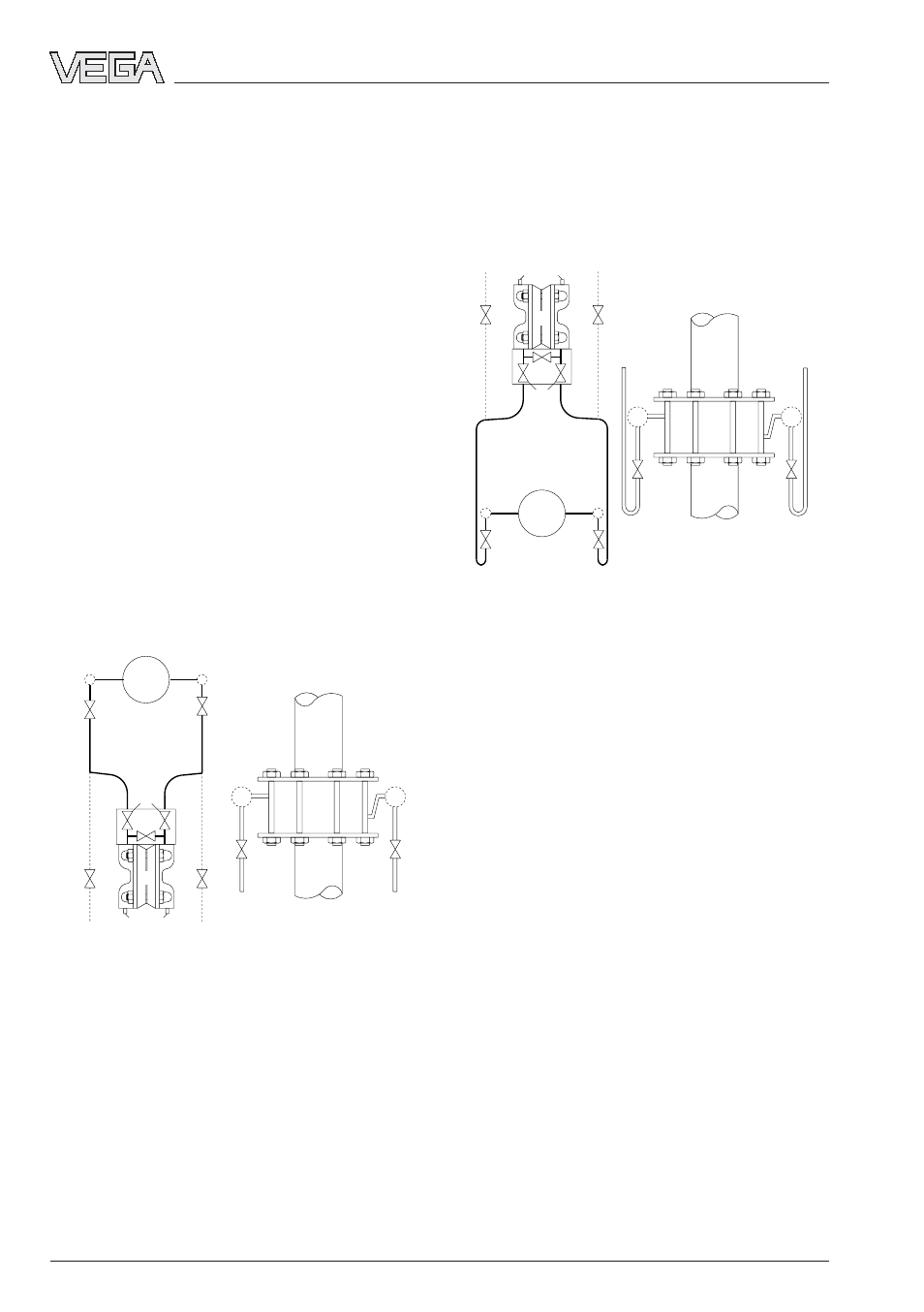

Measurement set-up for gases

Humid gases at ambient temperatures contain

a certain quantity of condensating particles.

The recommended installation position of the

transmitter is hence above the pressure tap-

ping points so that condensate can return to

the process. The arrangement prevents un-

equal condensate buildup in front of the plus

and minus side of the transmitter and the

resulting measurement errors. The impulse

lines must be run with sufficient gradient.

5

5

2

1

6

6

7

6

8

8

8

8

6

-

+

4

3

1 Inlet valve

2 Equalization valve

3 Transmitter

4 Vent or drain valve

5 Blow down valve (if needed)

6 Block valve

7 Effective pressure transmitter

8 Adjustment pots

With dry gases, the transmitter can be in-

stalled above as well as below the pressure

tapping points. Also in this case, the impulse

lines must be run with sufficient gradient so

that condensate can flow to the drainage

valves.

1 Inlet valve

2 Equalization valve

3 Transmitter

4 Vent or drain valve

5 Blow down valve (if needed)

6 Block valve

7 Effective pressure transmitter

8 Adjustment pots

Instructions for corrosive gases

If the measuring cell needs to be protected

against very corrosive gases, an arrangement

with protective vessels acc. to VDE/VDI 3512

should be implemented. As an alternative, the

method of protective gas flushing can be

implemented - it is applicable for corrosive

gases with impurities.

5

5

2

1

6

6

7

6

8

8

8

8

6

-

+

4

3