Vegadif 34, 35, Installation on closed vessels – VEGA VEGADIF 34 … 51 User Manual

Page 48

48

VEGADIF 34 … 51

20094-EN-030731

VEGADIF 34, 35

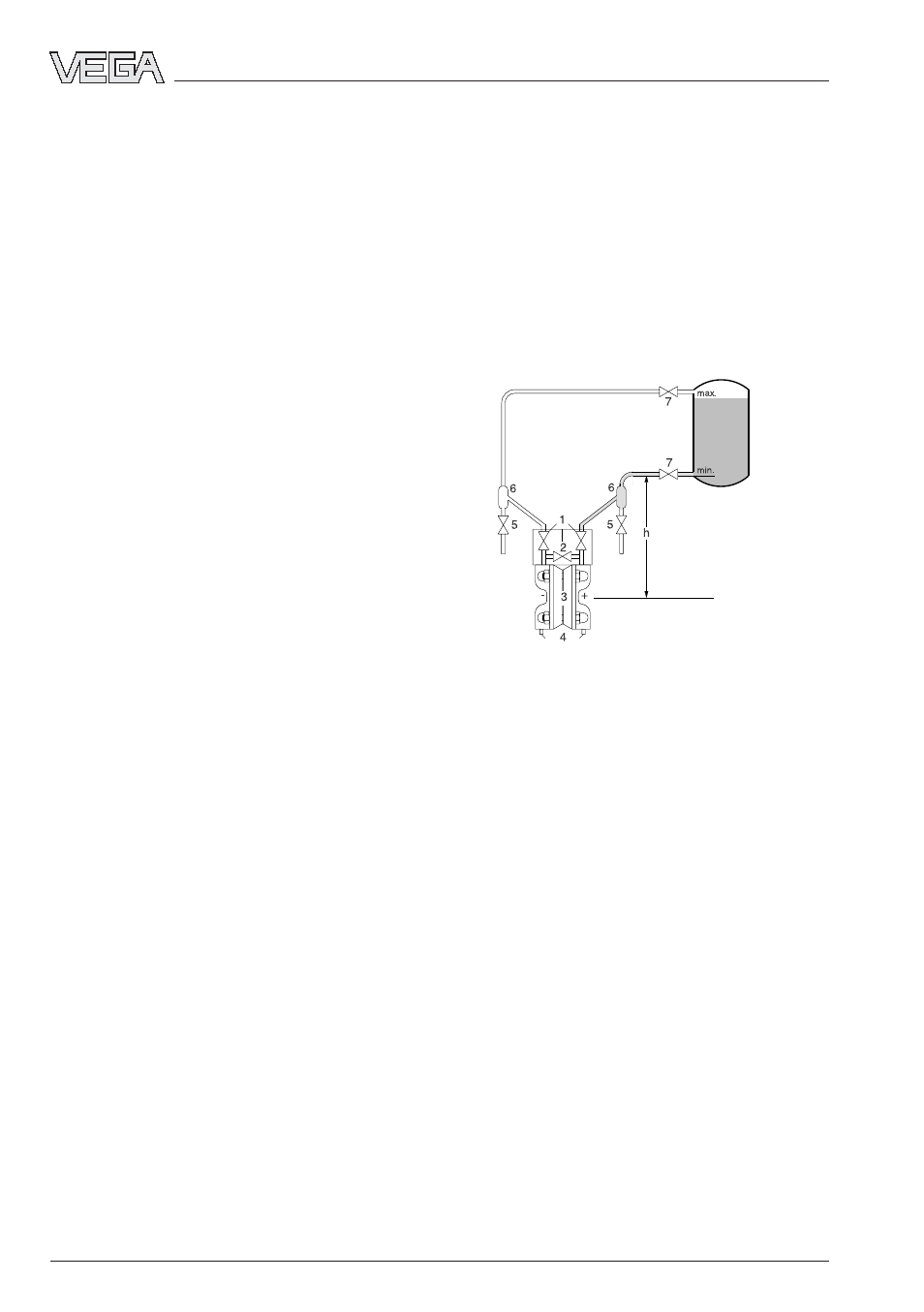

Standard installation connection

The transmitter should be installed preferably

at the height of the planned pressure tapping

point. If a location below the lower pressure

tapping point is planned, the height difference

„h“ (to the centre of the measuring cell) be

taken into account in the adjustment of zero

and span.

1 Inlet valves

2 Equalization valves

3 Transmitter

4 Vent or drain valves

5 Blow down valves

6 Separator for impurities

7 Block valves

Note:

- Unlike single pressure transmitters differen-

tial pressure transmitters are selected only

according to the expected pressure differ-

ence. As long as the overlaid pressure

does not exceed the permissible nominal

pressure, it does not have to be taken into

account. The selected measuring range can

thus be perfectly adapted to the expected

pressure difference.

- The described connections are recom-

mended measurement set-ups. For other

measurement set-ups, various VDE/VDI

regulations or DIN standards (e.g. VDE/VDI

3512) provide further installation instruc-

tions.

Installation connections

This installation has the advantage that zero

and span can be checked/modified without

emptying the vessel. Valve 3 enables the

necessary venting/emptying of the tapping

socket.

Installation on closed vessels

In a closed, pressurised vessel, the level of

the medium is determined by measuring the

hydrostatic pressure. The sum of the liquid

hydrostatic pressure and the overlaid pres-

sure is the total pressure acting on the bottom

of the vessel. The hydrostatic pressure is

therefore the difference between the total

pressure and the overlaid pressure.

The hydrostatic pressure corresponds to the

level of the product, measured from the centre

of the flange isolating diaphragm, multiplied by

the specific gravity of the product (because

the overlaid pressure acts on the plus side as

well as on the minus side of the transmitter, it is

compensated in differential pressure genera-

tion).

∆

p =

ρ

• g • h

∆

p: hydrostatic pressure [N/m

2

]

ρ

:

density of the fill fluid [kg/m

3

]

g:

acceleration due to gravity [m/sec

2

]

h:

level [m]

With this installation a blow down valve and a

separator for impurities are recommended for

the impulse line. This measure is not neces-

sary if the medium is clean and the formation

of buildup or sludge in the pipelines is not

expected.