3 differential pressure measurement, Installation connection for liquids – VEGA VEGADIF 34 … 51 User Manual

Page 44

44

VEGADIF 34 … 51

20094-EN-030731

Installation connections

Connection of the transmitter to the valve

block

The connection of the transmitter is normally

made just before commissioning. Generally

seal rings made of PTFE as well as four

screws are supplied with the valve block. Flat

seals are used on both process connections

of VEGADIF.

Procedure:

1 Push both seal rings into the grooves of the

valve block (it is always recommended that

two new PTFE seals be used every time the

transmitter is connected to the valve block).

2 Screw the transmitter carefully onto the

valve block (4 screws).

3 Tighten the screws crosswise (recom-

mended torque 6 - 8 Nm).

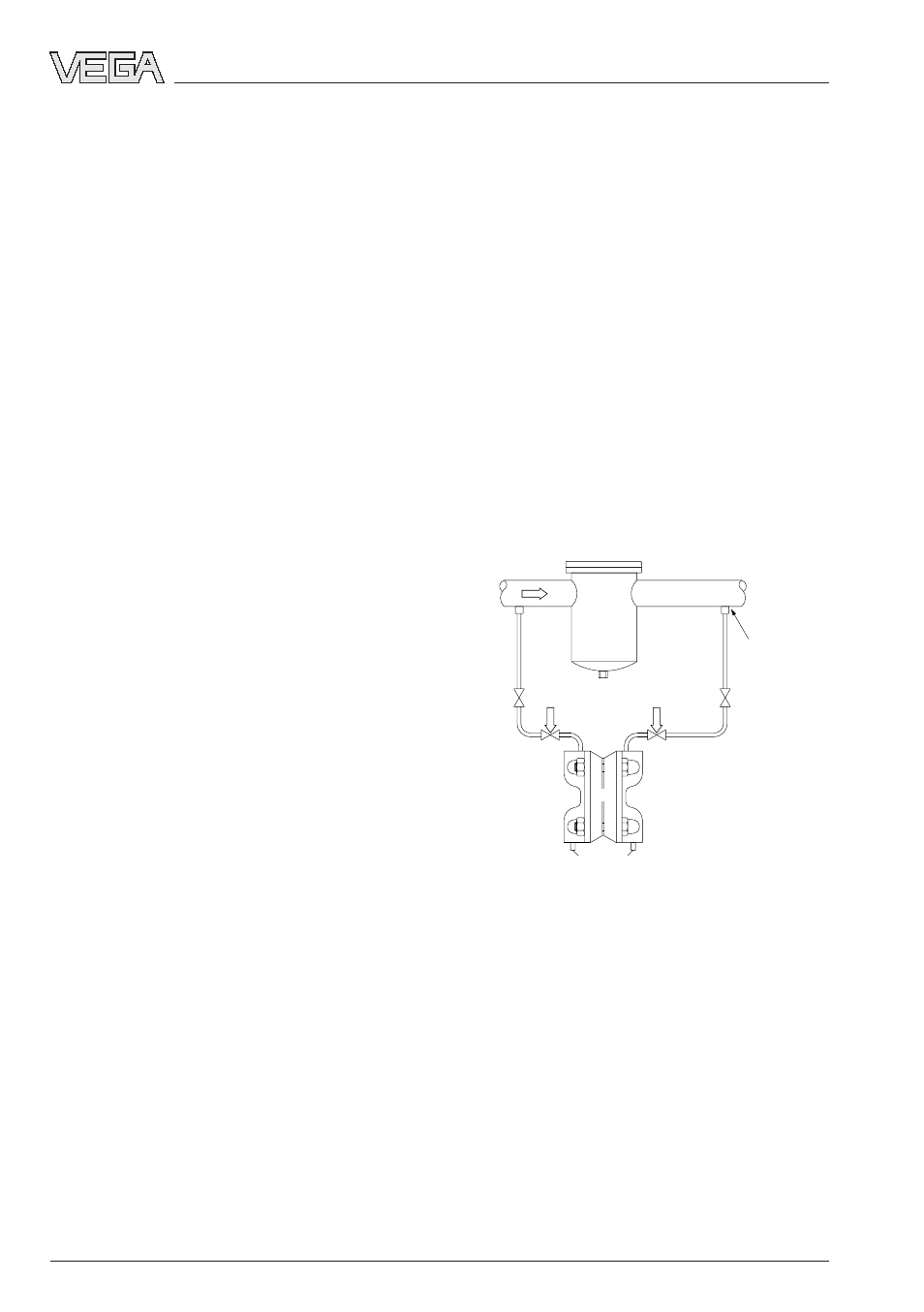

1 Inlet valves

2 Transmitter

3 Vent or drain valves

4 Block valves

5 Pressure tapping point

6 Ventilation screw

For differential pressure measurements refer-

enced to the open atmosphere, the impulse

line must be connected to the plus side of the

transmitter. The minus side remains open to

the atmosphere. In case of extremely dirty

atmospheres, we recommend using a filter on

the minus side or an open tube bent down.

This protects the minus side against buildup.

4

4

1

1

5

6

6

+

-

3

2

5.3 Differential pressure

measurement

Installation connection for liquids

If the pressure of a flowing material is to be

measured in a pipe, the pressure tapping

points must be located where there is steady

flow. The impulse lines must be installed with

continuous gradient

≥

1 : 10 (i.e. 10 cm per

meter).

The recommended installation position of the

transmitter is below the pressure tapping

points.

With products containing solid particles, the

pressure tapping points must be positioned

on top of the pipelines.