Installation connections – VEGA VEGADIF 34 … 51 User Manual

Page 51

VEGADIF 34 … 51

51

20094-EN-030731

The following must be noted:

- The impulse line from the adjustment pot to

the vessel must be run with a slight gradient

to the vessel; excess condensate returns to

the vessel, the level in the adjustment pot

remains constant.

- Block valve „2“ between vessel and adjust-

ment pot must not impede the steam line to

the adjustment pot; the installation must

prevent water pockets from forming in the

valve.

- If there is insufficient condensate formation

in the adjustment pot, additional liquid must

be added in small quantities via dosing

valve „6“.

- If the reference liquid has a different density

than the condensate column (1.0 g/cm

3

),

this has to be taken into account for the

span adjustment.

For this installation, a blow down valve and a

separator for impurities are recommended.

This measure is not necessary if the medium

is clean and the formation of buildup or sludge

in the pipelines is not expected.

Note:

For this installation connection, a measuring

cell which allows a lowering of the zero point

down to -100 % (of measuring range) must be

implemented.

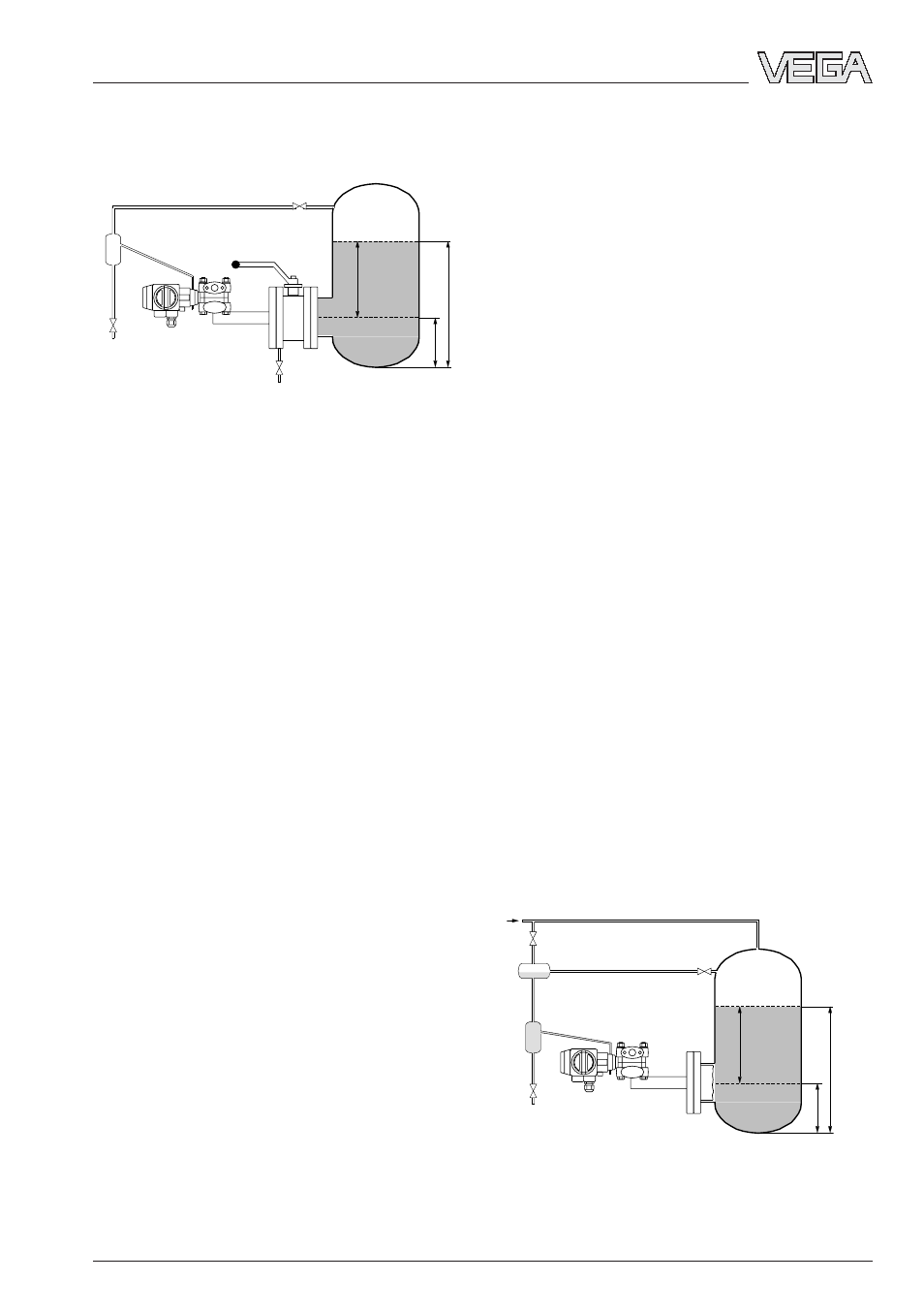

Example VEGADIF 45:

Transmitter directly flanged

1)

1 Transmitter

2 Block valve

3 Adjustment pot

4 Separator for impurities

5 Blow down valve

6 Dosing valve

7 Vent or drain valve

2

4

5

7

3

6

1

h

1

h

2

∆

p

h = ––––––

ρ

• g

Installation connections

1 Transmitter

2 Block valve

3 Separator for impurities

4 Blow down valve

5 Emptying valve

This arrangement has the advantage that zero

and span can be checked (modified) without

emptying the vessel. The valves 5 and 6 allow

the necessary venting/emptying of the tap-

ping socket.

Installation on closed vessels with overlaid

steam pressure

In a closed vessel with steam pressure, the

product level is determined via the measure-

ment of the hydrostatic pressure. The sum of

the steam pressure and hydrostatic pressure

acts as total pressure on the bottom of the

vessel. The hydrostatic pressure is therefore

the difference between total pressure and

overlaid steam pressure.

The transmitter receives the total pressure on

the plus side via the isolating diaphragm, the

overlaid pressure on the minus side via the

impulse line and the process fitting. In a sepa-

rate adjustment pot, a fixed level is generated

by existing condensate. This condensate

column transmits the steam pressure to the

minus side of the transmitter and protects the

measuring cell against hot steam.

2

3

4

1

5

Example VEGADIF 45:

Transmitter flange via maintenance unit

h

1

h

2

∆

p

h = ––––––

ρ

• g