Vegadif 51 – VEGA VEGADIF 34 … 51 User Manual

Page 52

52

VEGADIF 34 … 51

20094-EN-030731

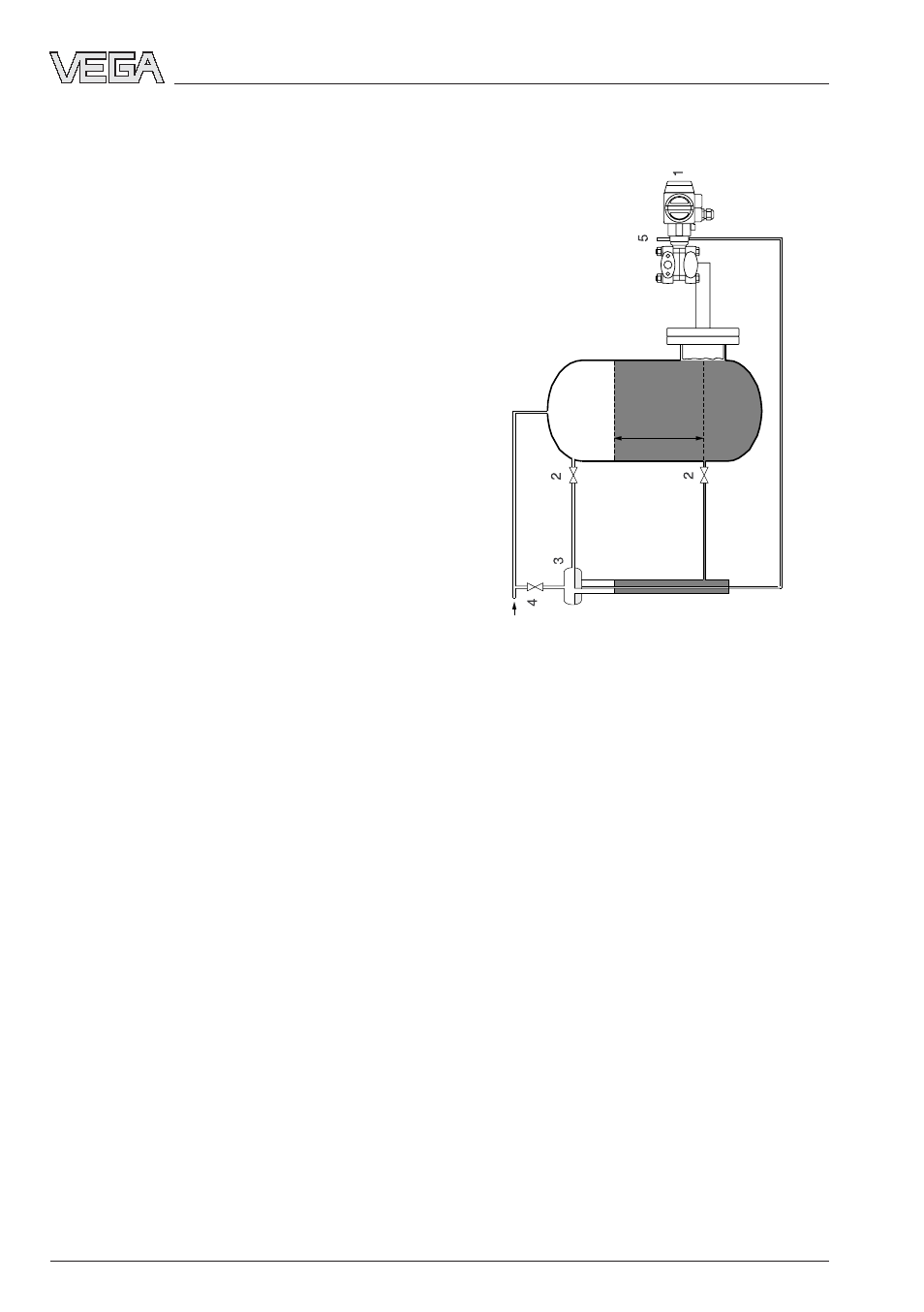

1 Transmitter

2 Block valve

3 Adjustment pot

4 Dosing valve

5 Vent or drain valve

VEGADIF 51

Installation on closed vessels with overlaid

pressure

In a closed, pressurised vessel, the level of a

product is determined by measuring the hy-

drostatic pressure. The sum of the hydro-

static pressure and the overlaid pressure acts

as total pressure on the bottom. The hydro-

static pressure is therefore the difference

between total pressure and overlaid pressure.

The transmitter receives the total pressure on

the plus side via the isolating diaphragm and

the overlaid pressure on the minus side.

The isolating diaphragm must be mounted on

the vessel in such a way that the isolating

diaphragm is completely covered by the

product even at min. level.

Example VEGADIF 45:

Transmitter directly flanged

∆

p

h = ––––––

ρ

• g

Installation connections

The differential pressure is determined by the

transmitter as follows:

∆

P

= p

F

+ p

D

– (p

k

+ p

D

)

∆

P

= p

F

– p

k

∆

P

: Differential pressure

p

F

: Hydrostatic pressure of the liquid column

p

D

: Static pressure of the steam

p

k

: Hydrostatic pressure of the condensate column

(constant)

Zero is determined to a negative differential

pressure p

F

– p

k

.

Installation on closed vessels with overlaid

steam pressure and heated comparative

column

This installation is a variant of the one de-

scribed previously. In this case, the conden-

sate column is covered by a tube (of larger

nominal diameter) which is filled with the meas-

ured product and acts a communicating pipe.

Through the resulting temperature equalisa-

tion, the density is the same in both columns.

The outer pipe must therefore be insulated -

not the adjustment vessel however (the con-

densate heat must be dissipated).

This arrangement is preferred for measuring

substances with higher density because it

delivers more accurate measurement results.

The previously described technical conditions

also apply to this measurement set-up.

1)

Der Messumformer kann entsprechend den

vorhergehenden Darstellungen auch über eine

Wartungseinheit angeflanscht werden.