Installation guide, Installation – Veris Industries H8053 Install User Manual

Page 3

H8051/H8053

Z201659-0N

PAGE 3

©2011 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

12112

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

INSTALLATION GUIDE

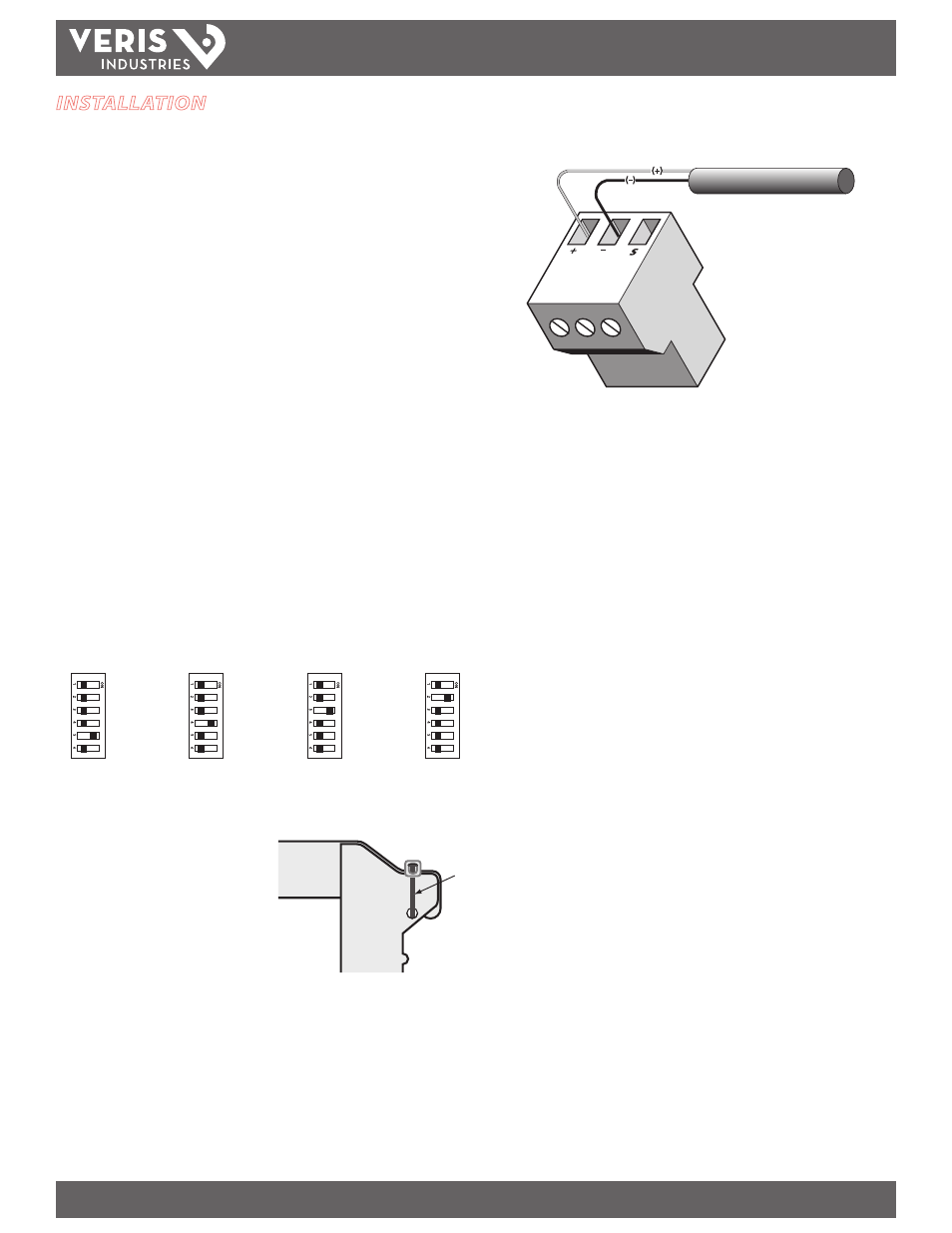

4. Attach the pulse output wires as shown. Observe (+) and (-) polarity. Insulate any

exposed wiring.

5. Check power reading (these calculations are approximations only).

Expected power:

single-phase kW = Volts x Amps x PF / 1000

3-phase kW = Volts x Amps x 1.732 x PF / 1000

kW = Horsepower x 0.746

Seconds per pulse:

S = kWh pulse setting

seconds/pulse = (3600 x S) / kW

INSTALLATION

Disconnect and lock out power to the enclosure before

installation.

The Enercept meter, including the current transformers (CTs), voltage connection

fuses, and fuse pack, is permitted within electrical distribution equipment

including but not limited to panelboards, switchboards, motor control centers, and

transformers. Carefully review the equipment in which the Enercept meter will

be installed. Consider the following installation conditions during the installation

process:

• Review the equipment enclosure for ventilation openings. Wires will cross

many of these openings in a normal installation; however, do not install

the Enercept where it will substantially block ventilation openings in the

enclosure.

• The Enercept meter and the wiring installed within a wiring space or

gutter should not exceed 75% cross sectional fill at the Enercept meter

parts as addressed in the NEC. Improper installation of Enercept meter in

the wire gutter of equipment may affect the thermal performance of the

equipment.

• Consider the arrangement of CTs within the equipment to ensure

adequate bending radius of conductors.

• Review the arrangement and location of the CTs within the equipment.

Do not create undue strain on the conductor. A CT may require

appropriate support in order to address such a condition.

1. Set the DIP switches for the desired pulse rate as shown. Not all settings are

allowed for each model.

kWh/pulse

0.1 KWH PER PULSE

Not allowed on 1600A

and 2400A models

0.10

0.25

0.50

1.00

kWh/pulse

0.25 KWH PER PULSE

Not allowed on

2400A model

0.10

0.25

0.50

1.00

kWh/pulse

0.50 KWH PER PULSE

All models

0.10

0.25

0.50

1.00

kWh/pulse

1 KWH PER PULSE

All models

0.10

0.25

0.50

1.00

2. Connect the voltage leads to the conductors, at a location that is not normally

turned off. Connect voltage leads on the line side of the conductor to ensure

constant power to the meter. See the

Wiring section.

3. Snap the CT onto the conductor. If the

application can exceed 20 times the

rated CT current, use wire ties to secure

the I-bar to the CT housing. This CT

automatically detects phase reversal, so

CT load orientation is not important.

Wire tie