Installation of inter-axle diff to carrier, Yoke removal & seal replacement, Installation of inter-axle differnetial to carrier – Spicer Tandem Drive Axles Service Manual J340-S, J380-S, J400-S, W460-S User Manual

Page 32: Yoke removal and seal replacement

INSTALLATION OF INTER-AXLE DIFFERNETIAL TO CARRIER

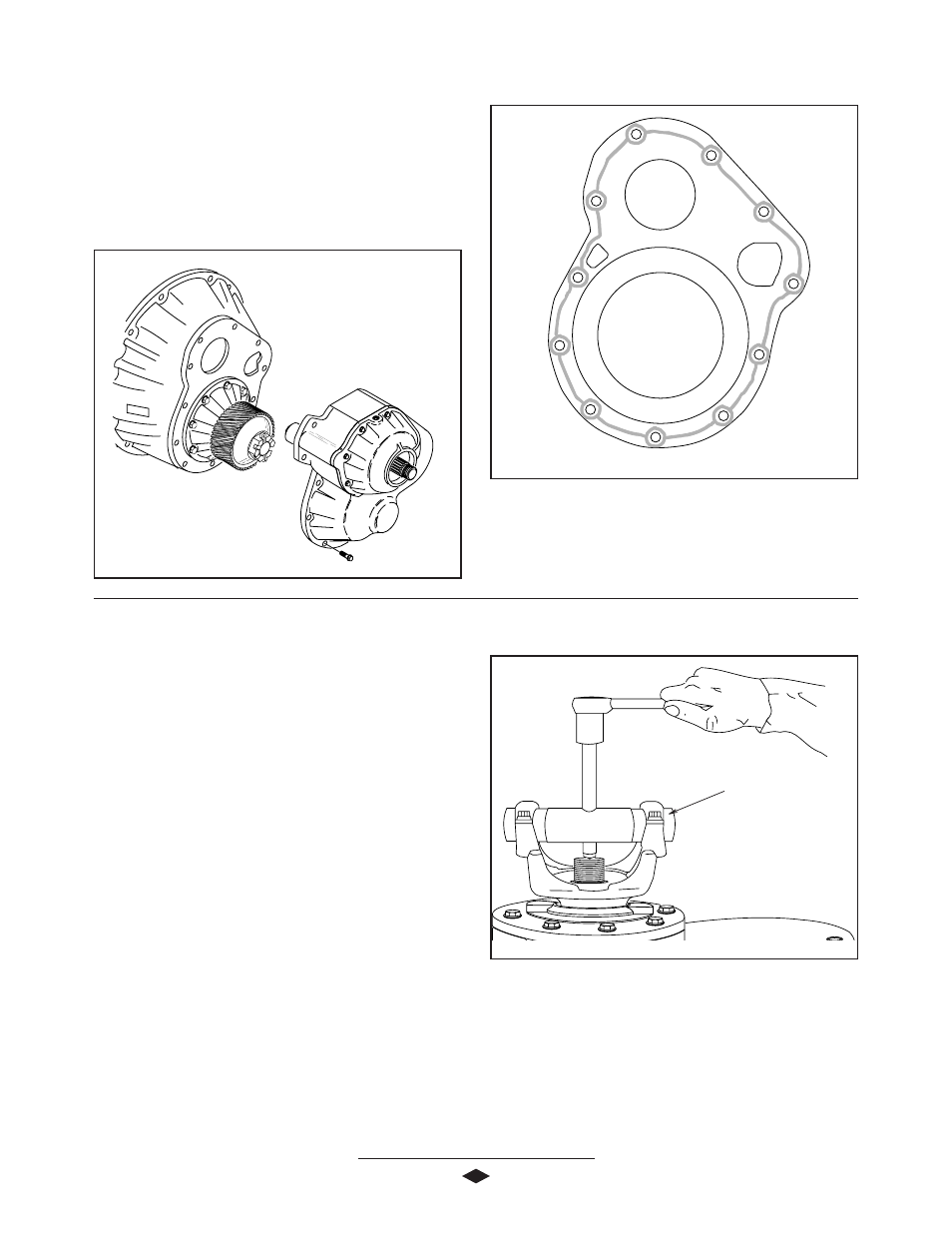

1 . Thoroughly clean mating face of carrier and apply an 1/8

inch bead of Loctite #518 Gasket Eliminator. See Figure

21 for correct bead pattern.

2 . Align inter-axle differential case with carrier housing and

insert bolts and torque to 160-180 Lb-Ft (217-244 N-m).

FFFFFigur

igur

igur

igur

igure 2

e 2

e 2

e 2

e 21

1

1

1

1

#518 Gasket Eliminator Bead Pattern

Yoke Remover

Figure 22

Figure 22

Figure 22

Figure 22

Figure 22

YOKE REMOVAL AND SEAL REPLACEMENT

1 . Disconnect drive shaft at the rear U-joint.

2 . Remove yoke nut.

NOTE: Use of torque multiplier is recommended as torque

specification on input flanged hex nut is 900-1,200 Lb-Ft

(1,220-1,627 N-m).

3 . Remove end yoke using the yoke remover tool. See

Figure 22.

4 . Remove oil seal.

5 . Inspect end yoke seal surface for grooves. If grooves can

be detected with fingernail, it should be repaired with a

CR SPEEDI-SLEEVE

®

or replaced.

6 . Clean and dry threads on input/ouput shaft or

pinion. Install oil seal using proper tools.

7. Install end yoke using yoke installer.

NOTE: Spicer recommends that new flanged hex nuts be used.

8 . Apply Loctite #680 (green) to threads.

9 . Use torque multiplier and torque flanged hex nut to 900-

1,200 Lb-Ft (1,220-1,627 N-m).

Yoke Removal and Seal Replacement Complete

30