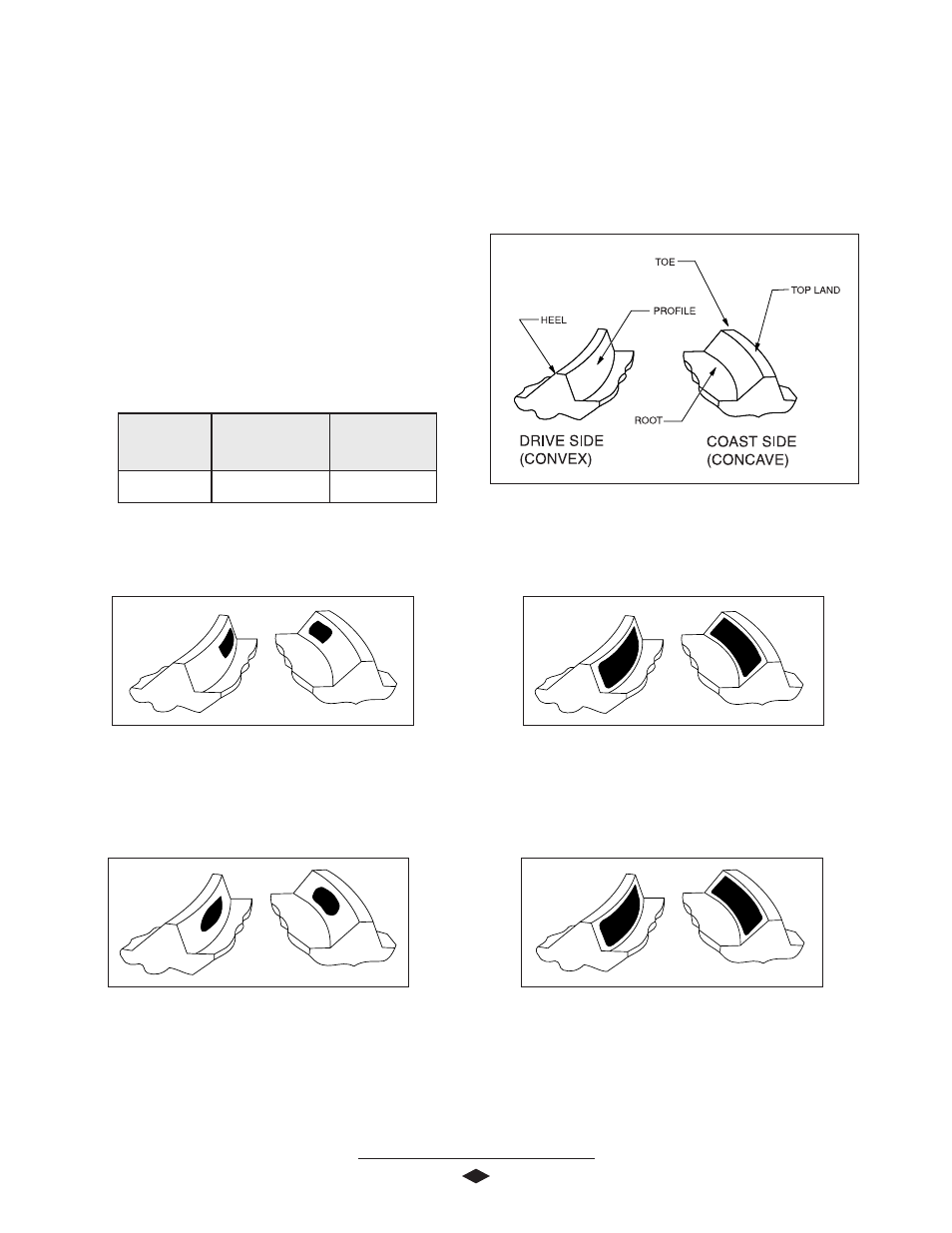

Ring & pinion contact pattern, Ring gear and pinion tooth contact pattern, Correct gear patterns for gleason cut gears – Spicer Tandem Drive Axles Service Manual J340-S, J380-S, J400-S, W460-S User Manual

Page 31: Correct gear patterns for orlikon cut gears

RING GEAR AND PINION TOOTH CONTACT PATTERN

29

CORRECT GEAR PATTERNS FOR GLEASON CUT GEARS

HEAVILY LOADED

LIGHTLY LOADED

The procedures to the right are to be used to establish proper

gear tooth pattern after assembly of the carrier is complete.

NOTE: If matched sets are being reused, measure and record

backlash before disassembly, and reassemble to the same

backlash. This will match ring and pinion gears to the estab-

lished wear patterns. Hand rolled patterns will cover less area

than the gear pattern established by previous service.

Gleason cut gears and Oerlikon cut gears can be identified by

using the following chart.

NOTE: Tooth contact pattern, on this axle model, can be moved only by adjusting backlash. The contact pattern can be moved in

the direction of heel-to-toe, and toe-to-heel; Depth of the pattern cannot be adjusted. If an acceptable tooth contact pattern

cannot be established within limits of backlash, contact Spicer Service at 1-800-666-8688.

CORRECT GEAR PATTERNS FOR ORLIKON CUT GEARS

HEAVILY LOADED

LIGHTLY LOADED

STEP 1. Paint 1/4 ring gear with marking compound on

both the drive and coast side.

STEP 2. Rotate ring gear at least one complete revolution in

both directions while load is being applied.

J Model

W Model

Gleason

047GX1XX

XXXXXXC1

XXXXXXR1

Oerlikon

------

057GX2XX

Example: Gleason cut Wmodel, 584282C1.