Intermediate case assembly – Spicer Tandem Drive Axles Service Manual J340-S, J380-S, J400-S, W460-S User Manual

Page 27

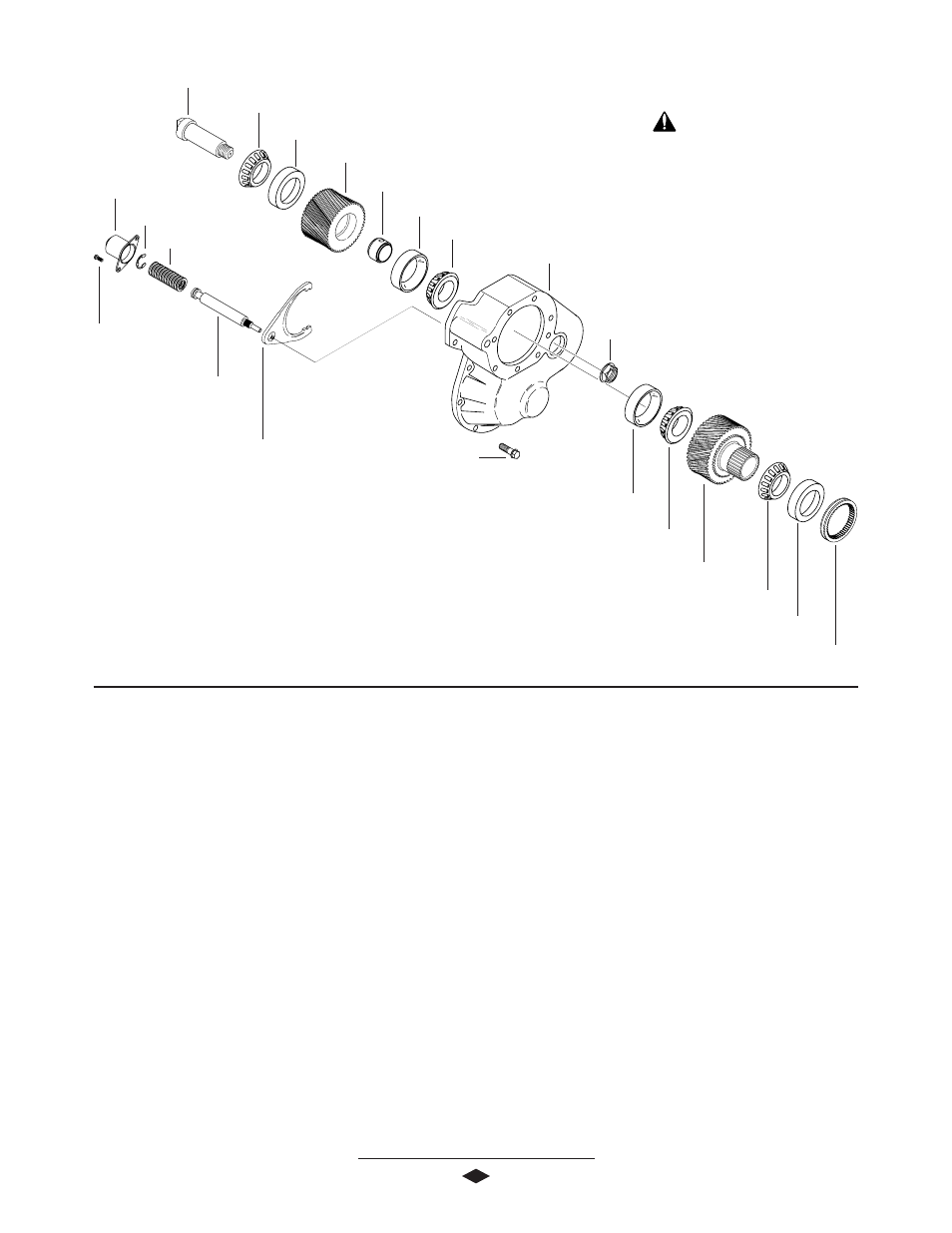

INTERMEDIATE CASE ASSEMBLY

1 . Install bearing cups into the idler gear. Be certain cups

are pressed completely into or improper measurement of

end play will result.

2 . Install bearing spacer and bearings into idler gear. The

end play is controlled by the bearing spacer.

3 . Install idler gear into intermediate case. Slide gear into

position.

4 . Install idler shaft into idler gear and intermediate case.

5 . Install input gear bearing cup into intermediate case. Use

of Loctite to help retain bearing cup in case is recom-

mended.

IMPORTANT: A special plate has been designed to aid in

assembly. A print of the special plate is provided for your

convenience. See Pg. 19.

The plate accomplishes two things:

A. It positions the idler shaft properly to facilitate assembly

of the intermediate case to the differential carrier housing.

B. It retains the input gear bearing cup in the

intermediatecase when checking end play of the inter-axle

differential.

8 . Turn intermediate case over. Install a new prevailing

torque nut.

9. Retain intermediate case to eliminate movement.

Use a torque multiplier wrench and torque idler

shaft nut to 500-600 Lb-Ft (675-800 N-m).

10 .The idler gear is designed to run with end play. Using a

dial indicator, check end play. End play should be .001”

to .006”. If it is not to specification, change bearing

Input Drive Gear

Inter-Axle Differential Bearing Cone

Inter-Axle Differential Bearing Cup

Shift Collar

Shift Fork

Retainer Spring

Retainer Clip

Air Shift Cylinder

Air Shift Cylinder Bolt

(30-40 Lb-Ft)

(41-55 N-m)

Drive Gear Bearing Cone

Drive Gear Bearing Cup

Inter-Axle Differential

Case Bolt

(75 -90 Lb-Ft)

(101-122 N-m)

Idler Gear Front Bearing Cone

Idler Gear Front Bearing Cup

Idler Gear Bearing Spacer (Selective)

Idler Gear

Idler Gear Front Bearing Cone

Idler Gear Front Bearing Cup

Inter-Axle Differential Case

Idler Gear Shaft

Idler Shaft Nut

(500-600 Lb-Ft)

(678-813 N-m)

25

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 33-

34 for W Model torque specifications.

Shift Fork Shaft

(30-38 Lb-Ft)

(41-51 N-m)