Differential assembly – Spicer Tandem Drive Axles Service Manual J340-S, J380-S, J400-S, W460-S User Manual

Page 24

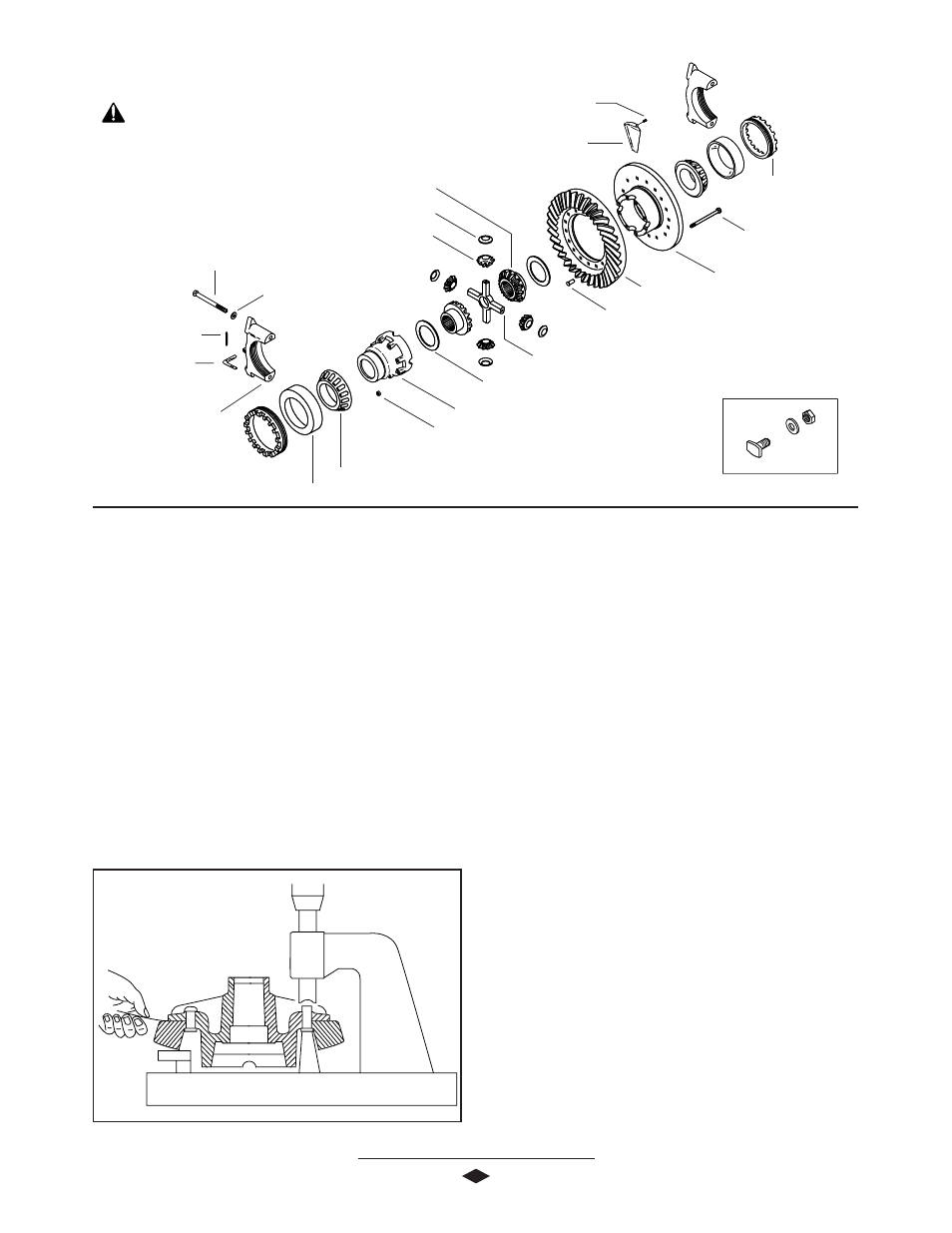

DIFFERENTIAL ASSEMBLY

1 . If ring gear was removed from differential case, reinstall at

this time. Clean mating surfaces and bolt ring gear to

differential case at 3 locations, 120º apart to help

eliminate ring gear runout. Use hydraulic press and

suitable riveting fixture, as shown. Pressure requirement

per rivet is 45-50 tons (41-45 metric tonnes).

The ring gear is properly installed when a .0015” (.038

mm) feeler guage cannot be inserted between the

differential case flange and the ring gear backface. See

Figure 14.

NOTE: Ring gear and pinion must be replaced as a match set

only.

FFFFFigur

igur

igur

igur

igure 1

e 1

e 1

e 1

e 14

4

4

4

4

22

2 . Install bearing cones to differential case halves.

Place bearing cups on cones during remainder of

assembly to prevent damage to bearings.

NOTE: Use of press and proper adapter is required to

eliminate possible damage to bearings.

3 . Apply a small amount of lubricant to all mating surfaces.

This will keep thrust washers in place during assembly and

provide initial lubrication.

4 . Place thrust washer and side gear in flange half of

differential case. Dimples in thrust washers go against

side gear.

5 . Assemble differential pinions and thrust washers on cross

shaft. Place assembly in flange half differential case.

6 . Place remaining side gear and thrust washers in position

on differential pinions.

7. Assemble case halves, making sure that both match marks

are lined up.

8 . Install differential case bolts. Tighten alternately and

evenly. (See Torque Specifications Chart, Pgs. 33-34)

Differential Assembly Complete

Differential Bearing Cup

Cotter Pin

Adjusting Ring

Lock

Differential Bearing

Cap Washer

Differential Case Nut

(160-180 Lb-Ft)

(218-245 N-m)

Differential Case Cap Half

Differential Bearing Cap Bolt

(295-340 Lb-Ft)

(370-435 N-m)

Differential Pinion Mate

Differential Pinion Mate Thrust Washer

Differential Cross Shaft

Differential Side Gear

Ring Gear

Differential Case Flange Half

Adjusting Ring

Differential Bearing Cone

Differential Bearing Cap

Differential Gear Thrust Washer

Ring Gear Rivet

(40-45 tons)

(41-50 metric tonnes)

Oil Scoop

Oil Scoop Bolt

(7-9Lb-Ft)

(9-12 N-m)

Differential Case Bolt

(160-180 Lb-Ft)

(218-245 N-m)

Ring Gear Bolt Kit

(300-320 Lb-Ft)

(406-434 N-m)

(Optional)

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 33-

34 for W Model torque specifications.