Measure and adjust, Replace seal – Spicer Tandem Drive Axles Pro-40 Single Reduction and Single Reduction with Differential Lock User Manual

Page 60

57

60

Forward Assembly

Measure and Adjust

Note: Use bearing cup driver to insure seating of snap ring

after installation with snap ring pliers.

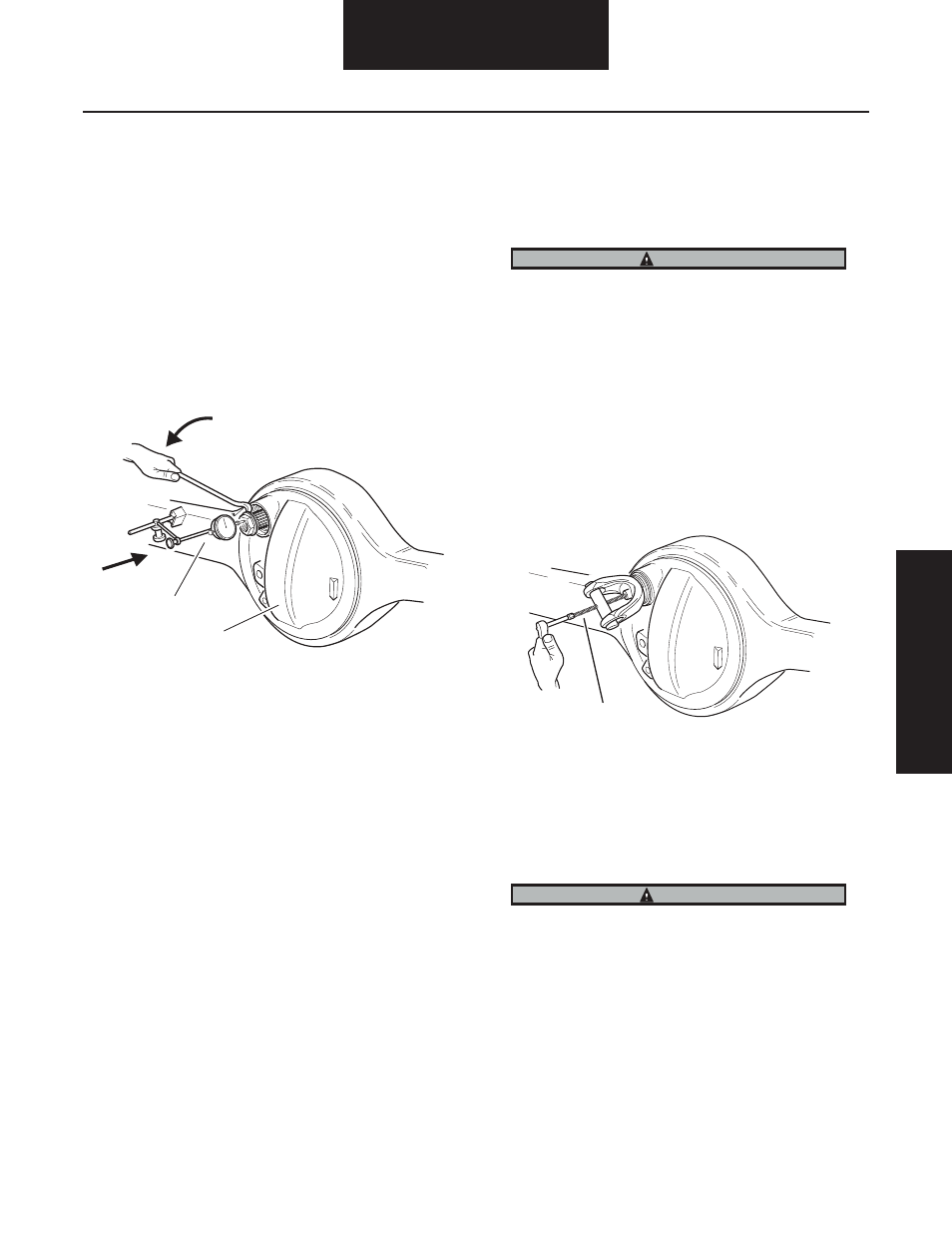

See illustration for steps 1–4.

1. Assemble cover assembly to axle housing.

2. Position dial indicator at yoke end of output shaft.

3. Push in on output shaft and zero the dial indicator.

4. Using a pry bar, move output shaft axially and mea-

sure/record end-play.

Correct end-play for a new assembly is 0.001" to 0.015". The

maximum end-play for a used assembly is no more than

0.015". If end-play is incorrect, contact Dana.

5. Install oil seal. Follow seal replacement procedures

on page 72 of this manual.

6. Install yoke.

7. Install yoke nut. One of the following options may be

utilized:

i.

Install a new nut with the pre-applied thread

adhesive compound. Tighten the nut to the

specified torque 680–832 lbs. ft. (920–1130

N•m).

j.

If a new nut with pre-applied thread adhesive

compound is unavailable, apply “Loctite 277" or

“271” (available in 0.5 ml tube—Dana P/N

129293) to the nut along two threads, for at

least two flats (120°) of the nut midway through

the thickness (See illustration). Tighten the nut

to the specified torque 680–832 lbs. ft. (920–

1130 N•m).

Replace Seal

Dana strongly recommends using seal drivers when installing

new seals. Use the proper driver to make sure that the seal is

square and installed to the proper depth.

Oil seals can be easily damaged prior to installation. Use

care when handling the new seal to prevent damage or con-

tamination. Leave the seal in its package until installation.

On new yokes, leave the protector on the yoke until it is

installed on the shaft to prevent damage or contamination.

1. Inspect axle end-play at the yoke (see page 10). Ser-

vice if beyond specified limit.

2. Remove the old yoke using appropriate tool. A yoke

puller tool may be made from the center section of

most gear puller tools, or may be purchased from

your local tool distributor.

3. Remove seal. Use care when removing the old seal

to prevent damage to the housing seal bore.

4. Inspect the seal bore area for any damage (nicks,

gouges, corrosion). Carefully remove any slight

damage with a crocus cloth. Clean the bore area to

remove any loose debris.

Do not use any silicone or permatex-type bore sealant with

this seal.

5. Remove the new seal from its package and install

with the proper driver:

Service kit #217414

D-Input-Use driver #126917 only

D-Output-Use insert #128706 with driver #126917

R-Pinion-Use driver #126917 only

2

1

3

4

1 - Yoke puller tool

CAUTION

1

CAUTION

Fo

rward Assembly