MSD 2957 Atomic LS Master Early Truck Kit (GEN III 1999-2007) Installation User Manual

Page 12

12

INSTALLATION INSTRUCTIONS

M S D

• W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 5 - 7 1 2 3 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

WARNING: MSD’s Push-Lock fittings are designed

for use with the MSD fuel hose only. Do

not use the MSD fuel hose with other

fittings. Do not use MSD Push-Lock

fittings with other fuel hose. Compatibility

issues may cause fuel leaks. Fuel Inlet

Fittings and Cross-Over Line: LS engines

require a cross-over fuel line to route the

fuel from one bank to the other. This is

typically done at the front of the engine.

Due to the variety of intake manifolds

and accessories a cross-over line must

be made for each application.

The supplied MSD Push-Lock AN

fittings are designed only for use with

the supplied fuel hose (Aeroquip AQP

FC598). We do not recommend mixing

Push-Lock style fittings and hoses from

different manufacturers. Doing so may

result in fuel leaks and expose other

dangerous incompatibilities.

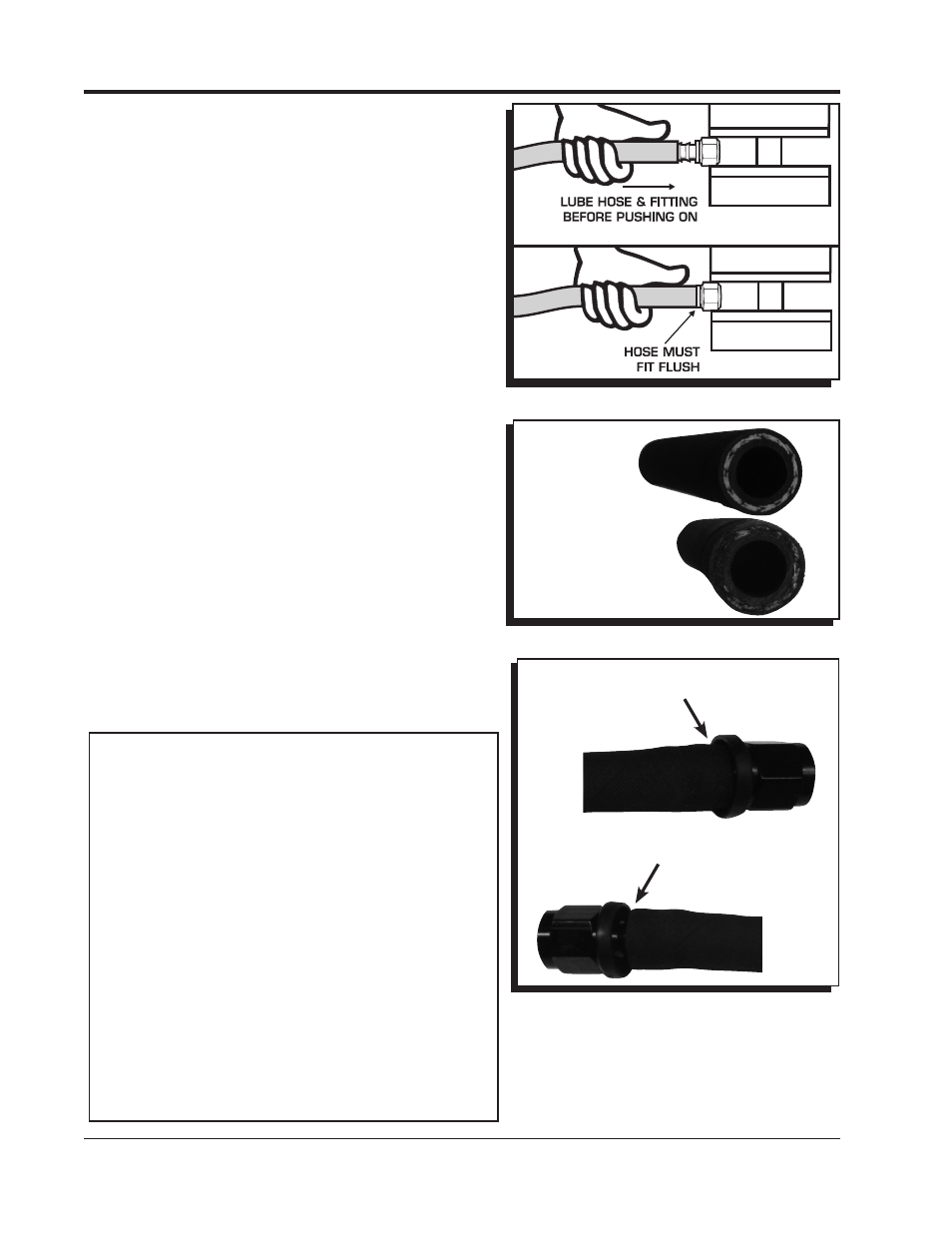

Figure 24 Installing Fuel Hose to the Push-Lock Fittings.

Figure 25 Severing the Hose Properly.

CORRECT CLEAN,

SQUARE CUT

Figure 26 Installed Push-Lock Fitting.

END OF HOSE IS FLUSH

WITH THE THIN EDGE

OF THE BEAUTY RING.

Properly Installed Push-Lock Fitting

INCORRECT

JAGGED, ROUGH

CUT RESULTS IN

A COMPROMISED

CONNECTION

E X C E S S I V E G A P T O

BEAUTY RING RESULTS

IN A COMPROMISED

CONNECTION.

Improperly Installed Push-Lock Fitting

MSD supplies a length of fuel hose and two 90° -6AN

fittings to prepare a fuel crossover line. The fittings utilize

Push-Lock technology and are designed exclusively for

use with the supplied hose. These fittings do not use

clamps, however it is imperative to follow the installation

instructions.

Proper installation begins with a clean, square cut of

the hose. A hose cutting tool or new razor blade are

recommended. When installing the hose it is important

that the hose is pushed on all the way to the thin beauty

ring (Figure 24). This means the hose should fully overlap

the inboard barb. Too little of engagement, as well as over-

engagement, will result in a compromised connection

that is prone to failure.

1. Determine the length of hose needed. Mark the hose

and cut it using a hose cutter or new razor blade.

There should be minimal disturbance of the outer

jacket, braids and inner liner. The cut plane should

be perpendicular to the hose axis. (Figure 25).

2. Before installing the hose to the fitting, it is important

to anchor the fitting. Proper installation cannot be

achieved by holding the hose and fitting in your hands.

For best results, the hose should be installed with

minimal twisting or pausing.

3. Apply a light coat of oil to the barbs on the fitting and

inside the hose. Use care not to get oil on the outside

of the hose as it will be impossible to get a firm grip

on the hose.

4. With the fitting anchored securely, push the hose over

the barbs. The hose is properly installed when it is flush

with the thin edge of the beauty ring (Figure 26). At

this point, the hose end should have rolled over the

inboard barb.