2 typical field wiring diagram, 8 side and bottom supply air blower, Performance – York D2EB030 User Manual

Page 11: 9 additional static resistance, Table 9: additional static resistance, Control wiring power wiring

360101-XTG-B-0508

Johnson Controls Unitary Products

11

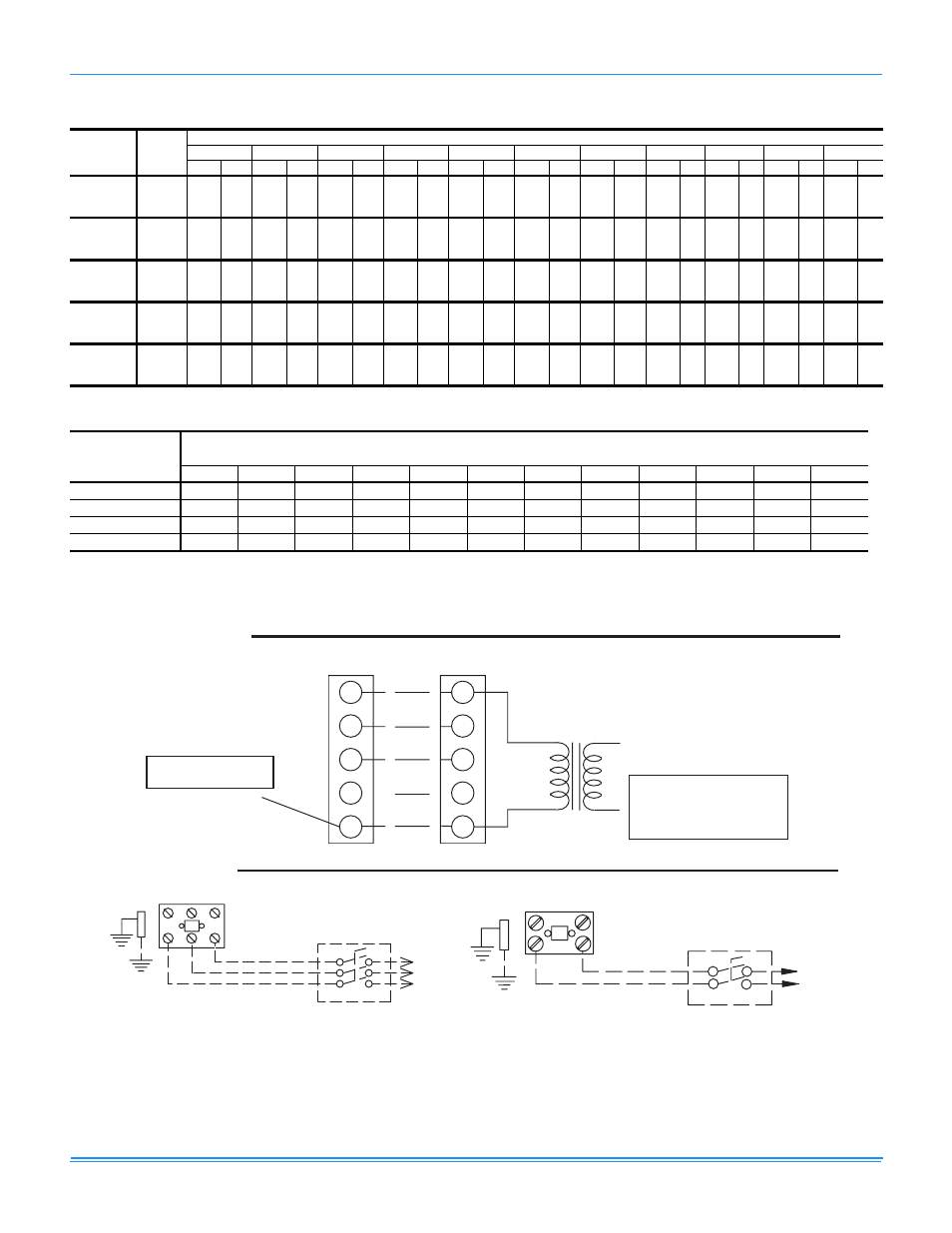

Note: 1. Deduct these resistance values from the available external static pressure shown in the respective Blower Performance Table.

2. The pressure thru the economizer is greater for 100% outdoor air then for 100% return air. If the resistance of the return air duct

system is less then 0.25 IWG, the unit will deliver less CFM during full economizer operation.

FIGURE 2 - TYPICAL FIELD WIRING DIAGRAM

TABLE 8: SIDE AND BOTTOM SUPPLY AIR BLOWER PERFORMANCE

Model No.

DEB

Blower

Speed

Setting

External Static Pressure (Inches Water Gauge)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

CFM

W

CFM

W

CFM

W

CFM

W

CFM

W

CFM

W

CFM

W

CFM W CFM W CFM W CFM W

030

(2.5)

High

-

-

-

-

-

-

-

-

1171

504

1080

486

990

468

888

456

786

444

-

-

-

-

Medium

1080

351

1021

341

961

331

902

321

841

305

781

290

-

-

-

-

-

-

-

-

-

-

Low

810

261

765

240

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

036

(3.0)

High

-

-

-

-

1440

605

1361

581

1273

555

1185

530

1097

504

1004 480

912

456

-

-

-

-

Medium

1465

531

1395

512

1325

492

1255

473

1167

446

1079

419

992

392

-

-

-

-

-

-

-

-

Low

1316

473

1260

455

1204

438

1148

420

1069

396

990

372

911

348

-

-

-

-

-

-

-

-

042

(3.5)

High

-

-

-

-

1728

725

1633

697

1527

666

1422

635

1317

605

1205 576 1094 547

-

-

-

-

Medium

-

-

1674

614

1590

590

1506

567

1400

535

1295

502

1190

470

1063 428

-

-

-

-

-

-

Low

1579

567

1512

546

1444

525

1377

504

1282

476

1188

447

1093

418

-

-

-

-

-

-

-

-

048

(4.0)

High

-

-

1985

870

1939

850

1897

830

1813

800

1728

770

1644

740

1559 707 1474 673 1389 640

-

-

Medium

1694

690

1662

673

1629

657

1597

640

1542

623

1486

607

1431

590

1336 563 1240 537

-

-

-

-

Low

1385

520

1349

510

1312

500

1276

490

1235

480

-

-

-

-

-

-

-

-

-

-

-

-

060

(5.0)

High

-

-

-

-

2450 1213 2366 1165 2282 1117 2198 1068 2114 1020 1989 993 1864 967 1739 940

-

-

Medium

2339 1170 2275 1118 2211 1067 2147 1015 2083

963

2019

912

1955

860

1854 824 1753 788 1652 752

-

-

Low

1929

940

1877

903

1824

867

1772

830

1720

793

1667

757

1615

720

1586 706 1557 691 1528 677

-

-

TABLE 9: ADDITIONAL STATIC RESISTANCE

Description

Resistance, IWG

CFM

500

600

700

800

900

1,000

1,100

1,200

1,300

1,400

1,500

1,600

Wet Evaporator Coil

.01

.01

.01

.02

.03

.04

.05

.06

.07

.08

.09

.09

Economizer

.00

.00

.00

.01

.01

.01

.01

.02

.03

.04

.05

.06

Filter/Frame Kit

.01

.02

.02

.02

.02

.02

.03

.03

.03

.03

.04

.05

Electric Heat

.02

.03

.03

.03

.04

.04

.05

.06

.07

.08

.09

.10

R

G

W

R

G

C

Y

Y

W

C

THERMOSTAT

PROGRAMMABLE

THERMOSTAT ONLY

UNIT TERMINAL STRIP

24 VOLT

TRANSFORMER

NOTE:

HEAT ANTICIPATOR

SHOULD BE SET AT 0.25

AMPS FOR ALL MODELS

Minimum wire size of 18 AWG

wire should be used for all field

installed 24 volt wire.

** =

Only required on units with

supplemental electric heat.

* =

**

*

CAUTION: Label all wires prior to disconnection

when servicing controls. Wiring errors

can cause improper and dangerous

operation. Verify proper operation

after servicing.

CONTROL WIRING

POWER WIRING

CONTACTOR

FIELD SUPPLIED

DISCONNECT

THREE

PHASE

POWER

SUPPLY

GROUND

LUG

CONTACTOR

FIELD SUPPLIED

DISCONNECT

SINGLE

PHASE

POWER

SUPPLY

GROUND

LUG

REFER TO ELECTRICAL DATA

TABLES TO SIZE THE DISCON-

NECT SWITCH, WIRING AND

OVERCURRENT PROTECTION.

REFER TO ELECTRICAL DATA

TABLES TO SIZE THE DISCON-

NECT SWITCH, WIRING AND

OVERCURRENT PROTECTION.