Theory of operation, Control board – Lincoln Electric V155-S User Manual

Page 29

THEORY OF OPERATION

E-5

E-5

INVERTEC® V155-S

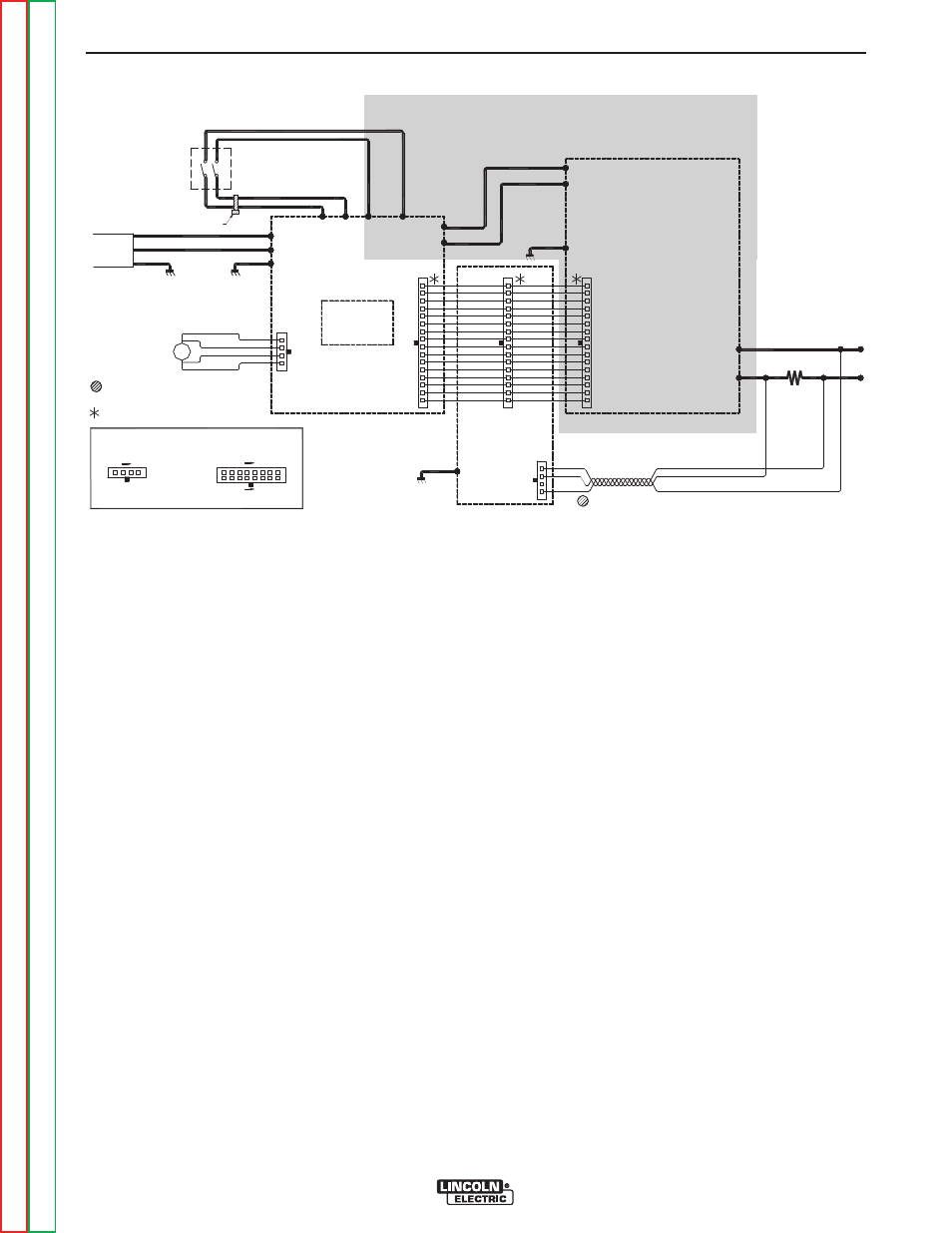

CONTROL BOARD

The Control Board receives status and analogue sig-

nals from the inverter board, input board and various

sensors and feeds this information to the Weld

Controller.

The Weld Controller is a micro-processor that uses

these signals along with input from the Mode Switch

and the Control Potentiometer to make decisions and

change the machine mode and output to satisfy the

requirements as decided by the operator. these

changes are relayed to the PWM circuit on the Inverter

Board to regulate the gate signals to the IGBT”s

FIGURE E.5 — CONTROL BOARD

The Weld Controler also responds to thermal and input

errors to shut down the machine output. The error

information is then displayed by the three LEDʼs on the

front panel.

The Mode Switch , the Control Potentiometer and the

three LEDʼs are all mounted on the Control Board.

CONTROL BOARD

W05X0708-1

(SCHEMATIC: X0708)

JP1

INPUT BOARD

W05X0701

(SCHEMATIC: X0701)

115/230Vac

50/60 Hz

ON/OFF SWITCH

5

2

N

L

G

WIRE TIE

4

1

BLUE

WHITE

WHITE

BLUE

WHITE

BLACK

AC2

AC1

PE

PWR2

PWR1

PWR4 PWR3

DC+

RED

DC-

BLACK

PCB CONNECTOR CAVITY NUMBERING SEQUENCE

(VIEWED FROM COMPONENT SIDE OF P.C. BOARD)

RIBBON CABLE

TWISTED CABLE

1

FAN

WHITE

RED

4

2

4 PINS

1

PE

RECONNECT

BOARD

W05X0408

(SCHEMATIC: X0408)

BLACK

JP4

BLUE

16

16 PINS

15

JP1

JP1

DC+

RED

DC-

BLACK

Y/G PE

INVERTER BOARD

W05X0519

(SCHEMATIC: X0519)

BLACK

RED

JP2

WHITE

W

HIT

E

P1

N1

BL

AC

K

RE

D

SHUNT

-

+