Installation, Warning – Lincoln Electric V155-S User Manual

Page 13

INSTALLATION

A-5

A-5

INVERTEC® V155-S

TIG WELDING

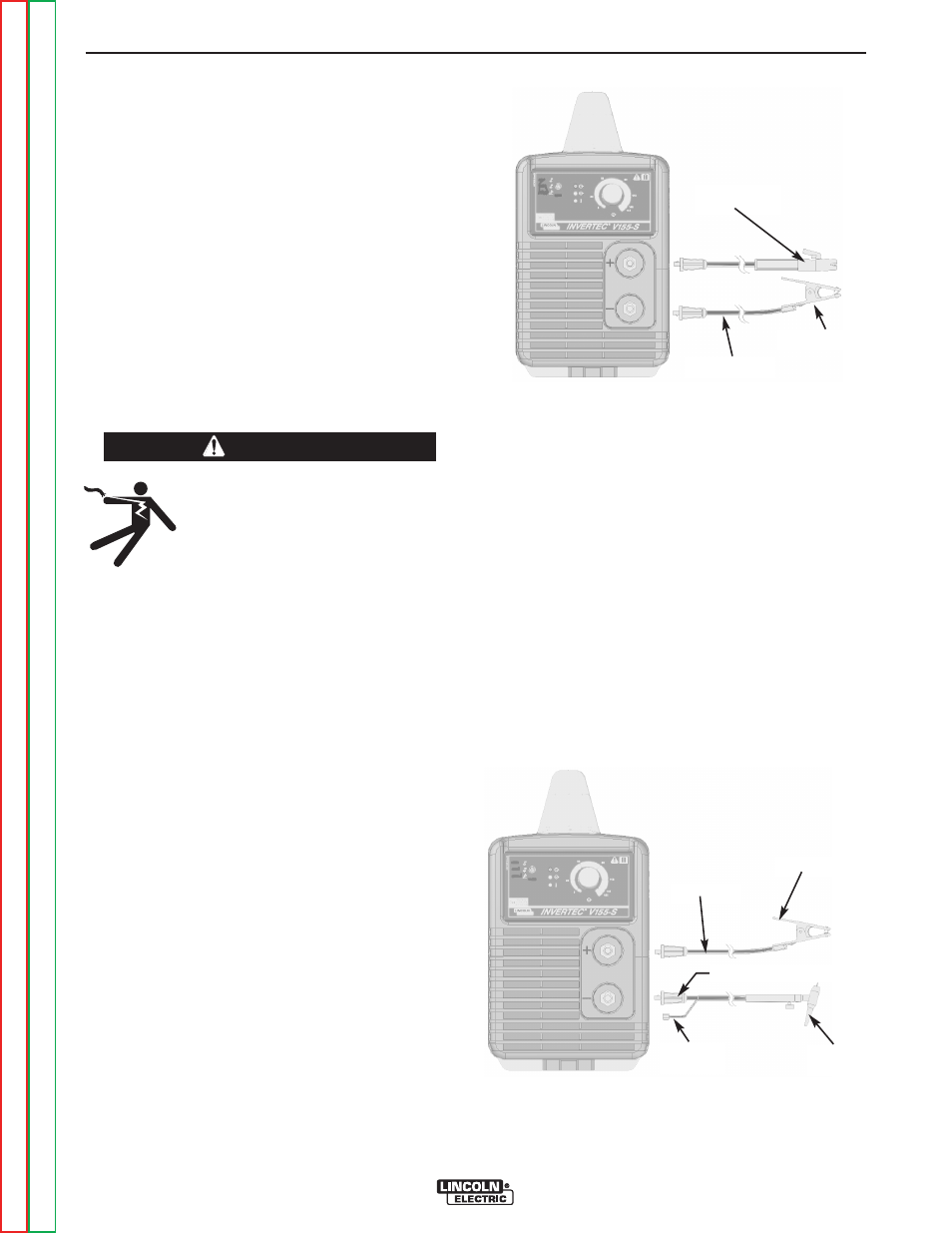

This machine does not have a built in Gas Solenoid so

a one piece gas valve TIG Torch is required. A K960-2

Twist-Mate™ TIG Torch adapter is also required. Refer

to the accessories section for more information about

TIG Torches and required Twist-Mate™ adapter. Most

TIG welding is done with DC(-) polarity shown here. If

DC(+) polarity is necessary switch the cable connec-

tions at the machine. (See Figure A.2)

Connect the torch cable to the (-) terminal of the

machine and the work clamp to the (+) terminal. Insert

the connector with the key lining up with the keyway

and rotate approximately 1/4 turn clockwise. Do not

over tighten. Finally, connect the Twist-Mate™ adapter

gas hose to the gas regulator on the cylinder of gas to

be used.

FIGURE A.2

Work Clamp

Twist-Mate™ Adapter K-960-2

Work Cable

Gas Valve

TIG Torch

Gas Hose

To Bottle

ARFU (Auto-Restore Fuse)

The dual input voltage machine is provided with the

ARFU device. It operates only when the input is con-

nected to the 120Vac mains and protects from input

overcurrent. When active, the "Thermal LED" lights

(see "Controls and Operational Features" in the

Operation Section).

Note: The ARFU device operates independently from

the machine's duty-cycle.

OUTPUT CONNECTIONS

A quick disconnect system using Twist-Mate™ cable

plugs is used for the welding cable connections. Refer

to the following sections for more information on con-

necting the machine for operation of stick welding

(SMAW) or TIG welding.

ELECTRIC SHOCK can kill.

• Keep the electrode holder and

cable insulation in good condition.

• Do not touch electrically live parts

or electrode with skin or wet cloth-

ing.

• Insulate yourself from work and ground.

• Turn the input line Switch on the INVERTEC®

V155-S “off” before connecting or disconnecting

output cables or other equipment.

-----------------------------------------------------------

STICK WELDING (SMAW)

First determine the proper electrode polarity for the elec-

trode to be used. Consult the electrode data for this infor-

mation. Then connect the output cables to the output ter-

minals of the machine for the selected polarity. Shown

here is the connection method for DC(+) welding. (See

Figure A.1)

Connect the electrode cable to the (+) terminal and the

work clamp to the (-) terminal. Insert the connector with

the key lining up with the keyway and rotate approximate-

ly 1/4 turn clockwise. Do not over tighten.

For DC(-) welding, switch the cable connections at the

machine so that the electrode cable is connected to (-)

and the work clamp is connected to (+).

Work Clamp

Work Cable

Electrode

Holder

FIGURE A.1

WARNING