Installation, Warning – Lincoln Electric V155-S User Manual

Page 12

INSTALLATION

A-4

A-4

INVERTEC® V155-S

INPUT POWER CONNECTION

Check the input voltage, phase, and frequency sup-

plied to this machine before turning it on.

The allowable input voltage is indicated in the techni-

cal specification section of this manual and on the rat-

ing plate of the machine. Be sure that the machine is

grounded.

Make sure the power available at the input connection

is adequate for normal operation of the machine. The

fuse rating and cable sizes are both indicated in the

technical specification section of this manual.

Fuse the input circuit with time delay fuses marked “D”

or delay type

1

circuit breakers. Using fuses or circuit

breakers smaller than recommended may result in

“nuisance” shut-offs from welder inrush currents even

if not welding at high currents.

1

Also called “inverse time” or “thermal/magnetic” circuit breakers.

These circuit breakers have a delay in tripping action that decreases

as the magnitude of the current increases.

The INVERTEC® V155-S is recommended for use on

an individual branch circuit.

120V INPUT

The rated output of the INVERTEC® V155-S is avail-

able when connected to a 30A branch circuit. When

connected to a branch circuit with lower ampacity,

lower welding current and duty cycle must be used. An

output guide is provided below. The values are approx-

imate and must be adjusted downward if the fuse or

circuit breaker trips off. Other loads on the circuit and

fuse/circuit breaker characteristics will affect the avail-

able output. Do not exceed these welding conditions:

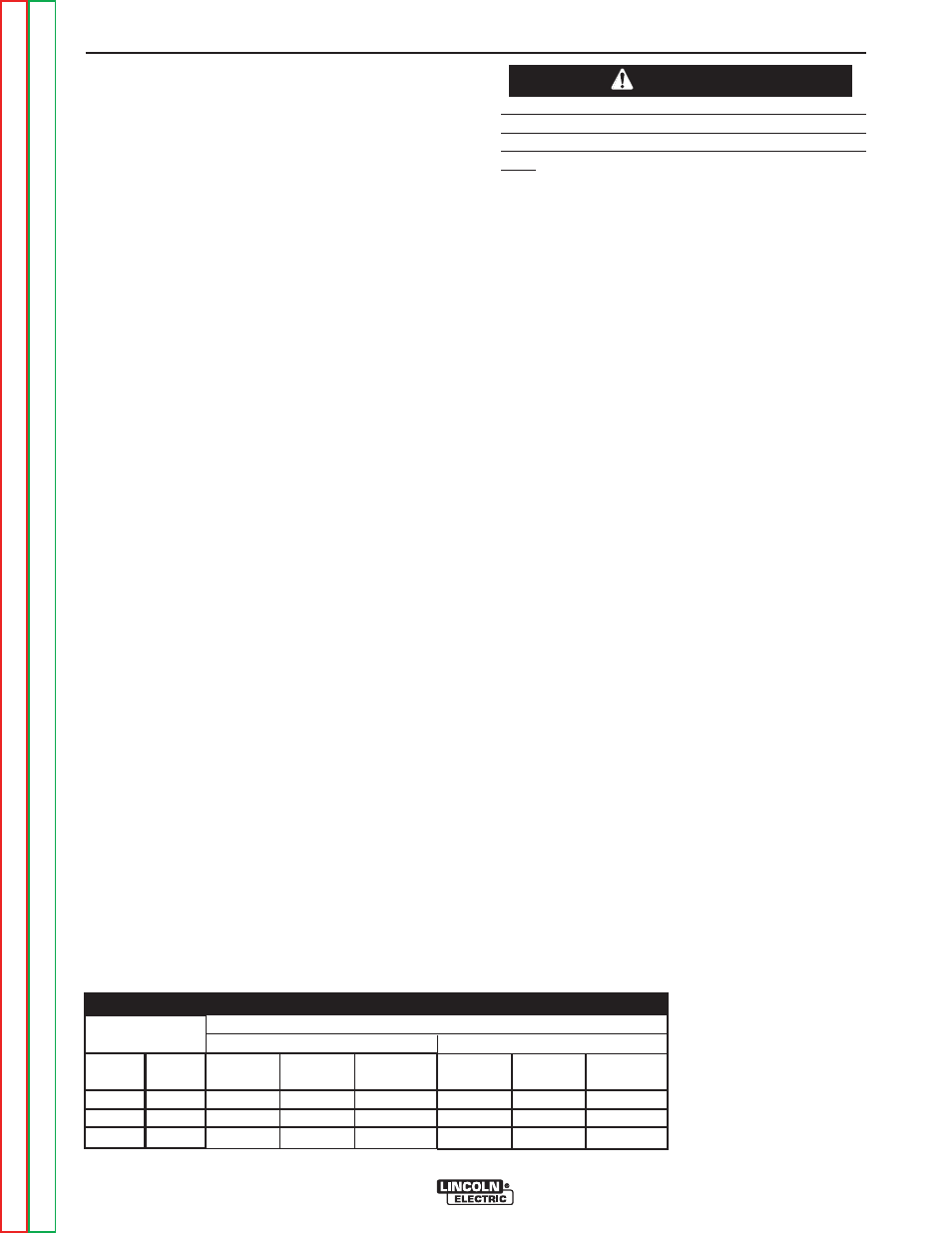

(See Table A.1)

The INVERTEC® V155-S is provided with a 120/230V

cable, 6.6ft.(2m) in length, with a 15Amp 5-15P plug

molded onto the cord.

The INVERTEC® V155-S is supplied with an addition-

al 20A plug that can replace the 15A plug to achieve

higher output. To install the supplied 20A plug:

Connect the white (neutral) wire under terminal clamp

with silver screw, and black (hot) wire under terminal

clamp with brass screw. Connect green wire under ter-

minal clamp with green screw.

• Failure to wire as instructed may cause personal

injury or damage to equipment. To be installed or

checked by an electrician or qualified person

only.

---------------------------------------------------------------------------

230V INPUT

To achieve the full output capacity of the INVERTEC®

V155-S, 230VAC inputs should be used. The change

over is accomplished by replacing the 120VAC plug

with a 30 Amp 230VAC plug (NEMA 6-30P).

ATTACHMENT PLUG

In all cases, the green or green/yellow grounding wire

must be connected to the grounding pin of the plug, usu-

ally identified by a green screw.

All attachment plugs must comply with the Standard for

Attachment Plugs and Receptacles, UL498.

The product is considered acceptable for use only when

an attachment plug as specified is properly attached to

the supply cord.

The INVERTEC® V155-S will auto reconnect to either

120V or 230V supplies.

ENGINE DRIVEN GENERATOR

The machine is designed to operate on engine driven

generators as long as the auxiliary can supply ade-

quate voltage, frequency and power as indicated in the

"Technical Specification" Installation Section of this

manual. The auxiliary supply of the generator must

also meet the following conditions:

• Vac peak voltage: below 205V (for 115Vac input) or

410V (for 230Vac input).

• Vac frequency: in the range of 50 or 60 Hertz.

• RMS voltage of the AC waveform: 115Vac or

230Vac ± 10%

It is important to check these conditions because many

engine driven generators produce high voltage spikes.

Operation of this machine with engine driven genera-

tors not conforming to these conditions is not recom-

mended and may damage the machine.

WARNING

BRANCH

Plug

Rating

15 Amp

15 Amp

20 Amp

Branch

Rating

15 Amp

20 Amp

20 Amp

10% Duty

Cycle

65A

75A

85A

30% Duty

Cycle

55A

70A

75A

100% Duty

Cycle

45A

60A

60A

10% Duty

Cycle

100A

110A

130A

30% Duty

Cycle

85A

100A

130A

100% Duty

Cycle

75A

95A

95A

120V Input

Stick

TIG

Output Current

TABLE A.1