Theory of operation, Rotor field feedback and auxiliary power – Lincoln Electric EAGLE SVM192-A User Manual

Page 35

THEORY OF OPERATION

E-3

E-3

EAGLE™ 10,000

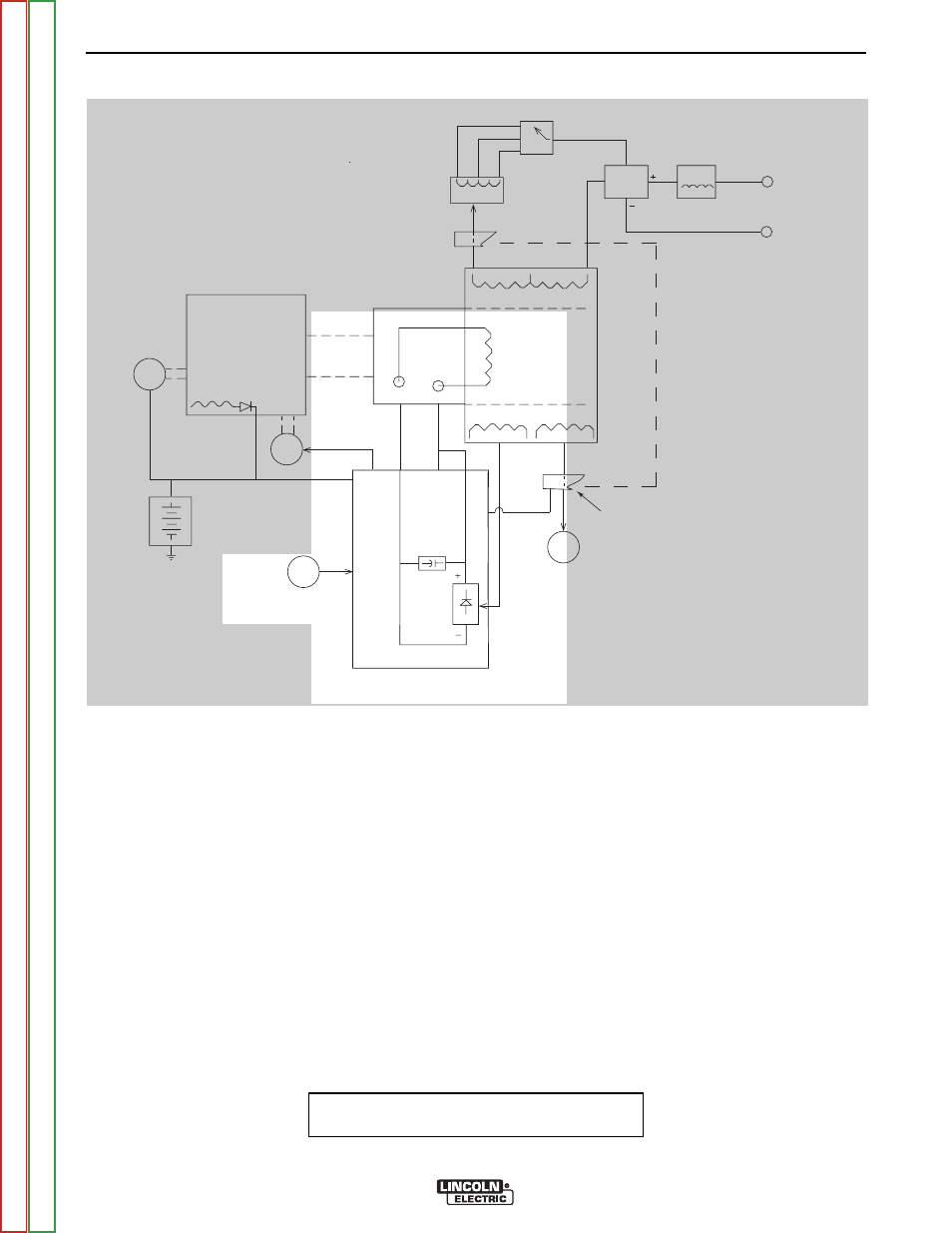

ROTOR FIELD FEEDBACK AND

AUXILIARY POWER

The AC voltage developed in the field winding is fed to

the full wave field bridge. The DC output of the bridge

is filtered by the field capacitor and controlled by the

printed circuit board according to the output control set-

ting.

This filtered and controlled voltage is fed to the

rotor winding via the brush and slip ring configuration.

As the feedback voltage is increased or decreased, the

outputs

of

the

weld

and

auxiliary

windings

are

increased or decreased.

When full field voltage is applied to the rotor and the

engine is running at high speed (3700 RPM), a 230 AC

voltage is developed in the stator auxiliary winding.

This winding is tapped to provide 115 VAC. The two

voltages, (115 VAC and 230 VAC), are connected to

the appropriate receptacles and offer 9000 watts (total)

of AC power.

FIGURE E.3 – ROTOR FIELD FEEDBACK AND AUXILIARY POWER

STARTER

ENGINE

BATTERY

IDLER

SOLENOID

OUTPUT

CONTROL

MECHANICAL

ROTAT ION

FIELD

CAPACITOR

ROTOR

SLIP

RINGS

115 & 230VAC

RECEPTACLES

ROTOR

STAT OR

STAT OR

REACTOR

RANGE

SWITCH

OUTPUT

BRIDGE

CHOKE

AC

AC

TERMINAL

TERMINAL

FLYWHEEL

ALTERNATOR

PRINTED CIRCUIT

BOARD

TOROID

TOROID

POSITIVE

POSITIVE

NEGATIVE

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion