Kiflyc\j_ffk`e, Dfkfi Page 64

Page 64

-62-

N(/((('Jc`[`e^KXYc\JXn

J

M

@:<

KiflYc\j_ffk`e^

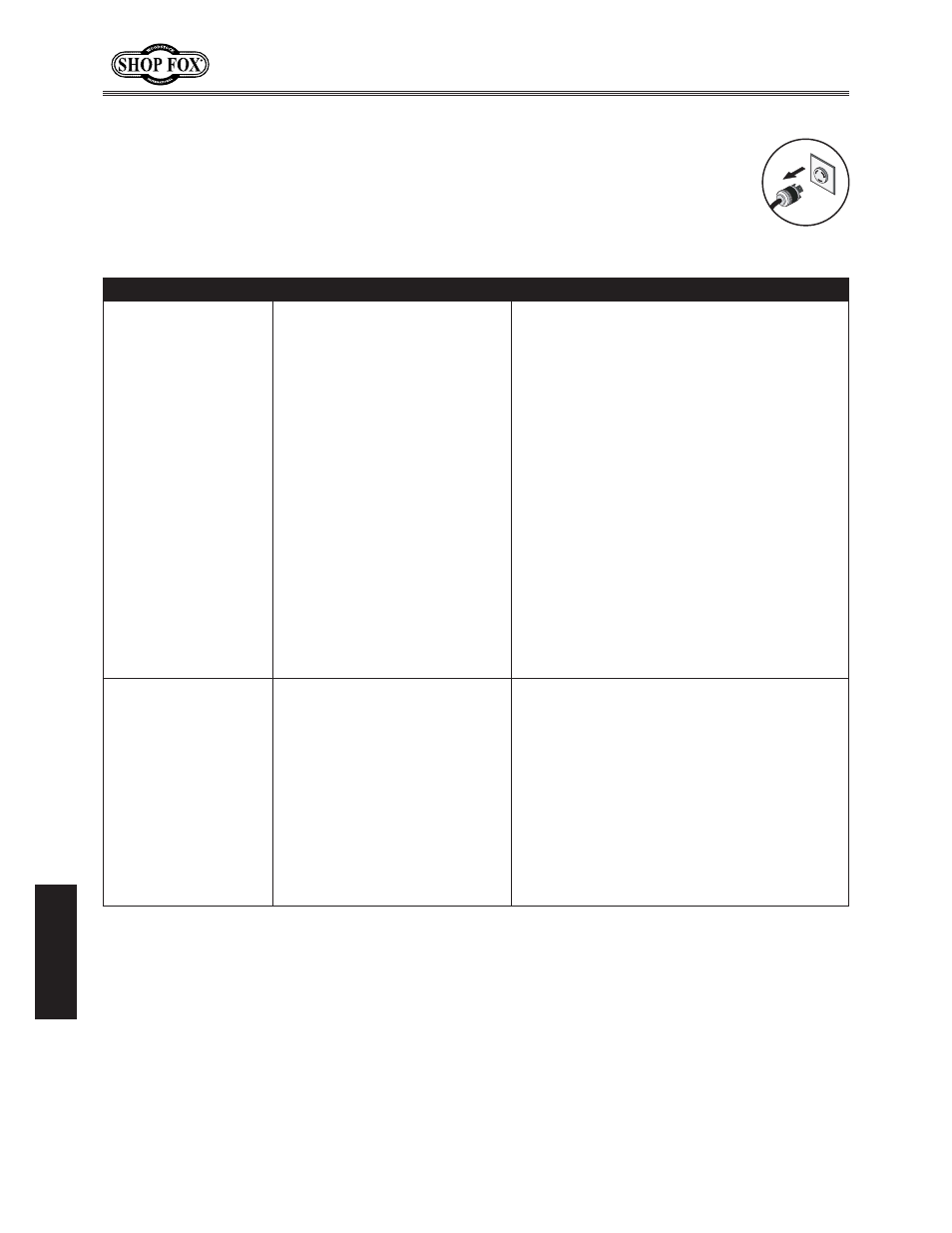

This section covers the most common problems and corrections with this type of

machine.

N8IE@E>;FEFKdXb\XepX[aljkd\ekjlek`cgfn\i`j[`jZfee\Zk\[Xe[

dfm`e^gXikj_Xm\Zfd\kfXZfdgc\k\jkfg

GIF9C

GFJJ@9C<:8LJ<

:FII<:K@M<8:K@FE

Machine does not start or a

breaker trips.

1. Emergency stop push-button is

engaged/faulty.

2. Power supply switched

OFF or is at

fault.

3. Blade guard limit switch engaged/

at fault.

4. Motor connection wired incorrect-

ly.

5.

Thermal overload relay has

tripped.

6. Wall fuse/circuit breaker is blown/

tripped.

7. Contactor not getting energized/

has burnt contacts.

8. Wiring is open/has high resistance.

9. Motor ON button or ON/OFF switch

is at fault.

10. Motor is at fault.

1. Rotate clockwise slightly until it pops out/replace

it.

2. Ensure power supply is switch on; ensure power sup-

ply has the correct voltage.

3. Move blade guard to the working position; replace

faulty limit switch.

4. Correct motor wiring connections.

5. Turn cut-out dial to increase working amps and push

the reset pin. Replace if tripped multiple times

(weak relay).

6. Ensure circuit size is suitable for this machine;

replace weak breaker.

7. Test for power on all legs and contactor operation.

Replace unit if faulty.

8. Check for broken wires or disconnected/corroded

connections, and repair/replace as necessary.

9. Replace faulty ON button or ON/OFF switch.

10. Test/repair/replace.

Machine stalls or is under-

powered.

1. Feed rate/cutting speed too fast

for task.

2. Workpiece material is not suitable

for this machine.

3. Belt(s) slipping.

4. Motor connection is wired incor-

rectly.

5. Motor bearings are at fault.

6. Start delay module is at fault.

7. Motor is at fault.

1. Decrease feed rate/cutting speed.

2. Only cut wood products; make sure moisture con-

tent is below 20% and there are no foreign materials

in the workpiece.

3. Replace bad belt(s), align pulleys, and re-tension.

4. Correct motor wiring connections.

5. Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.

6. Adjust to correct delay; replace module.

7. Test/repair/replace.

Dfkfi