9cx[\k`ck:xc`yixk`fe, Jzfi`e^9\cki\gcxz\d\ek, Jkfg – Woodstock W1811 User Manual

Page 57

-55-

N(/((('Jc`[`e^KXYc\JXn

J

M

@:<

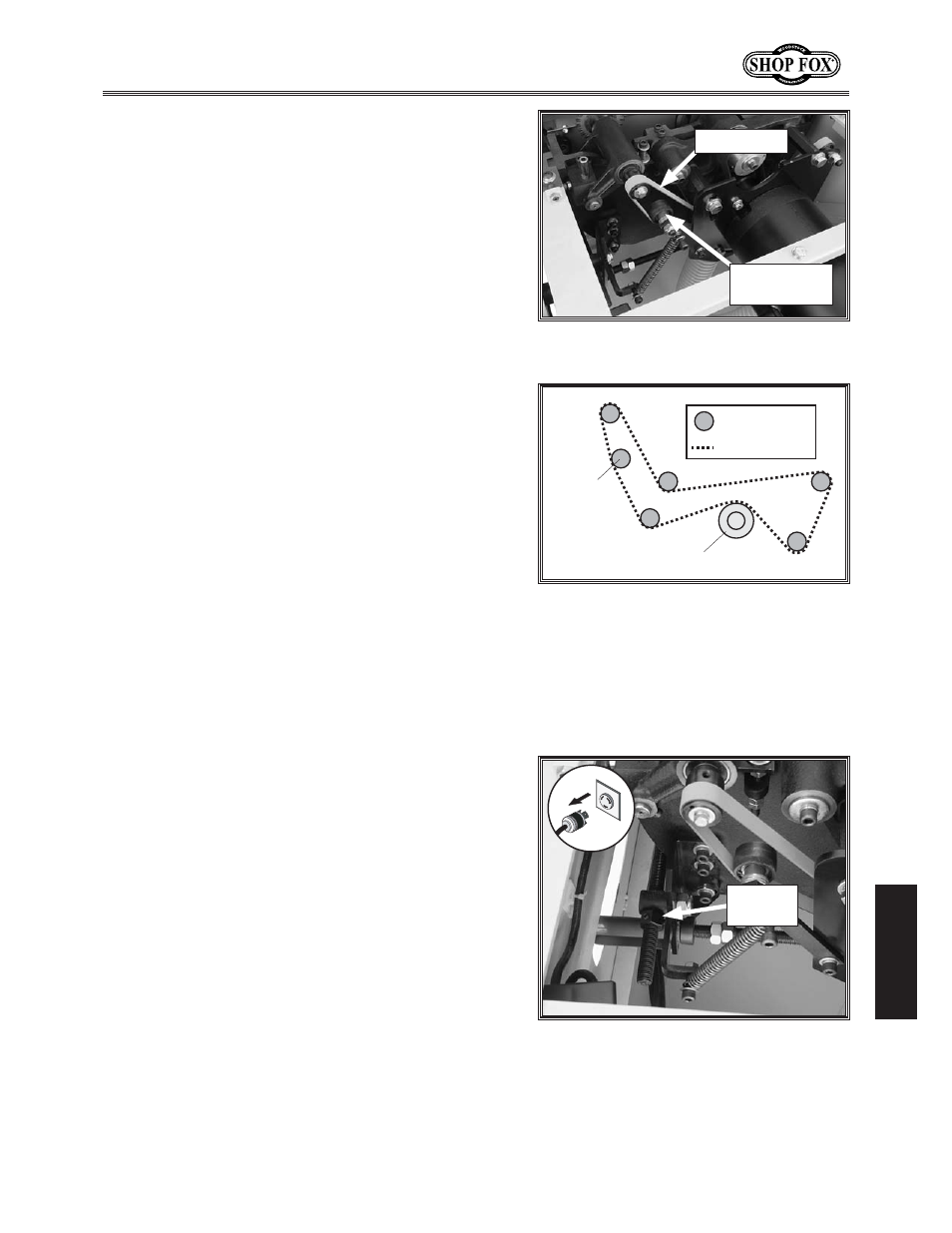

JZfi`e^9\ckI\gcXZ\d\ek

(% DISCONNECT SAW FROM POWER!

)% Tilt the blade to 45˚ and lower it as far as it will go.

*% Remove the motor cabinet door.

+% Pull the tensioner away from the scoring belt (=`^li\

0,) to relieve belt tension and remove the scoring

belt from the pulleys.

Efk\1Kliek_\Y\ckj`[\nXpjkfjhl\\q\k_\]cXk

gXikk_ifl^_k_\jdXcc^XgY\kn\\ek_\Yfkkfdglc$

c\pXe[k_\ZXjk`e^%

,% Put the new scoring belt on the pulleys as shown in

=`^li\0-, and push the tensioner against the scor-

ing belt to take up any slack.

-% Replace the motor cabinet door.

9cX[\K`ck:Xc`YiXk`fe

The blade tilt is calibrated at the factory, but can be

recalibrated if it changes during the life of the machine.

The 0° stop positions the blade square with the table.

'Jkfg

(% DISCONNECT SAW FROM POWER!

)% Move the blade tilt to 0° according to the gauge,

and raise the main blade as far as it will go.

*% Use a machinist's square to check if the blade is

square to the table.

— If the blade is not square to the table, loosen the

two set screws that secure the 0˚ tilt stop nut

shown in

=`^li\0.%

+% Adjust the stop nut and recheck the blade tilt as

many times as necessary until the blade is square to

the table.

,% Tighten the two set screws in the stop nut.

-% Check the blade tilt pointer mechanism to ensure

that it points to 0°.

— If the blade tilt pointer shows an incorrect tilt,

adjust it by loosening the cap screws, rotating the

pointer until it points to 0°, then tightening the

cap screws.

Scoring Belt

Tensionser

=`^li\0,% Replacing the scoring motor

belt (table removed for clarity).

Scoring Belt

IZch^dcZg

BdidgEjaaZn

2EjaaZn$GdaaZg

2HXdg^c\7Zai

=`^li\0-% Scoring belt installation

configuration.

=`^li\0.% Blade tilt stop nut (0°).

0° Tilt

Stop Nut