Lubrication, Maintenance – Woodstock SHOP FOX W1678 User Manual

Page 32

-30-

Lubrication

The four drum bearings in the bearing blocks

need to be lubricated every 20 hours of

operation. However, all other bearings used on

this machine are shielded and permanently

lubricated. Simply leave them alone until they

need to be replaced. DO NOT lubricate them, as

this will only attract dust and cause possible

premature bearing failure.

DO NOT apply grease on any exposed areas on

the sander like the feed conveyor chain,

sprockets, and the table lead screws. If you do,

sanding dust and abrasives will collect on these

parts and create a gummy mixture that can

hamper proper movement of components and

increase wear. Use a light machine oil and a dry

graphite lubricant.

To lubricate the sander, do these steps:

1. Unplug the double drum sander.

2. Clean the sander as outlined in General

Cleaning procedures on Page 34.

3. Open the dust hood to gain access to the four

drum-bearing-housing grease zerks. See

Figure 57.

4. Remove the grease zerk cap from the bearing

block housing, wipe all contamination off of

the zerk, and squirt two pumps of high-

quality lithium-base grease into the bearing.

DO NOT over-grease the bearing.

5. Coat the exposed areas of the table lead

screws with dry powdered graphite.

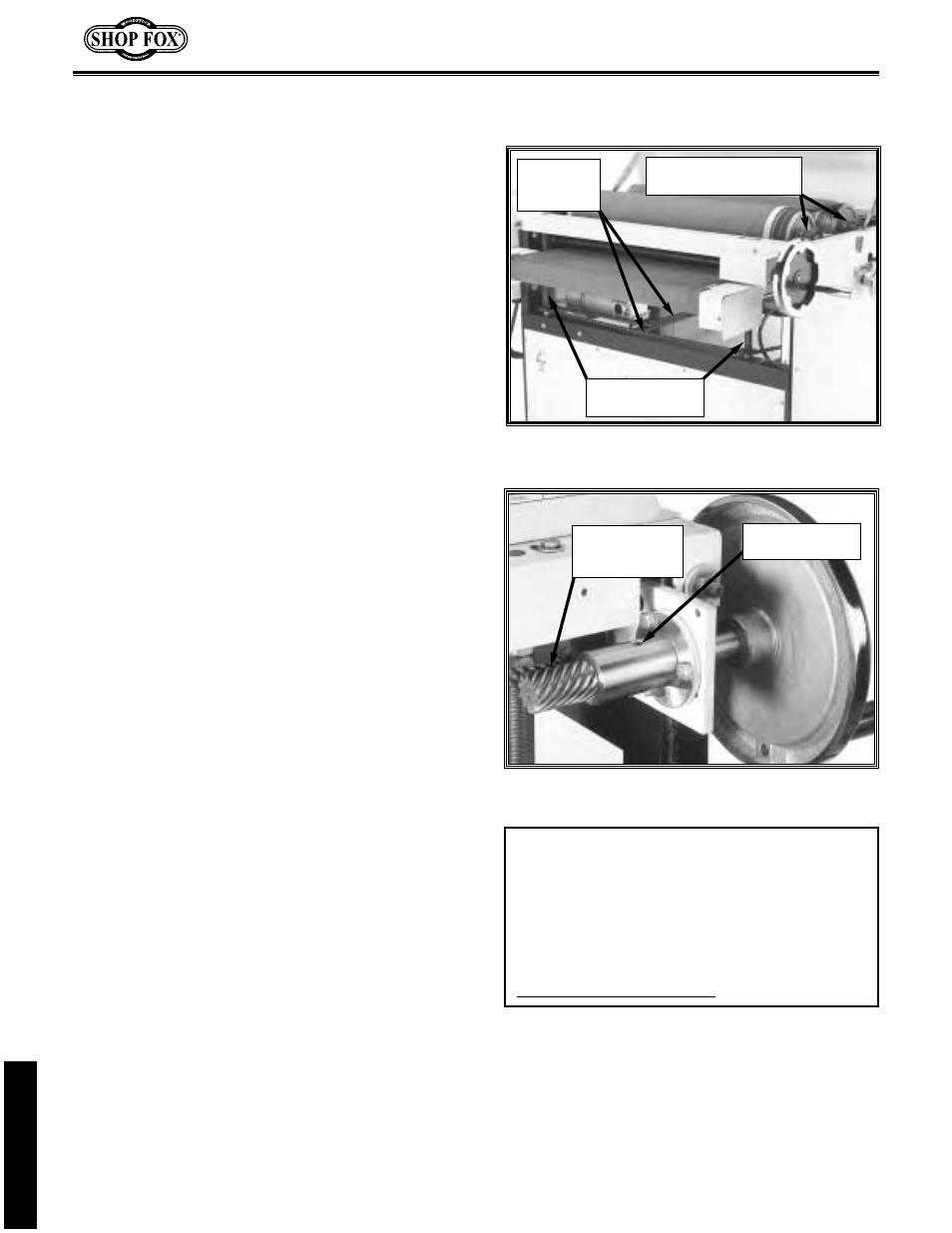

6. Coat the feed conveyor chain and sprockets

with a light machine oil, and use a rag to

wipe-off the residual oil. See Figure 52.

7. Put three drops of the machine oil in the

handwheel bushing oil port and a couple of

dabs of lithium-base grease on the

handwheel gears. See Figure 53.

8. Wipe off any loose grease and replace the

dust cap.

9. Repeat Steps 1 through 6 for the three

remaining drum bearings.

10.Close the dust hood and close the latches.

Figure 53. Handwheel bushing and gears.

Figure 52. Drum bearings, table head screws,

feed conveyor chain and sprockets.

Grease Drum Bearings

at Zerk Fittings

Light Oil on

Sprockets

and Chain

Dry Graphite

on Lead Screws

3 Drops of Light

Oil in Oil Port

White Lithium

Automotive

Grade Grease

MAINTENANCE

If any part of the sander becomes difficult to

operate, it is most likely caused by an

accumulation of sawdust. Immediately

troubleshoot the area and remove any

sawdust. Or contact

Woodstock

International, Inc.

Service and Support at 1-

360-734-3482 or send e-mail to: