Adjustments, Drums and pressure rollers – Woodstock SHOP FOX W1678 User Manual

Page 16

ADJUSTMENTS

-14-

Drums and Pressure

Rollers

To get the best sanding results and longest life

out of your sandpaper, both the front and rear

sanding drums must: (1) be square with the

conveyor table, (2) run parallel with each other

and parallel to the conveyor feed direction, and

(3) must be slightly staggered in height with one

another. Pressure-roller spring tension and height

must also be set correctly.

As you become more familiar with your sander

you can vary your sander settings to fine-tune

the machine for your ultimate sanding goals.

PART 1: Drum-to-Conveyor Squareness

For this adjustment, you will align the drums so the

drums are square with the feed conveyor belt

surface. See Figure 18.

To adjust the drum-to-conveyor squareness,

do these steps:

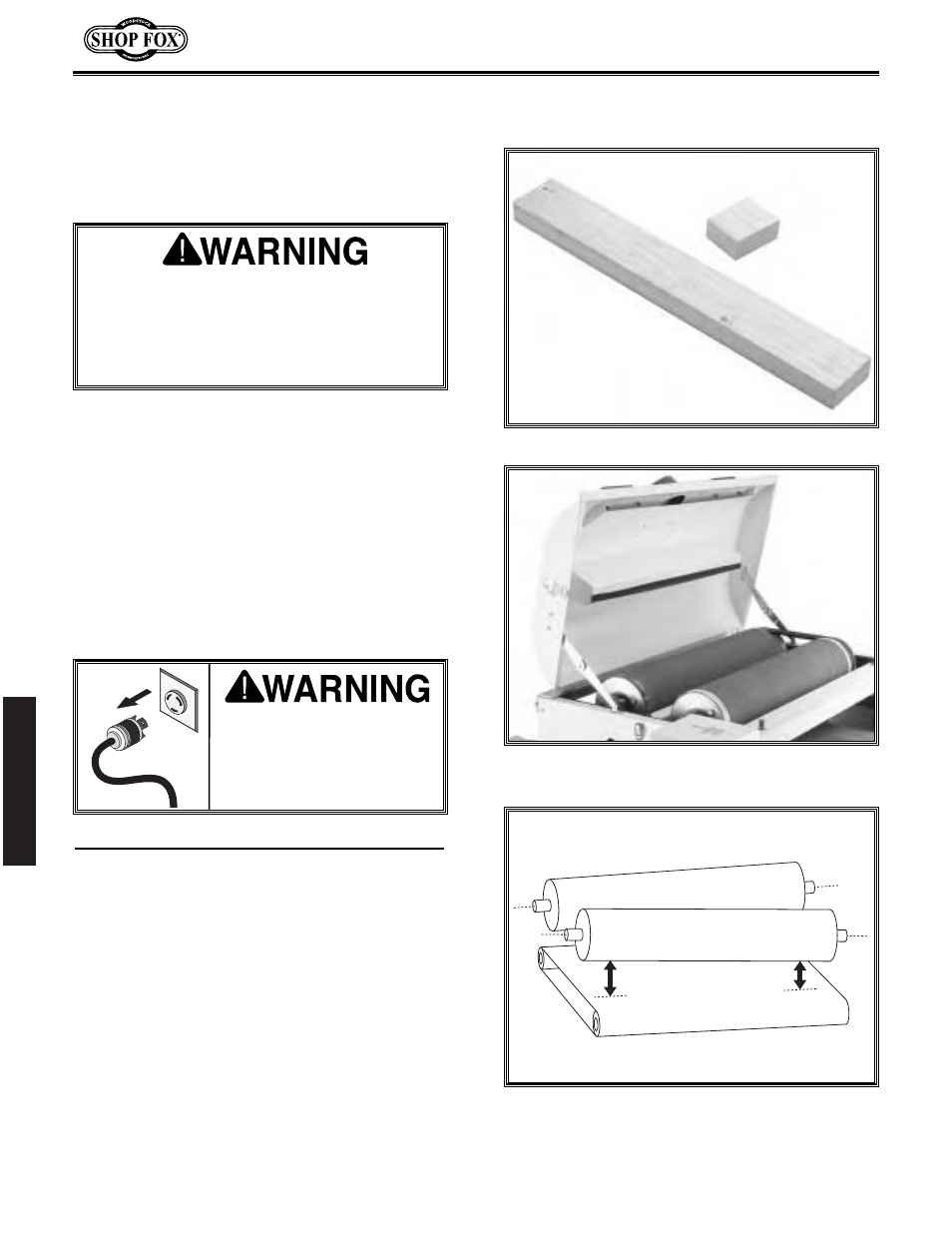

1. Make two gauge blocks from a quality piece

of straight two-by-four hardwood stud. One

block should be 30" long, and the other 2

5

⁄

8

"

long. See Figure 16.

2. Unplug the Double Drum Sander!

3. Unlatch and open the dust hood. See Figure 17.

Figure 17. W1678 dust hood open.

Figure 16. Gauge blocks for drum alignment.

ADJUSTMENTS

Figure 18. Drums to conveyor not square.

Adjust the sanding drums and pressure rollers

correctly. Complete PART 1, PART 2, PART 3,

and PART 4 of this section in sequence.

Otherwise, the sanding drums can grab and

project the workpiece damaging the sander,

and injuring you and bystanders!

Keep your drum sander

unplugged during these

adjustments. Otherwise,

serious personal injury

may occur!