Notice, Part 4: pressure roller adjustment, Adjustments – Woodstock SHOP FOX W1678 User Manual

Page 21

-19-

Figure 32. The 30" gauge block positioning.

Pressure

Roller

Height

Adjustment

Pressure

Roller

Spring Tension

Adjustment

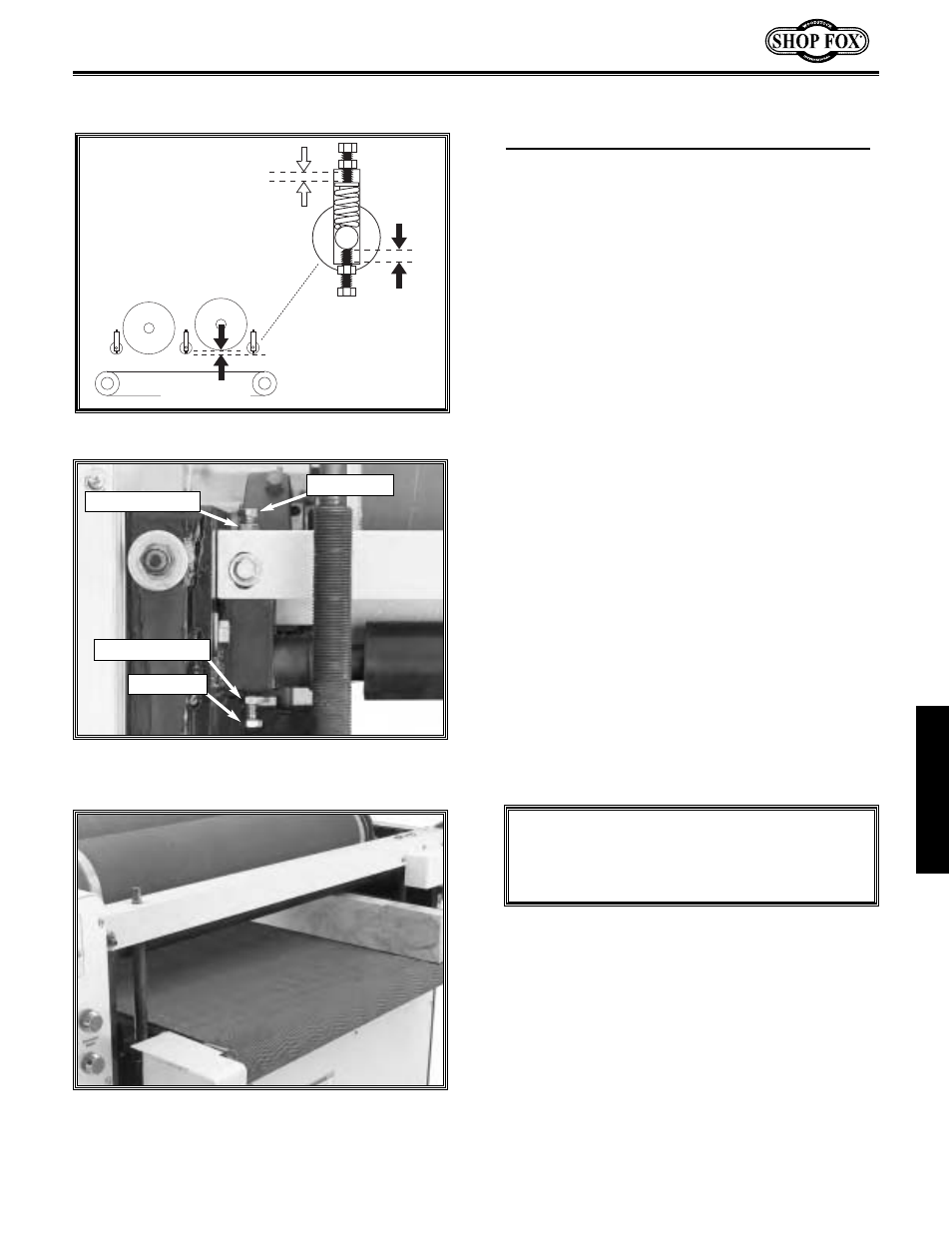

Figure 30. Pressure Roller Adjustment.

Figure 31. Pressure roller tension and height

bolts and jam nuts.

PART 4: Pressure Roller Adjustment

Depending on your sanding needs, adjust the

pressure roller height and spring tension. See

Figure 30.

To adjust pressure-roller height, do these steps:

1. Loosen all six height jam nuts. See Figure 31.

2. Position the 30" gauge block to one side of

the conveyor belt and under the three

pressure rollers. See Figure 32.

3. Turn the handwheel so the gauge block

barely touches the rear drum and the

handwheel tape is at the 12:00 position.

4. Now turn the handwheel counter-clockwise

exactly 2

1

⁄

2

turns.

5. Turn the pressure-roller height bolt until the

pressure roller just contacts the gauge block.

See Figure 31.

6. Hold the height bolt in position and tighten

the height jam nut.

7. Repeat Steps 1 through 6 at all rollers, and

remove the gauge block.

To adjust pressure-roller spring tension, do

these steps:

1. Loosen all six tension jam nuts, and back out

the tension bolt completely. See Figure 31.

2. Turn the tension bolt clockwise until it just

makes contact with the spring and has

resistance.

3. Turn the bolt one additional turn to adjust

the spring to a basic spring tension value.

4. Hold the tension bolt in position and tighten

the tension jam nut.

5. Repeat Steps 2 through 4 at all rollers.

6. Close and latch the dust hood, and check the

V-belt tension.

NOTICE

Too much pressure roller tension may cause the

workpiece to jam.

Tension Jam Nut

Tension Bolt

PRESSURE

ROLLER

Height Bolt

Height Jam Nut

ADJUSTMENTS

0.012" to 0.024"