Maintenance, Sanding belts, General – Woodstock SHOP FOX W1678 User Manual

Page 31

Sanding Belts

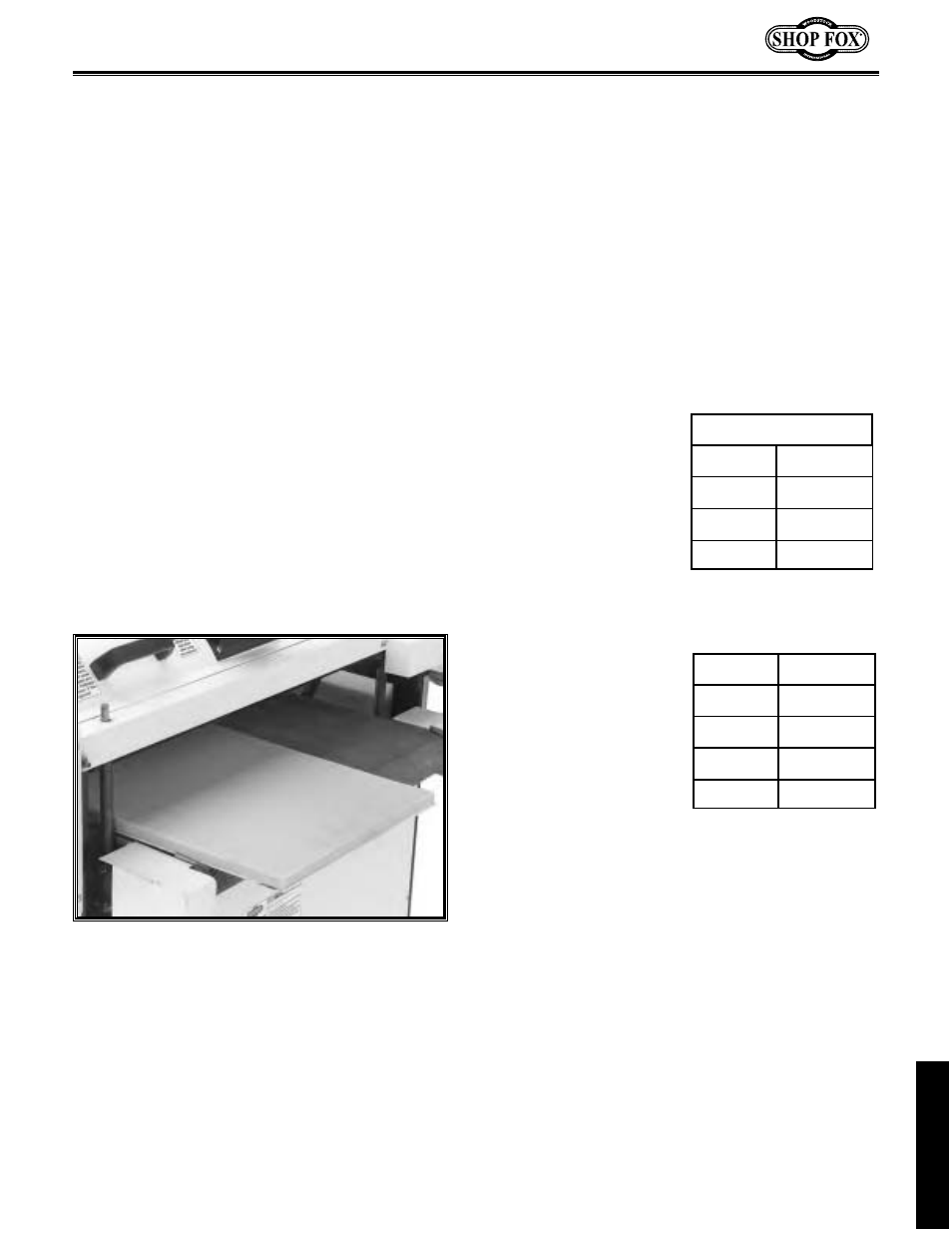

As sanding drums are used, the sandpaper can

quickly become "loaded" with sawdust. If not

removed, this sawdust may harden on the

abrasive surface and can glaze instead of sand

the wood, thus, rendering the sandpaper useless.

To avoid this condition, routinely clean the

sandpaper with a rubber gum abrasive cleaner

such as the D3003 PRO-STIK

®

15" x 20" cleaning

pad shown in Figure 51. to extend the life of

the sandpaper.

Discard all worn

sandpaper because

the grit will fall off

causing deep gouges

in the workpiece. Also

the glue used to hold

the grit to the paper

can rub off onto the

workpiece burning the

workpiece. Contrary to some beliefs, worn

abrasive belts are not the equivalent to the next

finer grit abrasive.

There are many types

of sandpaper you can

use. Aluminum Oxide

is excellent for

general wood shop

use. To the right is a

chart that groups

abrasives into

different classes, and

shows which grits fall into each class.

The Model W1678 allows you to use two

different grit sandpapers at once. The first

drum is fitted with a coarser grit than the

second. Usually this translates into

combinations of successive group types. A

common selection for a workpiece that is

planed before it is sanded, is the 100/150 grit

combination.

Overall, the general rule of thumb is to sand a

workpiece with sandpaper that uses

progressively higher grit numbers, with no one

grit increase of more than 50.

Ultimately, the type of wood you use and your

stage of finish will determine the best grit types

to install on your sander.

-29-

MAINTENANCE

General

Regular maintenance on your Model W1678 helps

ensure optimum performance. Inspect your

machine each time you use it for the following

conditions. Adjust, repair, or replace parts

when worn.

1. Inspect for loose bolts and panels.

2. Make sure the work area is clean, and remove

any tools or rags from the machine.

3. Replace worn electrical parts like the

emergency stop switch, ON and OFF push

buttons, and damaged cords and plugs.

4. Replace damaged sandpaper, motor V-belts,

or conveyor drive chains and sprockets.

5. Correct any other condition that could

hamper the safe operation of this machine.

6. Routinely clean the sandpaper with a PRO-STIK

®

15" x 20" cleaning pad shown in Figure 51.

GRIT RANGE

TYPE

60

80-100

120-180

220

Coarse

Medium

Fine

Very Fine

GRIT

PART #

REPLACEMENT SANDPAPER

60

100

150

D3162

D3163

D3164

Figure 51. PRO-STIK

®

15" x 20" cleaning pad.

MAINTENANCE