Troubleshooting, Operation – Woodstock SHOP FOX W1678 User Manual

Page 30

-28-

SSSSYYY

YM

M

M

MPPPPTTTTO

O

O

OM

M

M

M

PPPPO

O

O

OSSSSSSSSIIIIBBBBLLLLEEEE RRR

REEEEAAA

ASSSSO

O

O

ONN

N

N

H

H

H

HO

O

O

OW

W

W

W TTTTO

O

O

O RRR

REEEEM

M

M

MEEEEDD

D

DYYYY

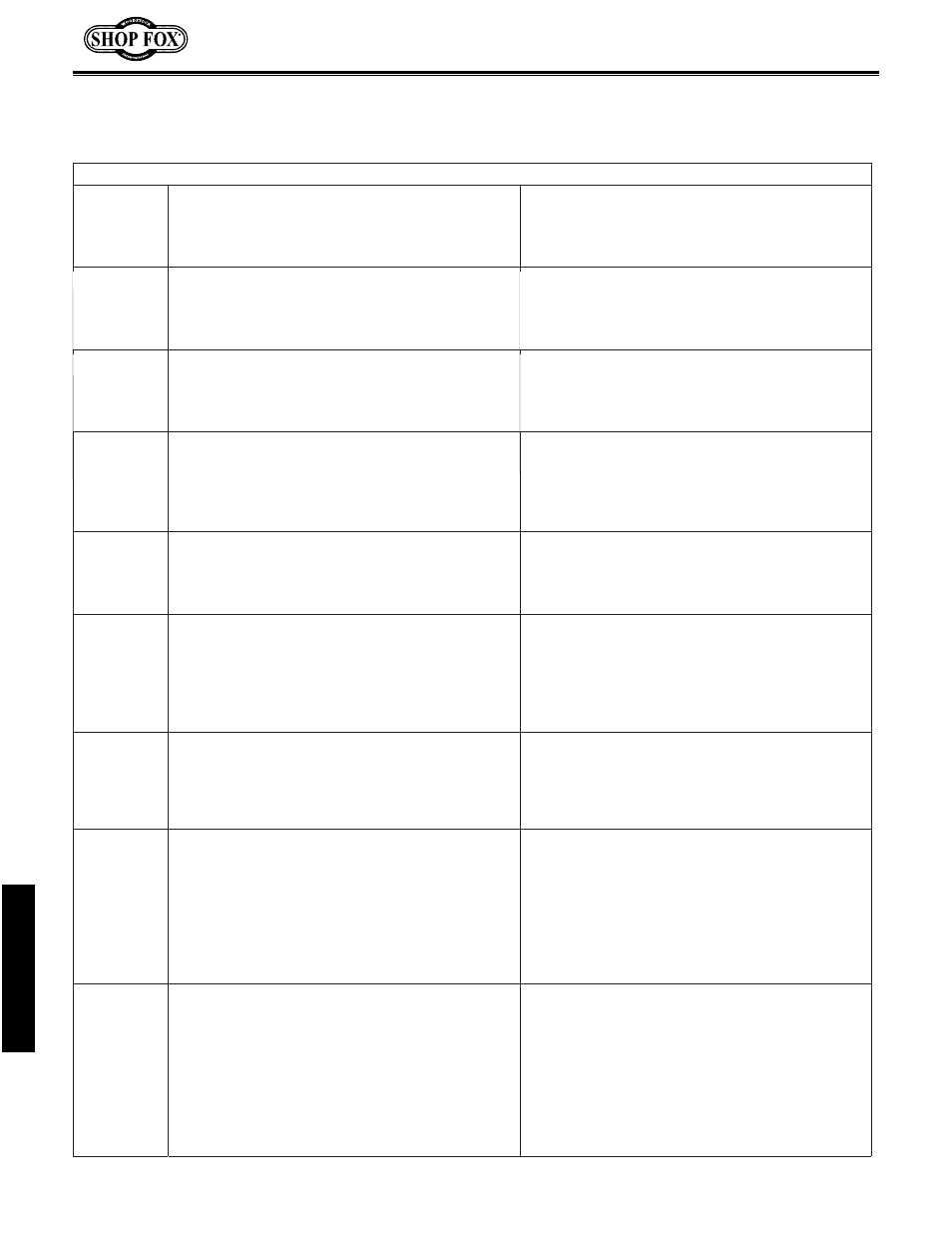

The feed

conveyor

belt stops

or chatters.

The conveyor belt tension is incorrect.

The conveyor belt tracking is incorrect.

Adjust the conveyor belt tension.

Adjust the conveyor belt tracking.

The sanded

surface is

glazed and

shiny.

The sandpaper is worn out.

The drums are only applying light pressure

against the sanded surface.

Replace the sandpaper.

Increase the sanding pressure on the workpiece

surface.

Long grooves

or high spots

on sanded

surface.

The sandpaper is damaged or uneven-bald wear

in certain areas.

Replace the sandpaper.

Remove and rewrap the sandpaper on the drums.

The wood

slips on the

feed

conveyor

belt.

The feed conveyor belt is slippery with sawdust

or the surface is worn.

Too much material is being removed in one

pass.

Clean or replace the feed conveyor belt.

Reduce the sanding load, and adjust the drums

and pressure rollers.

The left and

right edges

on wood are

rounded.

The drums are applying too much sanding force

on the workpiece and the free edges of the

sandpaper are rolling over the edges.

Reduce the force the drums are applying on

the workpiece surface.

The wood

thickness is

uneven

from

side-to-

side.

The drums are not square to the table.

The sandpaper is worn or clogged unevenly

from side-to-side.

Adjust the drums and pressure rollers.

Clean or replace the sandpaper.

Snipe is

evident on

the ends of

the wood.

Lack of outfeed or infeed support is causing the

snipe.

The drum height and the pressure roller

spring tension are incorrect.

Use roller tables and support the infeed and

outfeed of the workpiece.

Adjust the drums and pressure rollers.

The

sandpaper

clogs too

quickly.

The sandpaper grit is too fine or is worn out.

Too much wood is being removed at once.

The wood is wet, oily, or dirty.

The dust collection system is insufficient.

Replace the sandpaper.

Reduce the load on the sanding drums.

Sand only dry and clean wood.

Service the dust collection system or increase

the duct collector system efficiently.

The

sandpaper

tears.

The drums are not sanding parallel to direction

of conveyor belt feed.

Drums are not square with the table.

Sandpaper edges have overlapped or tape

has slipped.

Too much wood is being removed at once.

Adjust the drums and pressure rollers.

Adjust the drums and pressure rollers.

Wrap sandpaper on drums correctly and use a

heavy-duty tape.

Reduce the load on the sanding drums.

The sandpaper is unevenly crushed into the

hook-and-loop wrapping on the drums.

Troubleshooting

(Continued)

OPERATION