Faceplate turning, Notice – Grizzly G0694 User Manual

Page 32

-30-

Model G0694 (Mfg. Since 10/09)

Spindle Turning Safety Tips

•

When turning the lathe

ON, stand away from

the path of the spinning workpiece until the

lathe reaches full speed and you can verify

that the workpiece will not come loose.

•

Use the slowest speed when starting or stop-

ping the lathe.

•

select the right speed range and speed for

the size of the workpiece and the type of cut

(refer to

Adjusting Spindle Speed on Page

25 for detailed instructions and guidelines).

•

Learn the correct techniques for the tools you

use. if you are unsure about how to use the

lathe or any lathe tool, read books or maga-

zines about lathe techniques and seek train-

ing from experienced lathe users.

faceplate Turning

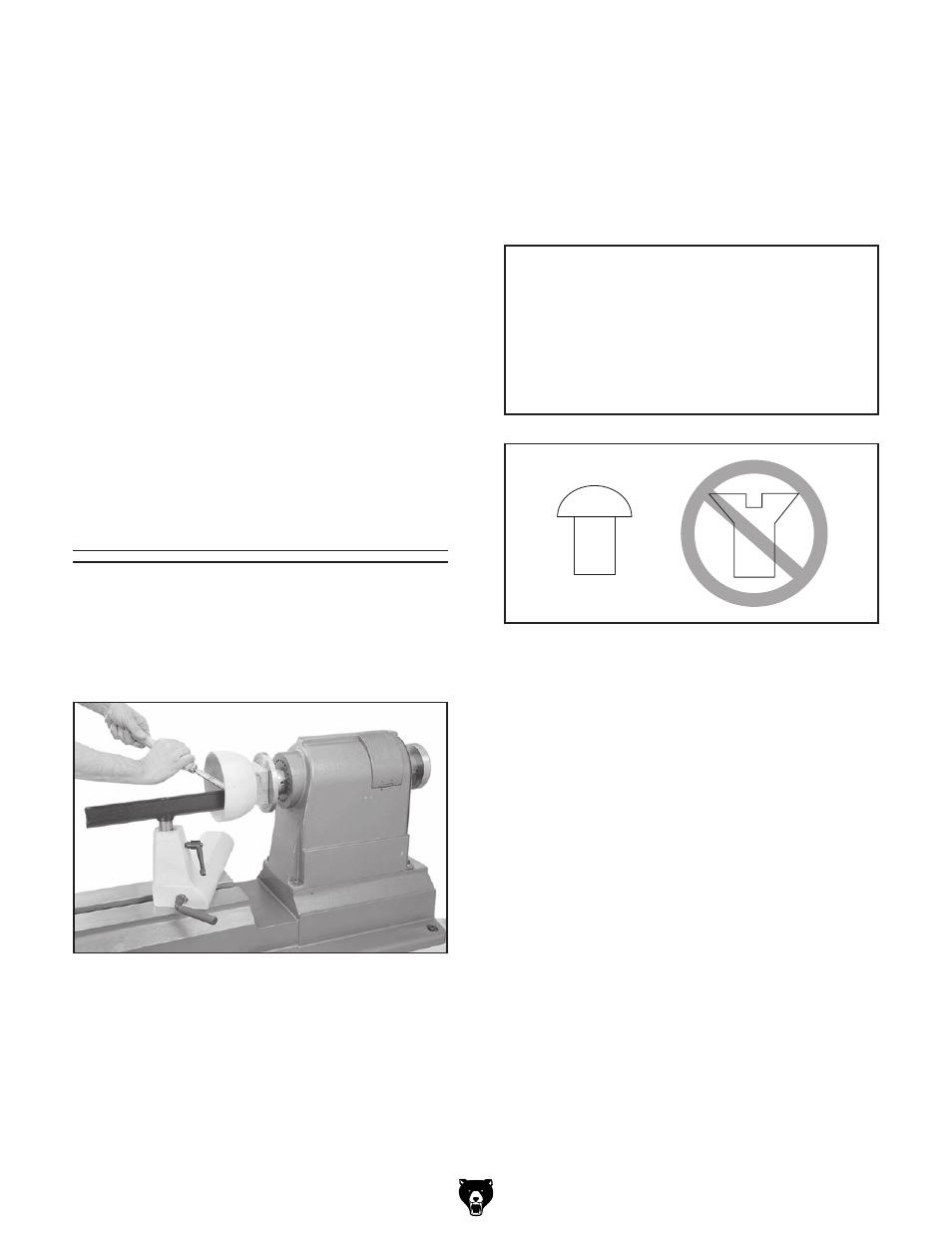

Faceplate turning is done when a workpiece is

mounted to the faceplate, which is then mounted

to the headstock spindle. this type of turning is

usually done with open-faced workpieces like

bowls or plates (see

figure 34 for an example).

figure 34. typical faceplate turning operation.

Mounting Workpiece on faceplate

1. Mark the workpiece center as in Spindle

Turning (see Page 28).

Note: Cut off corners of the workpiece to

make it as close to "round" as possible.

figure 35. Correct and incorrect screw types for

mounting faceplate to workpiece.

NOTICE

Only use tap screws or wood screws with

non-tapered heads (figure 35) to attach the

faceplate to the workpiece. Do NOT use dry-

wall screws or screws with tapered heads,

because they can split the faceplate or snap

off during operation.

2. Center the faceplate on the workpiece and

attach it with wood screws that do not have

tapered heads.

3. thread and secure the faceplate onto the

headstock spindle (refer to

Headstock/

faceplate on Page 24 for faceplate mount-

ing instructions).