Indexing, Notice – Grizzly G0694 User Manual

Page 28

-26-

Model G0694 (Mfg. Since 10/09)

4. position the belt on the motor and spindle

pulleys for the correct speed range.

5. Loosen the lock lever and allow the motor

weight to tension the belt. there should be

almost no belt looseness or belt deflection.

Note: If the motor does not hang freely

against the belt, you may have to manually

push the height lever to tension the belt.

6. tighten the lock lever.

7. Close the belt access panel and cabinet

door.

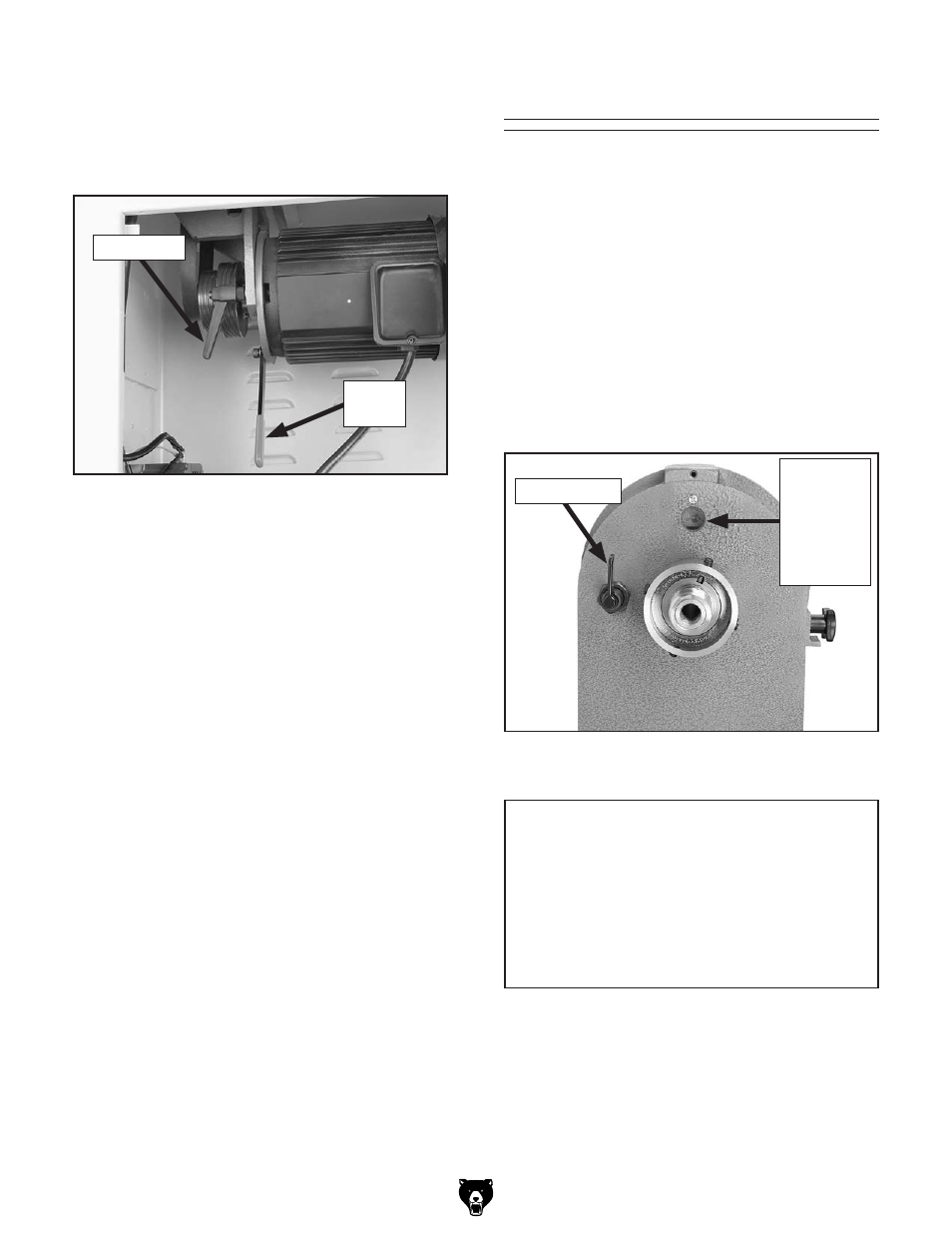

Indexing

indexing on a lathe is typically used for workpiece

layout and other auxiliary operations that require

equal distances around the workpiece circumfer-

ence, such as clock faces or inlays.

By applying the spindle lock into one of the 24

holes in the spindle, the workpiece can be posi-

tioned to one of 24 equal points that are 15°

degrees apart.

For special sequencing of positions, each spindle

position has its own number, which can be viewed

through the viewing window, as shown in

figure

25, on the outboard side of the headstock.

3. open the cabinet door, loosen the lock

lever, pull up on the height lever to raise the

motor to the highest position, then re-tighten

the lock lever to secure the motor in place

(

figure 24).

NOTICE

Always disconnect the lathe from power

before using the spindle lock feature. Never

resume turning operations without making

sure that the spindle lock is disengaged and

the spindle turns freely by hand. Otherwise

machine damage could result.

figure 24. Motor lock and height levers.

height

Lever

figure 25. spindle lock lever and viewing

window.

numbered

holes

shown

through

viewing

Window.

spindle Lock

Lock Lever