Mounting to shop floor notice – Grizzly G0694 User Manual

Page 17

Model G0694 (Mfg. Since 10/09)

-15-

Mounting to Shop

floor

NOTICE

To ensure long life from you lathe and good

turning results, make sure the bedways

are level side-to-side and front-to-back.

Re-check the bedways two weeks after the

initial placement of the machine, then annu-

ally thereafter.

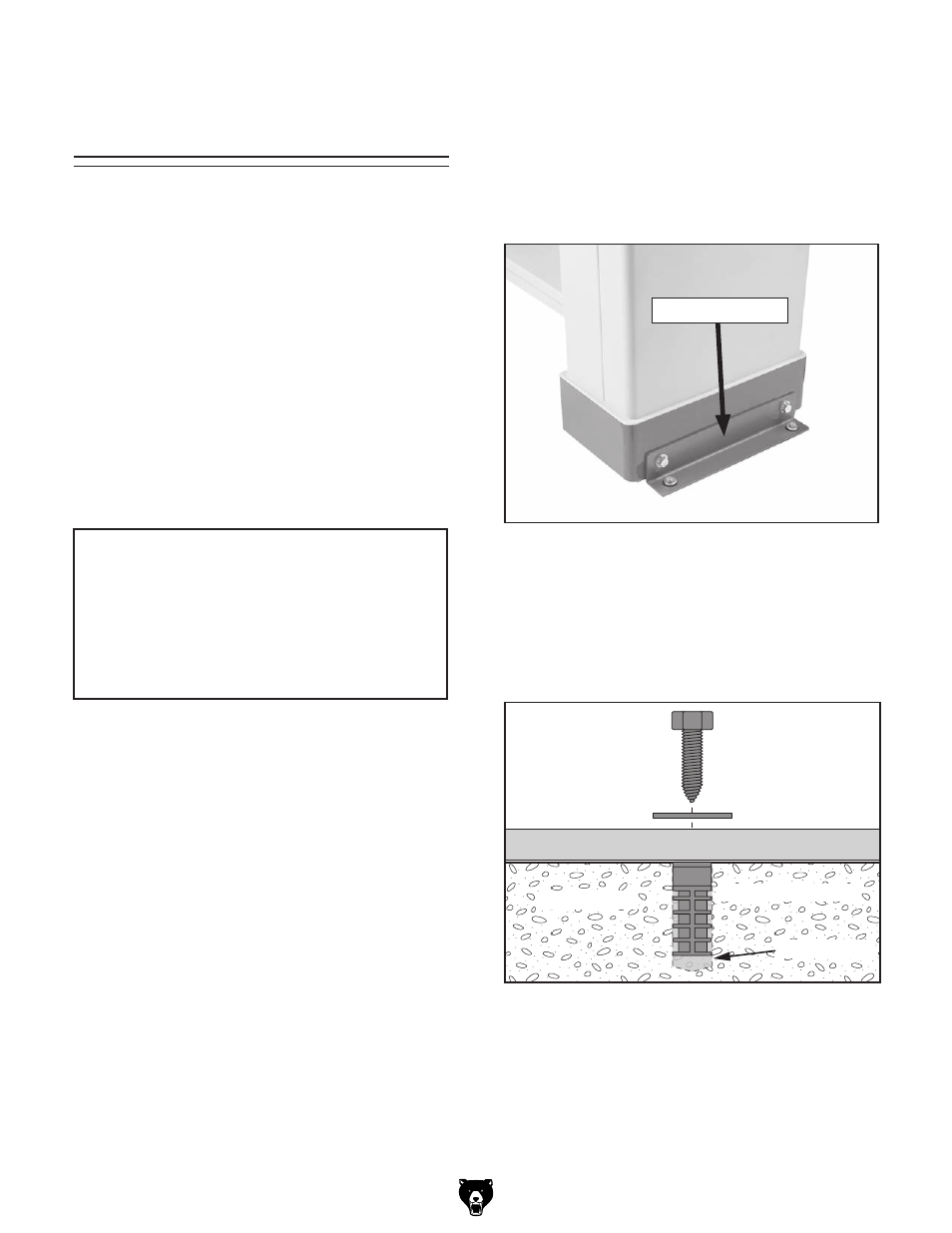

figure 7. right side mounting flange.

Mounting Flange

Use a precision level to make sure the bedways

are level side-to-side and front-to-back. if neces-

sary, place metal shims under the cabinets and

mounting flanges.

the mounting flanges on either side of the lathe

will accept

3

⁄

8

" mounting hardware (see

figure 7).

securing the machine to the floor prevents it from

tipping or shifting and reduces operational vibra-

tion. on the other hand, securing the machine to

the floor reduces future mobility.

if your machine will be installed in an industrial or

workplace setting, or if it is permanently connect-

ed (hardwired) to the power supply, local codes

may require that it be fastened to the floor.

if not required by any local codes, securing the

machine to the floor is an optional step. if you

choose not to secure the machine to the floor,

we recommend placing it on machine mounts,

because they give you an easy way to level the

machine and feature vibration-absorbing pads.

figure 8. typical fasteners for mounting to

concrete floors.

Machine Base

Concrete

Lag Screw

Lag Shield Anchor

Flat Washer

Drilled Hole

Bolting to concrete floors

Lag shield anchors with lag screws (see below)

are a popular way to anchor machinery to a con-

crete floor. however, always be sure the approved

methodology when local codes apply.