Adjusting backlash – Grizzly VS MILLING MACHINE G0669X User Manual

Page 49

g0669X precision 10" x 54" Vs Milling Machine

-47-

Adjusting backlash

Leadscrew backlash is the amount of motion the

leadscrew rotates before the device begins to

move. Leadscrews always have a certain amount

of backlash that will increase with wear. generally,

0.005"–0.010" of backlash is acceptable.

tools Needed

Qty

t-handle hex Wrench 5mm .............................. 1

hex Wrench 8mm .............................................. 1

Wrench or socket 19mm ................................... 1

to adjust leadscrew backlash:

1. disConneCt the MiLL FroM poWer!

2. remove the front way cover.

3. Move the table and saddle all the way for-

ward, then remove the ball handle.

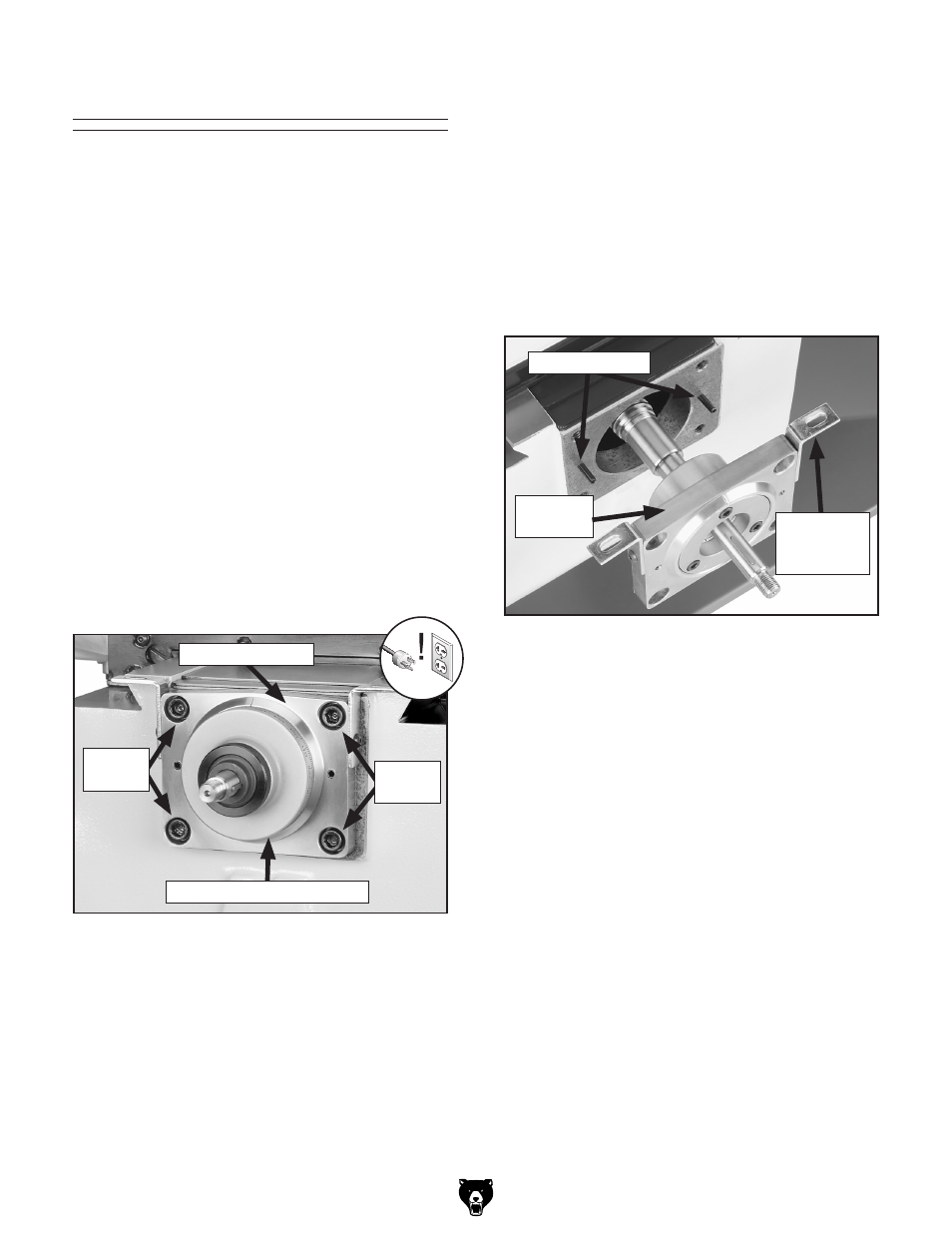

4. remove the four cap screws shown in figure

65 that hold the bearing housing to the sad-

dle.

5. slide the graduated dial assembly off the

leadscrew, then remove the key from the end

of the leadscrew.

6. Carefully loosen the bearing housing from

the alignment pins, then remove it from the

leadscrew (see

figure 66).

Note: If you need to pry the bearing hous-

ing loose, do so carefully and evenly from

all sides to avoid damaging the bearing and

leadscrew.

figure 66. Cross feed bearing housing and

alignment pins.

alignment pins

Bearing

housing

Way Cover

Mounting

Flange

figure 65. Cross feed graduated dial assembly

and bearing housing with ball handle removed.

Cap

screws

Cap

screws

graduated dial assembly

Bearing housing