Ram way, Longitudinal power feed gearing, Vertical leadscrew bevel gears – Grizzly VS MILLING MACHINE G0669X User Manual

Page 41

g0669X precision 10" x 54" Vs Milling Machine

-39-

Ram Way

Lubricant

frequency

Qty

iso 68 sae 20W

Bearing and gear

Lubricant

every

40 hours

of operation

thin

Coat

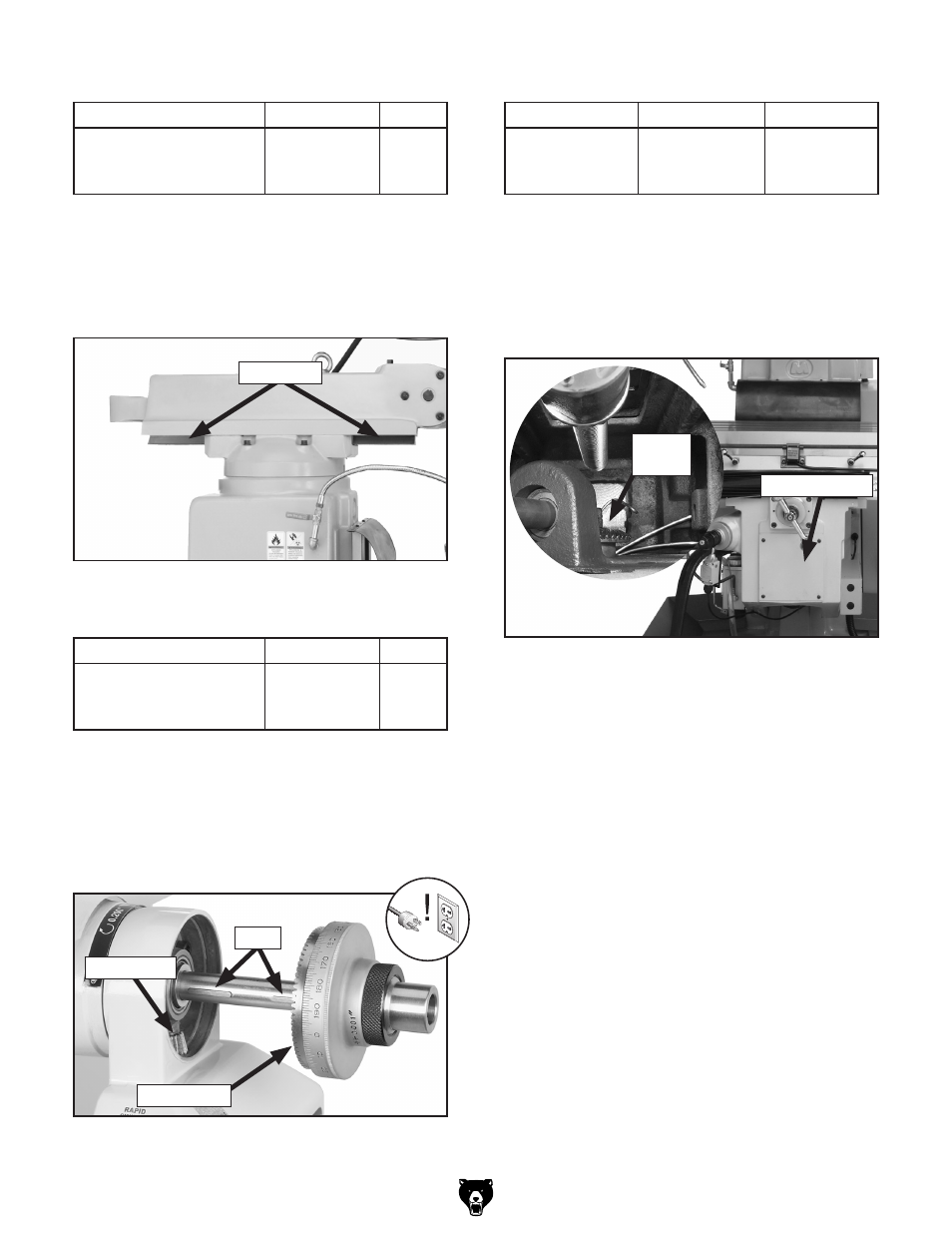

Move the ram forward and backward as neces-

sary to access the entire length of the ram way

(see

figure 55). Use mineral spirits and shop rag

to wipe the old lubricant and debris from the way

surfaces, then brush on a thin coat of lubricant.

Longitudinal Power feed Gearing

Lubricant

frequency

Qty

Multi-purpose gear

grease

every 120

hours of

operation

thin

Coat

remove the right longitudinal ball handle, spac-

ers, and leadscrew keys. slide the graduated dial

assembly out from the power feed unit. apply a

thin coat of lubricant to the brass and drive gears

shown in

figure 56, then re-install the parts in

reverse order.

figure 56. Longitudinal power feed gearing.

Brass gear

drive gear

Vertical Leadscrew bevel Gears

Lubricant

frequency

Qty

Multi-purpose

gear grease

every

40 hours

of operation

thin Coat

open the access panel on the front of the saddle

shown in

figure 57. Using mineral spirits and a

shop rag, reach through the opening and clean

old lubricant and debris from the vertical bevel

gears. apply a thin coat of lubricant, then replace

the access panel.

figure 57. Vertical leadscrew bevel gears.

access panel

Bevel

gears

Keys

figure 55. ram way.

ram Way