Drive belt tensioning – Grizzly VS MILLING MACHINE G0669X User Manual

Page 44

-42-

g0669X precision 10" x 54" Vs Milling Machine

Drive belt

tensioning

power is transferred from the motor to the spindle

with a heavy-duty drive belt. With normal use, this

belt will gradually stretch over time. When it does,

perform the following procedures to re-tension it.

tools Needed

Qty

phillips screwdriver ........................................... 1

Wrench 13mm ................................................... 1

Wrench 17mm.................................................... 1

to check/tension the drive belt:

1. disConneCt the MiLL FroM poWer!

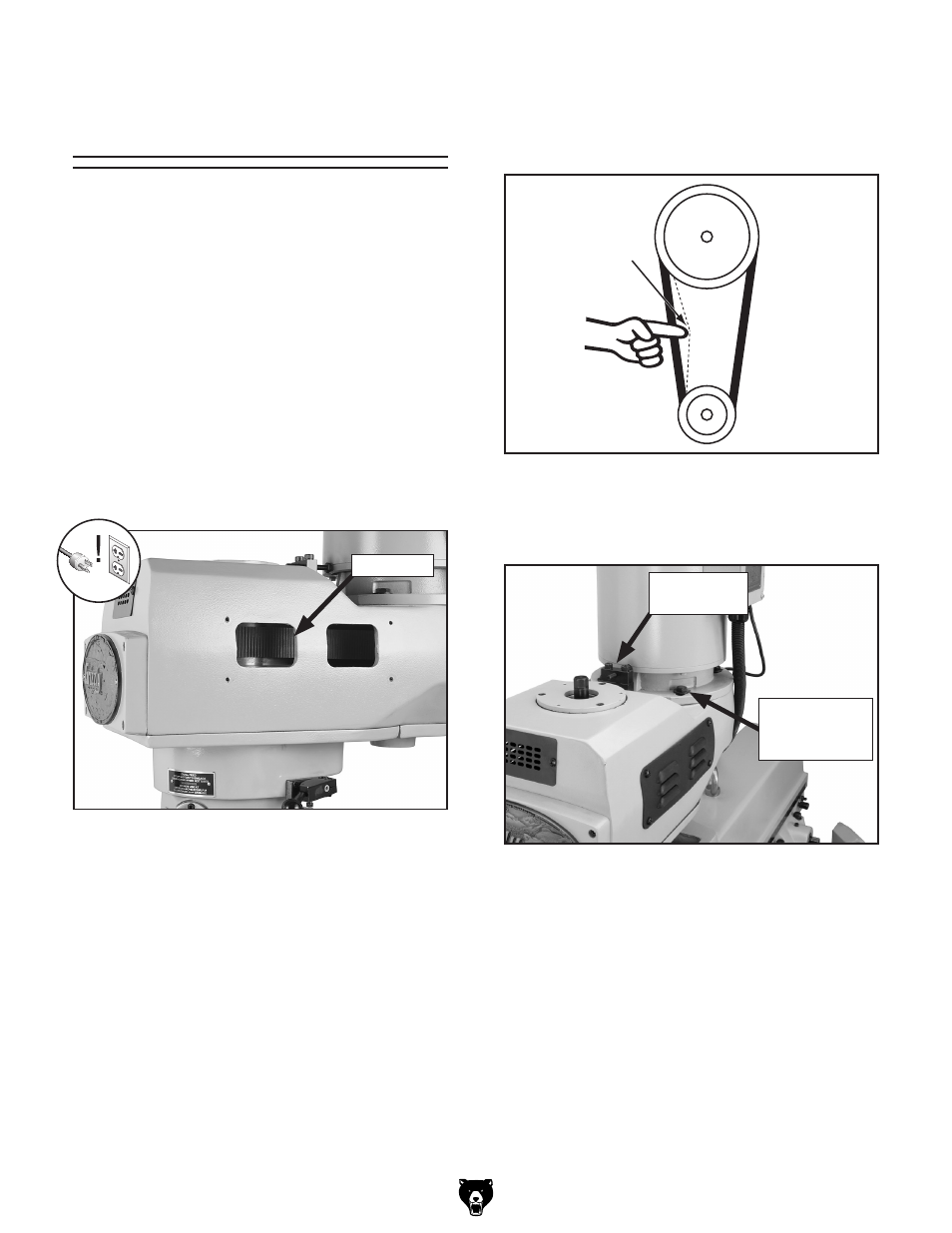

2. remove the belt access panel from the right

side of the head (see

figure 59).

figure 59. access panel removed to access

drive belt.

drive Belt

3. Check the belt tension. When moderate pres-

sure is applied to the belt between the pulleys

(see

figure 60), there should be approxi-

mately

1

⁄

2

" of belt deflection.

EjaaZn

9Z[aZXi^dc

EjaaZn

figure 60. Checking for belt deflection.

4. Loosen the four motor mount hex bolts (see

figure 61).

5. push the motor back until there is the correct

amount of belt deflection, then tighten the

adjustment hex bolt in and against the motor

mounting plate to secure the setting.

6. re-tighten the motor mount hex bolts.

7. re-install the drive belt access panel before

beginning milling operations.

figure 61. Motor mount and drive belt tension

adjustment hex bolts.

adjustment

hex Bolt

Motor Mount

hex Bolt

(1 of 4)