Troubleshooting, Motor & electrical – Grizzly VS MILLING MACHINE G0669X User Manual

Page 45

g0669X precision 10" x 54" Vs Milling Machine

-43-

review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel-

ops. if you need replacement parts or you are unsure of your repair skills, then feel free to call our technical

support at (570) 546-9663.

SECtION 7: SERVICE

troubleshooting

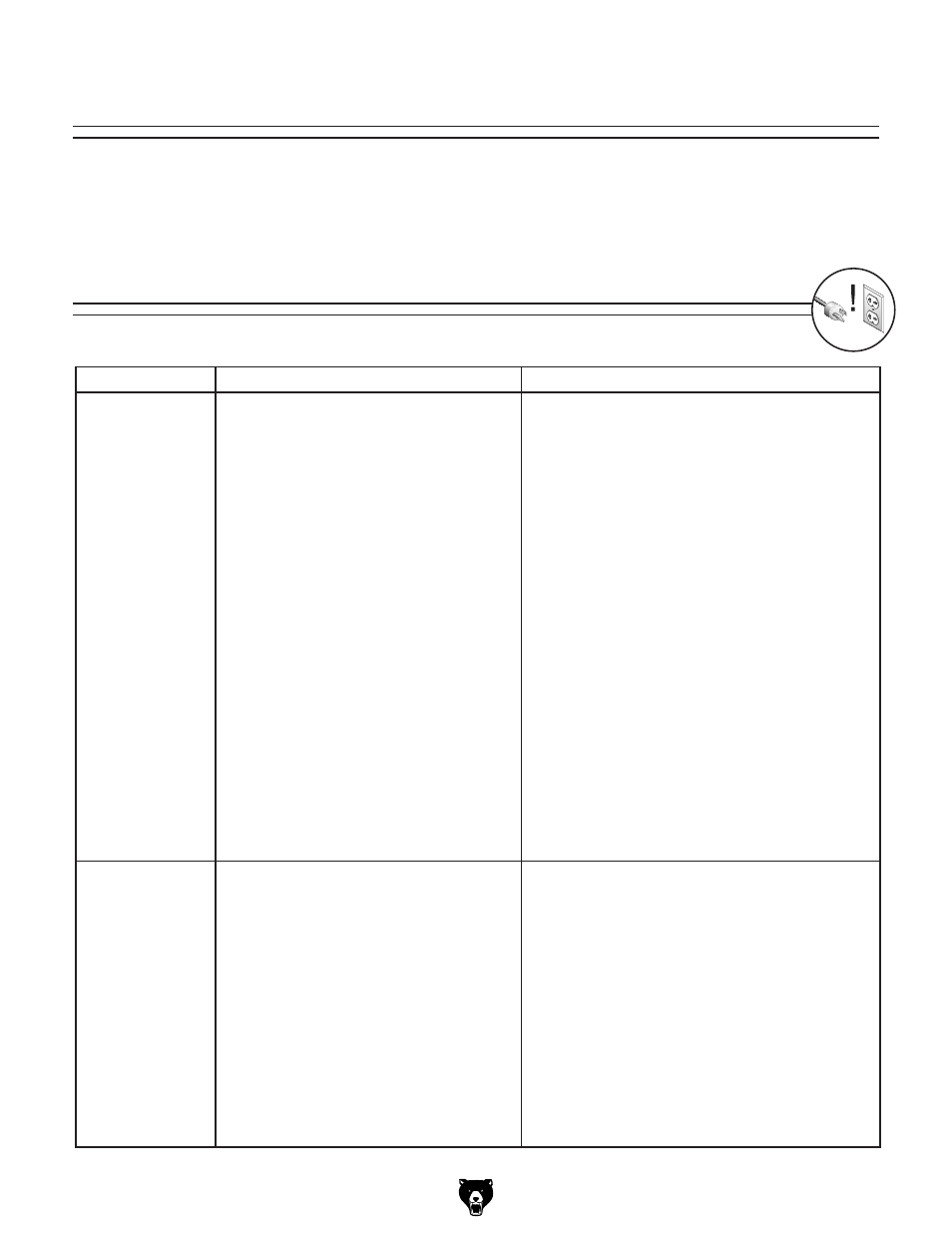

Motor & Electrical

symptom

possible Cause

possible solution

Machine does not

start or a breaker

trips.

1. emergency stop push-button is engaged or

is at fault.

2. Main power switch on electrical cabinet

door turned oFF or is at fault.

3. electrical cabinet door is open engaging

safety switch; switch is at fault.

4. power supply switched oFF or is at fault.

5. plug/receptacle is at fault or wired

incorrectly.

6. Machine fuse has blown.

7. Motor connection wired incorrectly.

8. relay switch is at fault.

9. Wall fuse/circuit breaker is blown/tripped.

10. Contactor not getting energized/has burnt

contacts.

11. Wiring is open/has high resistance.

12. Motor on button switch is at fault.

13. transformer is at fault.

14. Motor is at fault.

15. Frequency drive is at fault.

1. rotate clockwise slightly until it pops out/replace it.

2. turn the main power switch on; replace.

3. Close and secure electrical cabinet door; replace

switch.

4. ensure power supply is switch on; ensure power

supply has the correct voltage.

5. test for good contacts; correct the wiring.

6. replace fuse.

7. Correct motor wiring connections (

Page 55).

8. replace relay switch.

9. ensure circuit size is suitable for this machine;

replace weak breaker.

10. test for power on all legs and contactor operation.

replace unit if it is at fault.

11. Check for broken wires or disconnected/corroded

connections, and repair/replace as necessary.

12. replace on button switch.

13. test/repair/replace.

14. test/repair/replace.

15. test/replace.

Machine stalls or is

overloaded.

1. Feed rate/cutting speed too fast for task.

2. Workpiece alignment is poor.

3. dull or incorrect cutting tool.

4. drive belt loose or worn.

5. gearbox is at fault.

6. Motor connection is wired incorrectly.

7. plug/receptacle is at fault.

8. pulley/sprocket slipping on shaft.

9. Motor bearings are at fault.

10. Machine is undersized for the task.

1. decrease feed rate/cutting speed.

2. eliminate workpiece binding; use vise or clamps as

required for workpiece alignment control.

3. Use sharp and correct cutting tool for the operation.

4. re-tension drive belt (

Page 42); replace.

5. select appropriate spindle speed range; replace

broken or slipping gears.

6. Correct motor wiring connections.

7. test for good contacts; correct the wiring.

8. replace loose pulley/shaft.

9. test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

10. Use smaller sharp tooling; reduce the feed rate;

reduce the spindle rpM; use coolant.