Motor & electrical (continued) – Grizzly VS MILLING MACHINE G0669X User Manual

Page 46

-44-

g0669X precision 10" x 54" Vs Milling Machine

Motor & Electrical (continued)

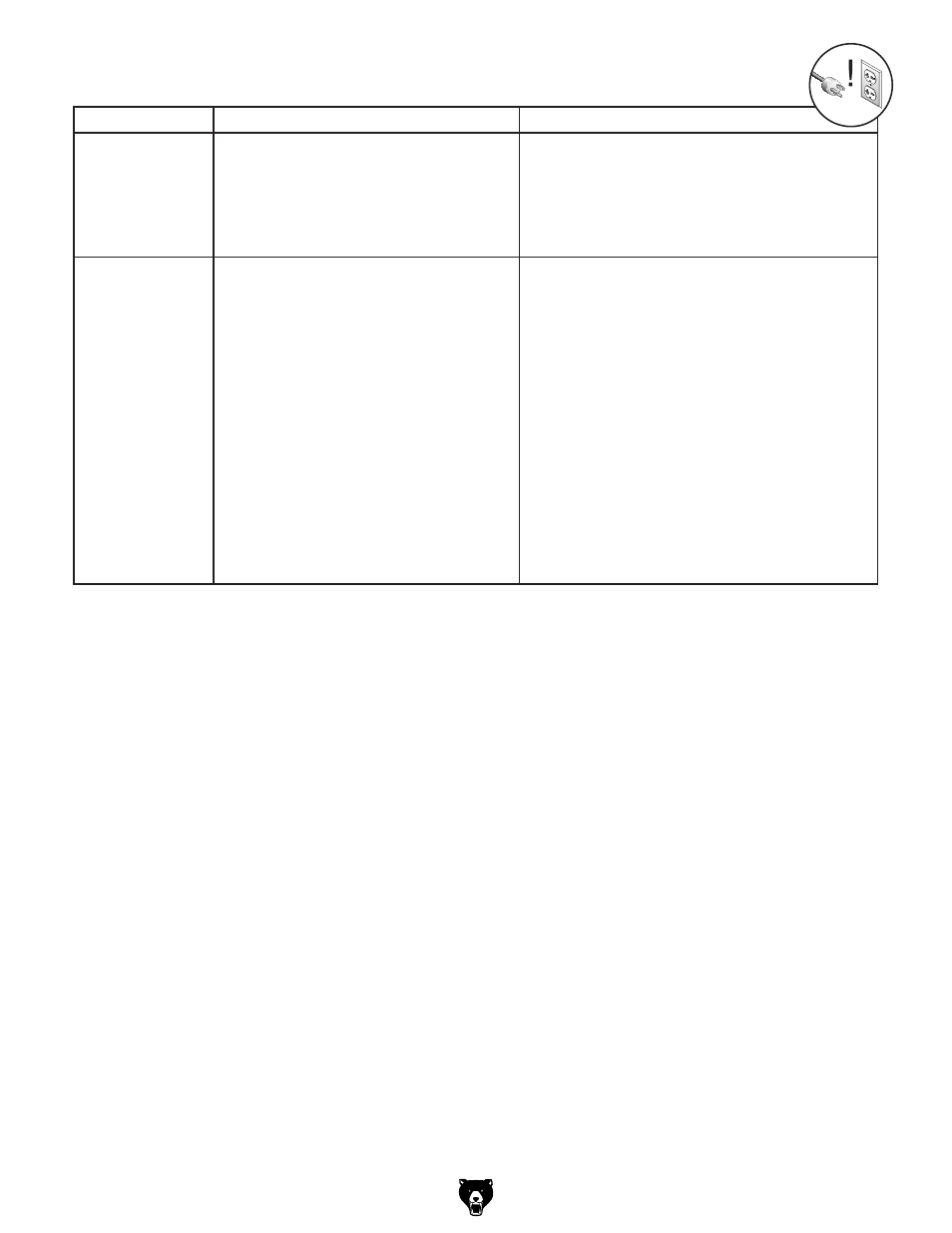

symptom

possible Cause

possible solution

Machine stalls or is

overloaded.

11. Contactor not getting energized or has poor

contacts.

12. Motor has overheated.

13. spindle rotation switch at fault.

14. Motor is at fault.

15. Frequency drive at fault.

11. test for power on all legs and contactor operation.

replace if at fault.

12. Let cool, Clean off motor, and reduce workload.

13. turn switch to FWd/reV; replace bad switch.

14. test/repair/replace.

15. test/replace.

Machine

has

vibration or noisy

operation.

1. Chuck or cutter is at fault.

2. Workpiece alignment is poor.

3. Motor or component is loose.

4. pulley is loose.

5. Motor mount loose/broken.

6. Machine is incorrectly mounted or sits

unevenly.

7. Motor fan is rubbing on fan cover.

8. Motor bearings are at fault.

9. gearbox is at fault.

1. replace out-of-round chuck; replace/resharpen

cutter; use appropriate feed rate and cutting rpM.

2. eliminate workpiece binding; use vise or clamps as

required for workpiece alignment control.

3. inspect/replace stripped or damaged bolts/nuts, and

re-tighten with thread locking fluid.

4. realign/replace shaft, pulley, setscrew, and key as

required.

5. tighten/replace.

6. tighten/replace anchor studs in floor; relocate/shim

machine.

7. replace dented fan cover; replace loose/damaged

fan.

8. test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

9. rebuild gearbox for bad gear(s)/bearing(s).