Tensioning/ replacing v-belts – Grizzly G9249 User Manual

Page 53

g9249 12" x 37" Belt drive gap Bed lathe

-51-

Tensioning/

Replacing V-Belts

Adjusting Motor V-Belt

Tools Needed

Qty

Wrench 18mm ................................................... 1

To adjust the motor V-belt tension:

1. disConneCt lAthe FroM poWer!

2. push the belt tensioning lever back to tension

both belts (see

figure 90).

figure 90. V-belt tensioning lever.

Belt

tensioning

lever

3. From the back of the lathe, check the motor

V-belt deflection when moderate pressure is

placed on the V-belt mid-way between the

pulleys—it should be approximately

1

⁄

2

" (see

figure 91).

EjaaZn

9Z[aZXi^dc

EjaaZn

figure 91. Checking motor V-belt tension.

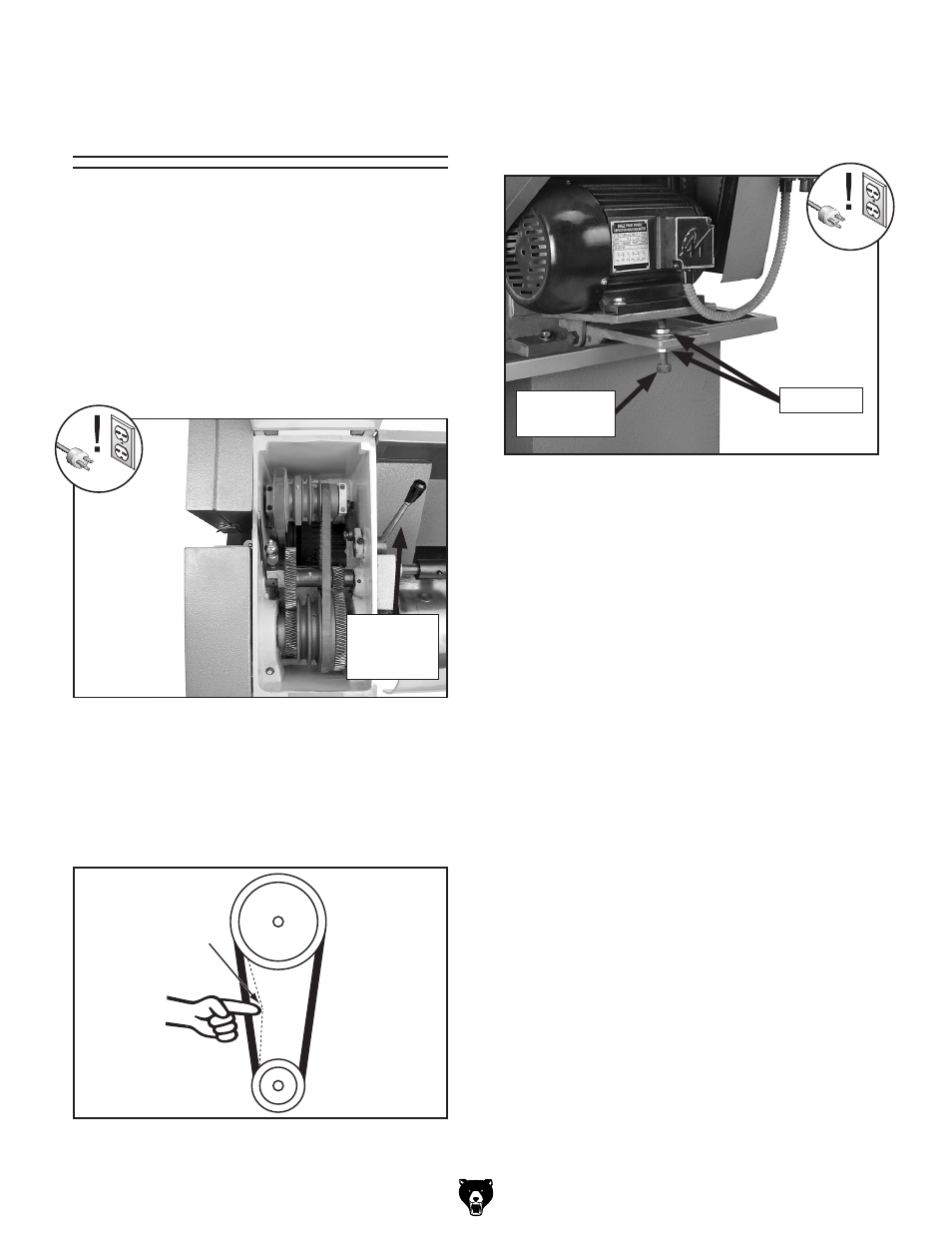

4. to adjust the motor V-belt tension, loosen

the jam nuts shown in

figure 92, then adjust

the tensioning hex bolt to raise or lower the

motor.

5. re-check the V-belt deflection, and, when

you are satisfied with the setting, re-tighten

the jam nuts.

Replacing Motor V-Belt

Tools Needed

Qty

hex Wrench 5mm .............................................. 1

To replace the motor V-belt:

1. disConneCt lAthe FroM poWer!

2. pull the belt tensioning lever forward to

release V-belt tension, then roll the motor

V-belt off the motor pulley.

3. raise the headstock cover.

figure 92. Motor V-belt tensioning hex bolt and

jam nuts.

tensioning

hex Bolt

Jam nuts