Centers – Grizzly G9249 User Manual

Page 28

-26-

g9249 12" x 37" Belt drive gap Bed lathe

Always use a low spindle speed when

machining non-cylindrical or off-center

workpieces to avoid ejecting the workpiece

from the holding device at a high rate of

speed. failure to heed this warning could

lead to serious personal injury or property

damage.

using the faceplate

the faceplate can be used to turn non-cylindrical

parts or for off-center turning by clamping the

workpiece to it.

To mount a workpiece on the faceplate:

1. disConneCt lAthe FroM poWer!

2. use a piece of wood to protect the bedways.

3. secure the workpiece on the faceplate with

a minimum of three independent clamping

devices (see

figure 30 for an example).

Note: Take into account the rotation and

cutting forces that will be applied to the

workpiece when clamping it to the faceplate.

figure 30. example of a non-cylindrical

workpiece mounted on the faceplate.

Faceplate

non-Cylindrical

Workpiece

Clamp

centers

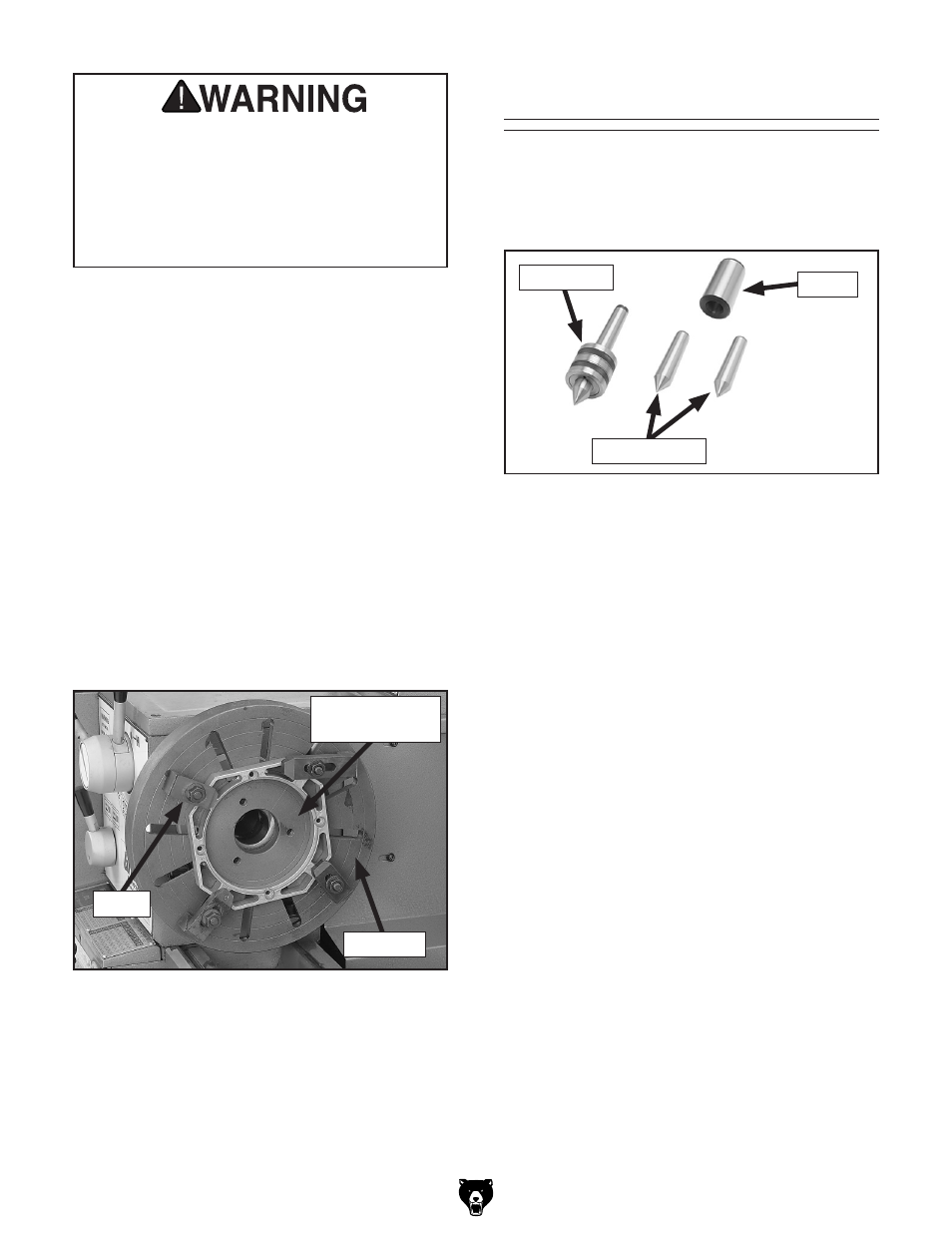

the Model g9249 includes one Mt#3 live center

and two Mt#3 dead centers (see

figure 31). the

supplied Mt#5–Mt#3 spindle sleeve fits into the

spindle taper to hold an Mt#3 center or tool.

figure 31. Centers and spindle sleeve.

sleeve

dead Centers

live Center

the live center tip will rotate independently of the

spindle or quill. the dead centers will spin with

the spindle and remain stationary when used in

the quill. use these devices as required by your

operation.

the steps to install and remove a center into

the tailstock quill are detailed in the previous

Tailstock subsection on Page 27.

Installing a Sleeve and center into

the Spindle

1. Clean away any grime or oily substance from

the tapered mating surfaces of the sleeve

and center.

2. install the center into the spindle sleeve, then

seat the assembly into the spindle.