Headstock change gears, Headstock idler pulley shaft, Headstock gears – Grizzly G9249 User Manual

Page 50: Headstock spindle pulley shaft, Feed rate gearbox oil

-48-

g9249 12" x 37" Belt drive gap Bed lathe

Headstock change Gears

Lubricant

frequency

Qty

Multi-purpose

gear grease

every

8 hours

of operation

one pump to

Fittings;

thin Coat to

gears

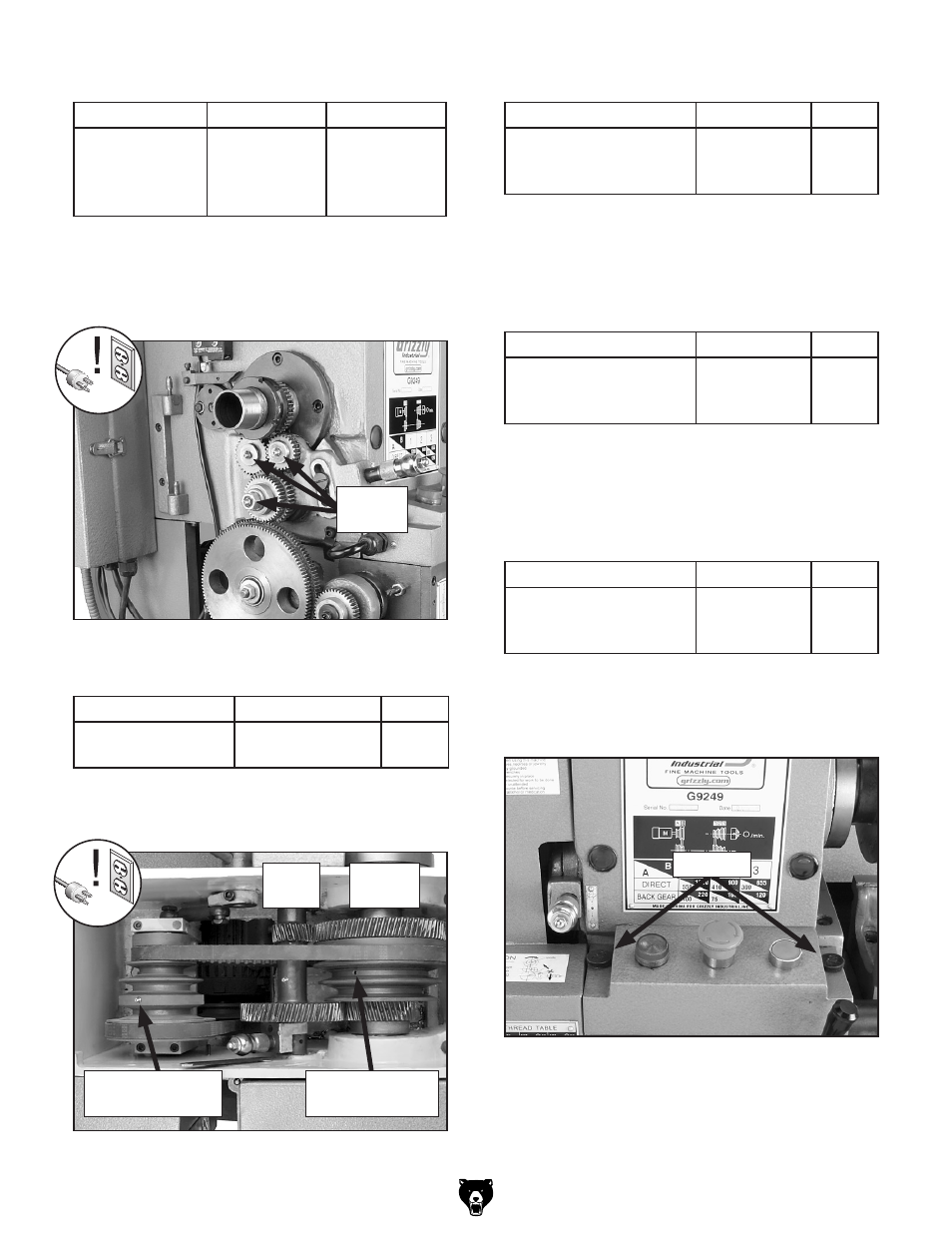

Add one pump from a grease gun to the three

headstock grease fittings shown in

figure 80.

use a brush to apply a thin coat of grease to the

gear teeth.

figure 80. headstock grease fittings.

grease

Fittings

Headstock Idler Pulley Shaft

Lubricant

frequency

Qty

Multi-purpose

gear grease

every 8 hours

of operation

one

pump

Add one pump from a grease gun to the idler pul-

ley grease fitting shown in

figure 81.

figure 81. headstock pulley shaft lubrication

points.

spindle

gears

Back

gears

spindle pulley

shaft set screw

idler pulley shaft

grease Fitting

Headstock Gears

Lubricant

frequency

Qty

Multi-purpose gear

grease

every

8 hours

of operation

thin

Coat

use a brush to apply a thin coat of grease to the

gear teeth of the spindle and back gears (see

figure 81).

Headstock Spindle Pulley Shaft

Lubricant

frequency

Qty

iso 68 sAe 20W

Bearing and gear

lubricant

every

8 hours

of operation

2–3

drops

remove the spindle pulley shaft set screw shown

in

figure 81, add 2–3 drops of lubricant, then re-

install the set screw.

feed Rate Gearbox Oil

Lubricant

frequency

Qty

iso 68 sAe 20W

Bearing and gear

lubricant

every

8 hours

of operation

2–3

drops

remove the oil plugs on either side of the control

panel (see

figure 82), add 2–3 drops of lubricant,

then replace the oil plugs.

figure 82. Feed rate gearbox oil plugs.

oil plugs