Site considerations, Lathe assembly & placement – Grizzly G9249 User Manual

Page 16

-14-

g9249 12" x 37" Belt drive gap Bed lathe

floor Load

refer to the

Machine Data Sheet on Page 4 for

the weight and footprint specifications of your

machine. some residential floors may require

additional reinforcement to support both the

machine and operator.

Placement Location

Consider existing and anticipated needs, size of

material to be processed through each machine,

and space for auxiliary stands, work tables or

other machinery when establishing a location for

your new machine. see

figure 7 for the minimum

working clearances.

children and visitors may be

seriously injured if unsuper-

vised around this machine.

Lock entrances to the shop

or disable start switch or

power connection to prevent

unsupervised use.

Site considerations

-*

)(

figure 7. Model g9249 working clearances.

Lathe Assembly &

Placement

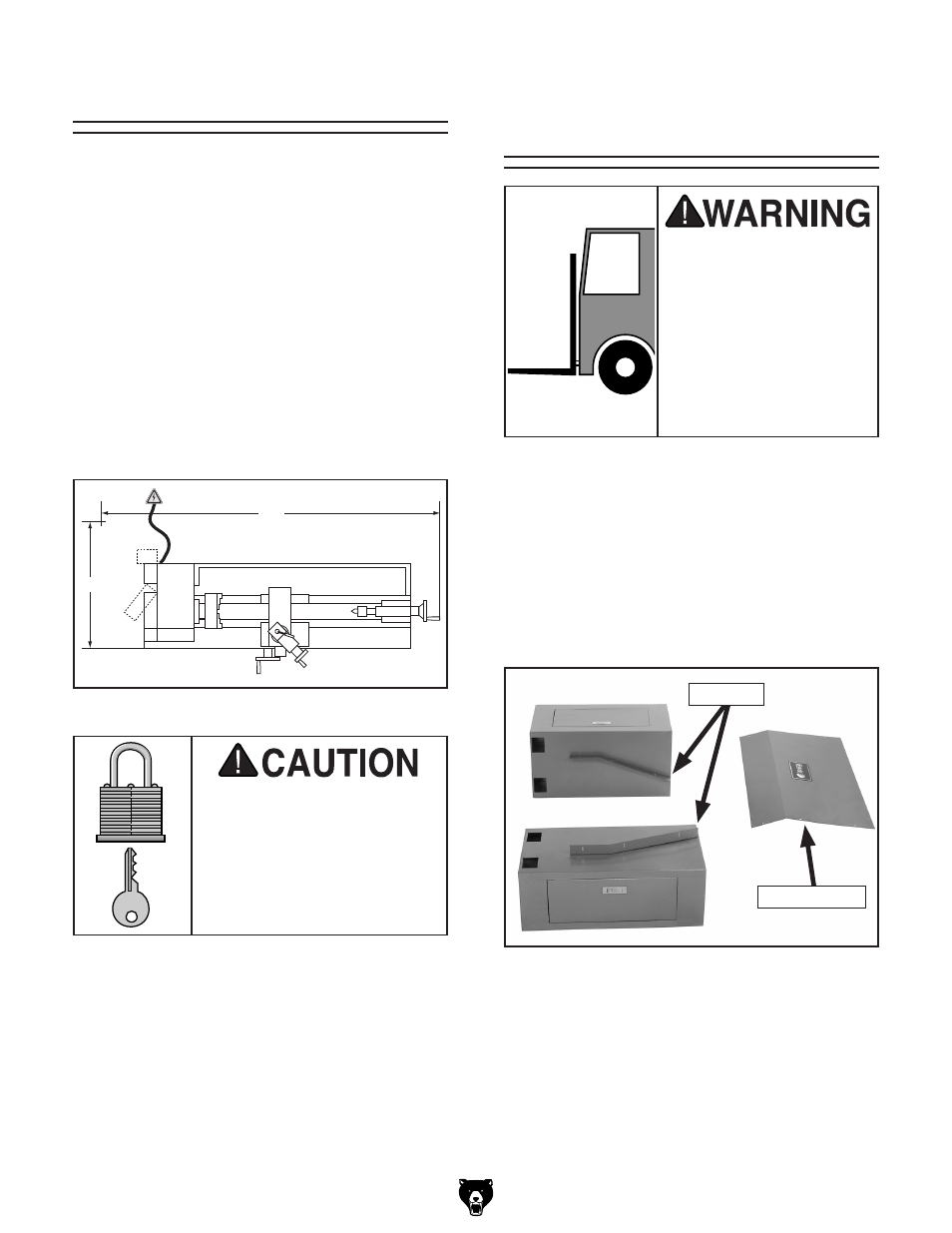

The Model G9249 is a

heavy machine. Serious

personal injury may occur

if safe moving methods are

not used. Get assistance

and use power equipment

(rated for at least 1500

lbs.) to move the ship-

ping crate and remove the

machine from the crate.

To assemble and move the lathe:

1. place the cabinets at the prepared site for the

lathe.

2. Attach the center panel brackets to the

inside of the cabinets with six M6-1 x phillips

head screws and flat washers, as shown in

figure 8.

figure 8. Center panel brackets installed.

Center panel

Brackets

3. stand the cabinets upright, then attach the

center panel to the brackets with the remain-

ing M6-1 x 10 phillips head screws, flat wash-

ers, and M6-1 hex nuts.